AlCrSiN coating with intermediate layer with Si content gradient change, and preparation method

A gradient change, intermediate layer technology, applied in the field of AlCrSiN coating preparation of the intermediate layer, to achieve low friction coefficient, easy industrial production, and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

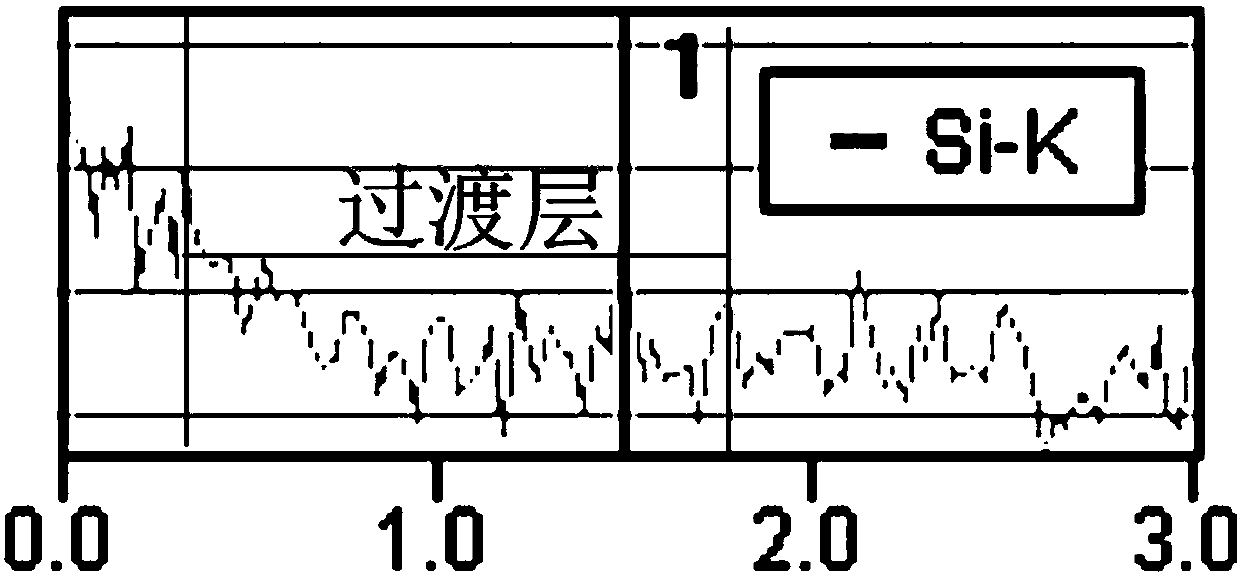

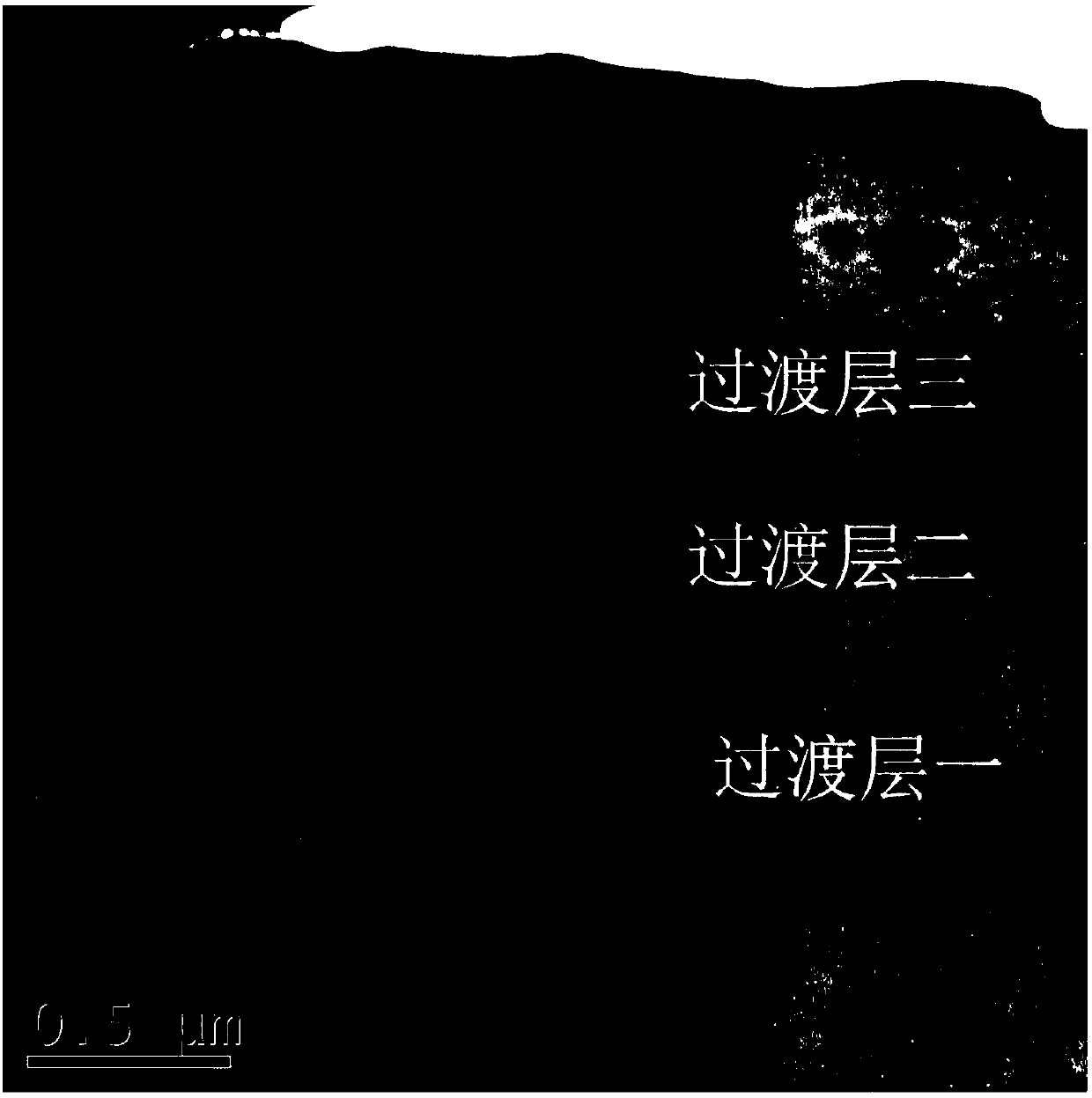

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the AlCrSiN composite coating tool cutting life coating of the present embodiment is as follows:

[0028] Fix the pretreated high-speed steel cutter evenly on the turntable in the furnace cavity, control the rotation speed of the turntable to 3rpm, and pump to a background vacuum of 1×10 -4 ~2×10 -4 Pa, turn on the heater at the same time, and raise the temperature to 480°C;

[0029] Open the Ar gas flow valve, control the vacuum in the furnace chamber to about 4.0Pa, reduce the negative bias of the substrate to -180V, turn on the cylindrical Ti target as the arc target, and control the target current to 80A to complete the high-energy ion bombardment on the surface of the substrate. Etching cleaning, cleaning time 45min;

[0030] Cylindrical Ti target closed, N open 2 The flow valve controls the negative bias voltage of the substrate to -60V, adjusts the vacuum in the furnace chamber to about 3.5Pa, and the N 2 Input in the way of constant...

Embodiment 2

[0036] The composite coating in this embodiment does not use an intermediate layer, and the AlCrSiN composite coating consists of an AlCrN primer layer and an AlCrSiN working layer, which is denoted as AlCrSiN-1. Concrete preparation process is as follows:

[0037]Fix the pretreated high-speed steel cutter evenly on the turntable in the furnace cavity, control the rotation speed of the turntable to 3rpm, and pump to a background vacuum of 1×10 -4 ~2×10 -4 Pa, turn on the heater at the same time, and raise the temperature to 480°C;

[0038] Open the Ar gas flow valve, control the vacuum in the furnace chamber to about 4.0Pa, reduce the substrate negative bias to -180V, turn on the cylindrical Ti arc target, control the target current to 80A, and complete the etching of the substrate surface by high-energy ion bombardment Cleaning, the cleaning time is 45min;

[0039] Close cylindrical Ti arc target, open N 2 The flow valve controls the negative bias voltage of the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com