Lodging-resistant controlled release blend bulk fertilizer for direct-sowing rice as well as preparation method and application thereof

An anti-lodging and fertilizer technology, applied in fertilization methods, applications, inorganic fertilizers, etc., can solve the problems of insufficient quick-acting nutrients, unsuitable for popularization and application, and high fertilizer costs, and achieves a high proportion of controlled-release nutrients, which is conducive to large-scale promotion. , the effect of improving the quality of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A lodging-resistant controlled-release blended fertilizer for direct-seeding rice, a preparation method and application thereof according to a preferred embodiment of the present invention;

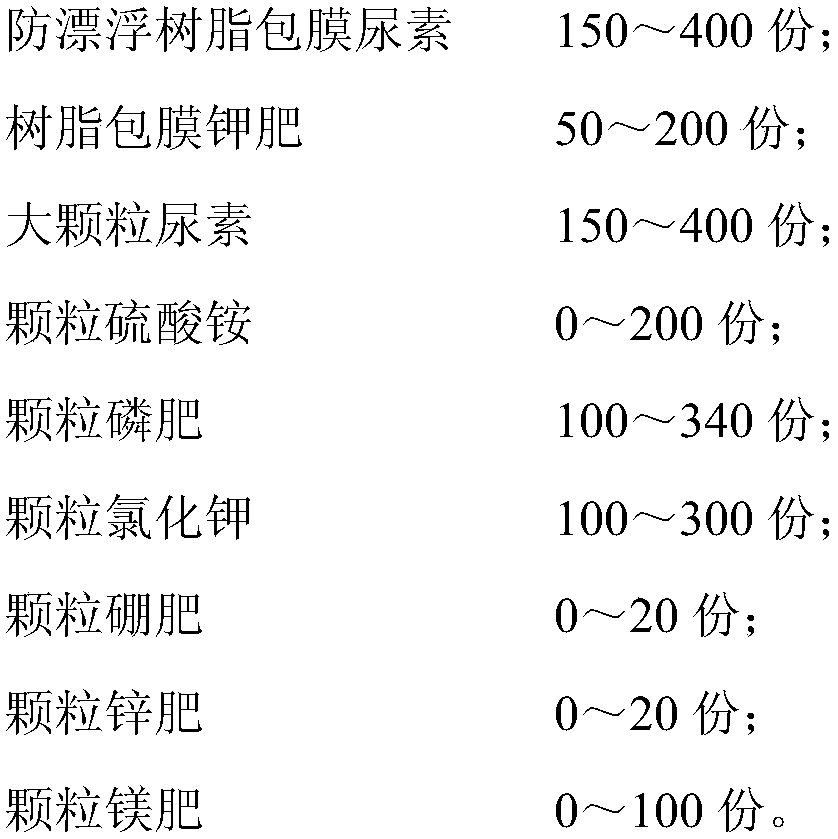

[0030] The lodging-resistant and controlled-release blended fertilizer for direct-seeding rice consists of the following components in parts by weight:

[0031] Nitrogen, phosphorus and potassium are 27-9-13, nitrogen control 13, and potassium control 4%:

[0032]

[0033] Wherein the mass percentage of nitrogen in the anti-floating resin-coated urea is 44%, the mass percentage of potassium in the resin-coated potassium chloride is 57%, and the mass percentage of nitrogen in the granular monoammonium phosphate is 11%. %, the mass percentage of phosphorus is 44%, the mass percentage of boron in the granular boron fertilizer is 15%, and the mass percentage of zinc in the granular zinc fertilizer is 30%.

[0034] The present invention prepares the method for the anti-lodging contr...

example 2

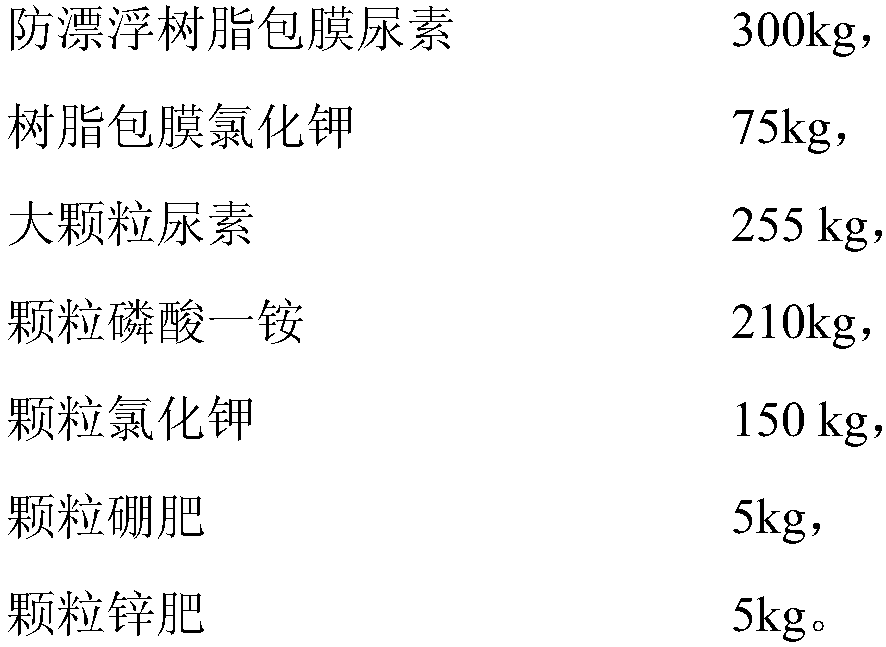

[0038] A lodging-resistant controlled-release blended fertilizer for direct-seeding rice, a preparation method and application thereof according to a preferred embodiment of the present invention;

[0039] The lodging-resistant and controlled-release blended fertilizer for direct-seeding rice consists of the following components in parts by weight:

[0040] Nitrogen, phosphorus and potassium are 27-9-13, nitrogen control 13, and potassium control 4%:

[0041]

[0042] Wherein the mass percentage of nitrogen of anti-floating resin-coated urea is 44%, the mass percentage of potassium of resin-coated potassium nitrate is 44%, the mass percentage of nitrate nitrogen is 12%, and the granular monoammonium phosphate The mass percentage of nitrogen in the medium is 11%, the mass percentage of phosphorus is 44%, the mass percentage of boron in the granular boron fertilizer is 15%, and the mass percentage of zinc in the granular zinc fertilizer is 30%. .

[0043] The present invent...

example 3

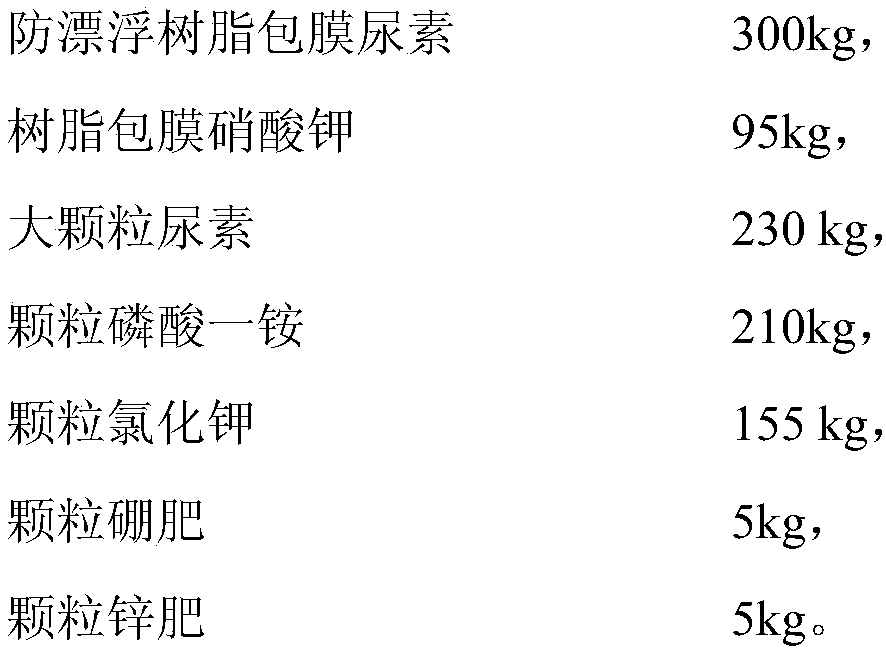

[0047] A lodging-resistant controlled-release blended fertilizer for direct-seeding rice, a preparation method and application thereof according to a preferred embodiment of the present invention;

[0048] The lodging-resistant and controlled-release blended fertilizer for direct-seeding rice consists of the following components in parts by weight:

[0049] Nitrogen, phosphorus and potassium are 25-10-14 respectively, nitrogen control 15%, potassium control 4%:

[0050]

[0051]

[0052] Wherein the mass percentage of nitrogen in anti-floating resin-coated urea is 44%, the mass percentage of potassium in resin-coated potassium chloride is 57%, and the mass percentage of nitrogen in granular monoammonium phosphate is 11%, The mass percentage of phosphorus is 44%, the mass percentage of boron in the granular boron fertilizer is 15%, the mass percentage of zinc in the granular zinc fertilizer is 30%, and the mass percentage of magnesium in the granular magnesium fertilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com