Preparation method for highly-weatherable ultraviolet-curable polyurethane coating

A technology of polyurethane coatings and high weather resistance, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as carbon-carbon single bond structure damage, and achieve high double bond conversion rate, good compatibility, and adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

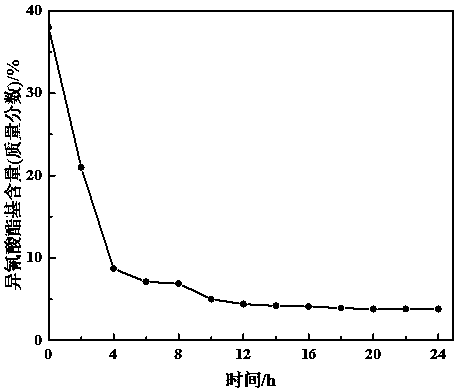

[0029] (1) 100 g of epoxy-terminated polydimethylsiloxane was uniformly dispersed in ethyl acetate by ultrasound, the dispersion system was placed in the reactor for use, the system was uniformly heated to 85 ℃, and at the same time in 5 h Slowly add 20 g of acrylic acid with 0.25 g of benzyl triethylammonium chloride (TEBA) dissolved in it, keep it for 12 hours, and adjust the acid value of the reaction system to no more than 15 mg KOH / g;

[0030] (2) Place 100 g of the acrylic modified polydimethylsiloxane obtained in step (1) in the reactor, heat the system uniformly to 30 ℃, and slowly add 50 g of 4,4'-two Phenylmethane diisocyanate and 3.5 g of dibutyltin dilaurate were reacted for 12 h to obtain a prepolymer of diisocyanate and modified organosilicon compound;

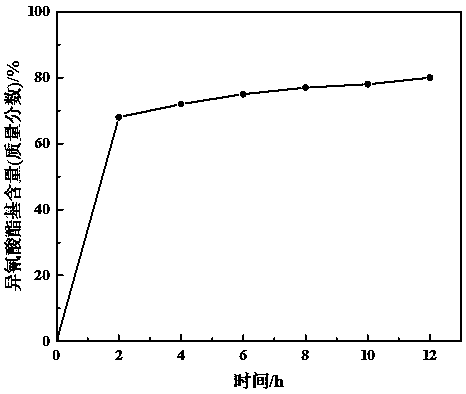

[0031] (3) Place 100 g of the prepolymer of diisocyanate and modified organosilicon compound in the reactor of step (2), heat the system uniformly to 60 ℃, and slowly add 210 g of trimethylolpropane diacrylic acid dro...

Embodiment 2

[0034] Compared with Example 1, the amount of terminal epoxy polydimethylsiloxane in the first step is changed to 105 g, and other conditions remain unchanged.

Embodiment 3

[0036] Compared with Example 1, the reaction temperature of the system in the first step was changed to 95°C, and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com