Alkali-modified pig manure biochar and preparation method and application thereof

A biochar and alkali modification technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of inability to remove pollution in a timely and effective manner, small specific surface area of original biochar, and low removal efficiency, etc. Achieve good application value, realize resource utilization, and shorten the effect of balancing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

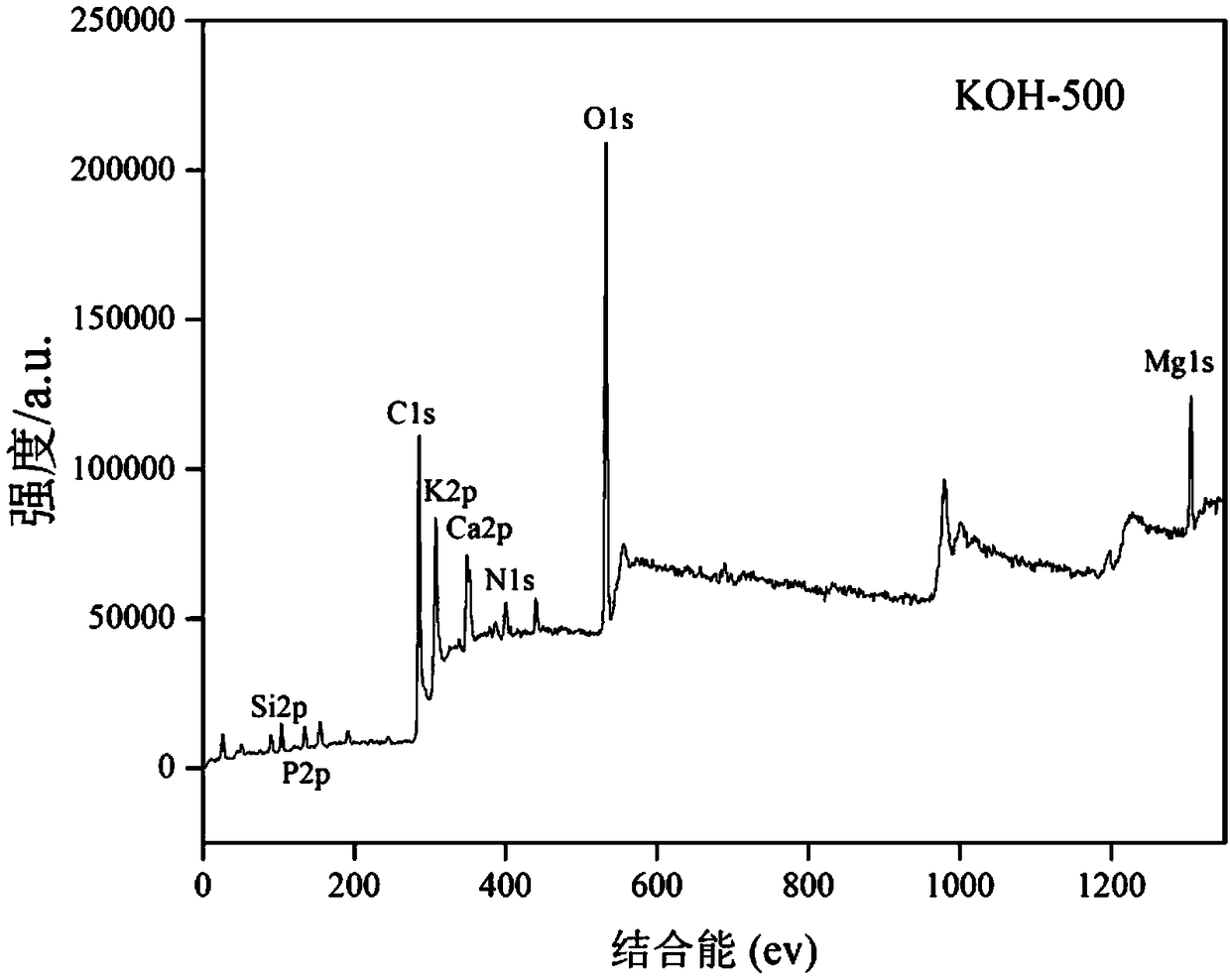

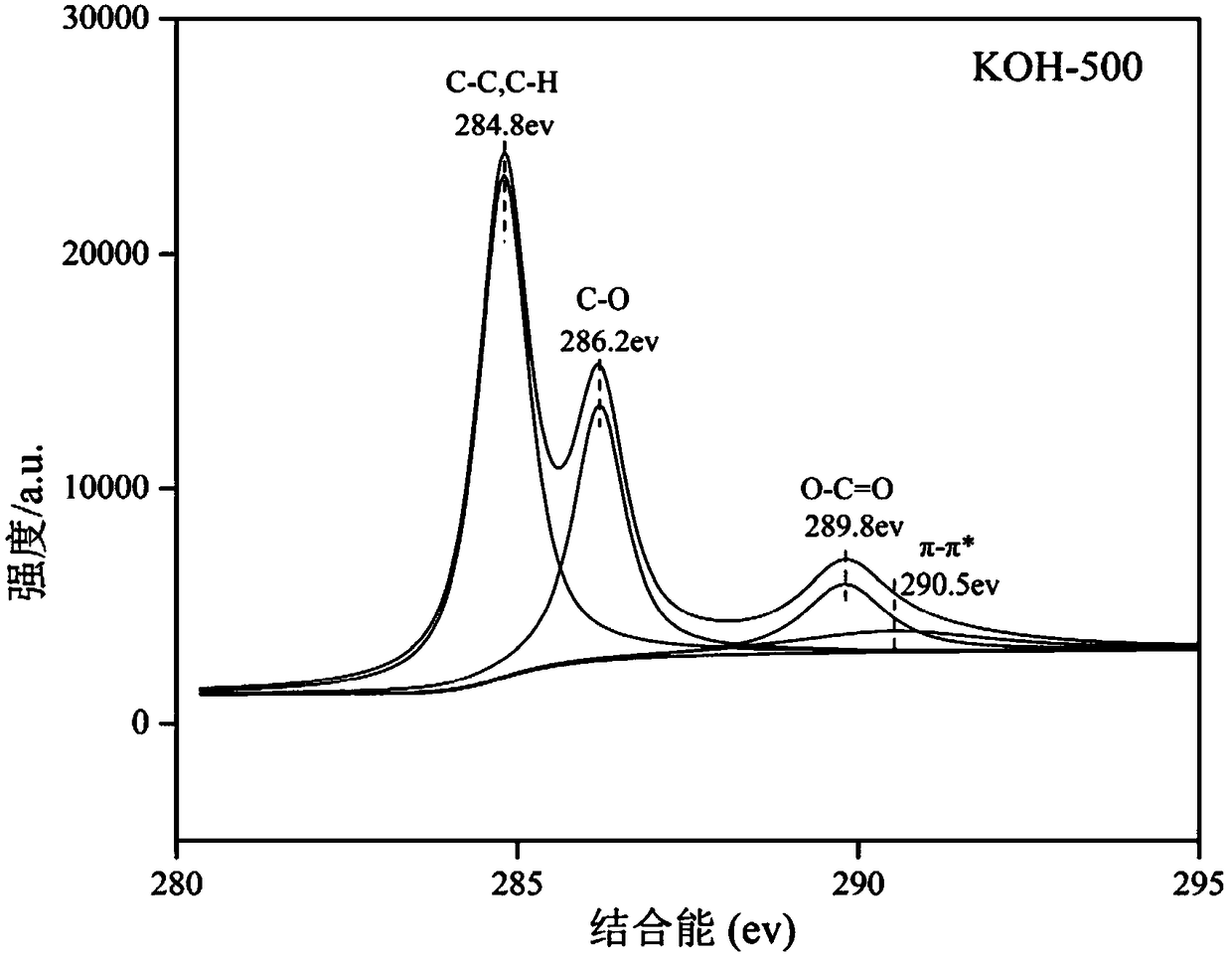

[0031] The alkali-modified pig manure biochar of the present invention is mainly prepared by pyrolysis of pig manure to obtain pig manure biochar, and the pig manure biochar is modified by potassium hydroxide solution.

[0032] A preparation method of the alkali-modified pig manure biochar of the present invention includes the following steps:

[0033] (1) Preparation of pig manure biochar: collect fresh pig manure, dry at 60°C to a moisture content of 10%-15%, crush, pass through a 100-mesh sieve, and store it in a sealed container for later use. Put the crushed and sieved pig manure into a tube furnace, blow in nitrogen, and pyrolyze at a high temperature, the heating rate is 8℃ / min, the pyrolysis temperature is 300℃, the pyrolysis residence time is 2h, and it is cooled to room temperature. Crush and pass a 100-mesh sieve to prepare pig manure biochar.

[0034] (2) Preparation of KOH solution: Weigh 5.61g KOH into a beaker, add an appropriate amount of ultrapure water to dissolve ...

Embodiment 2

[0038] A preparation method of the alkali-modified pig manure biochar of the present invention includes the following steps:

[0039] (1) Preparation of pig manure biochar: collect fresh pig manure, dry at 60°C to a moisture content of 10%-15%, crush, pass through a 100-mesh sieve, and store it in a sealed container for later use. Put the crushed and sieved pig manure into a tube furnace, blow in nitrogen, and pyrolyze at a high temperature. The heating rate is 8°C / min, the pyrolysis temperature is 500°C, and the pyrolysis residence time is 2h. Cool to room temperature and grind. Smash and pass a 100-mesh sieve to obtain pig manure biochar.

[0040] (2) Preparation of KOH solution: Weigh 5.61g KOH into a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 50mL volumetric flask, dilute to the mark with ultrapure water, shake well, and you will get 2.0mol / L KOH solution.

[0041] (3) Preparation of alkali-modified pig manure biochar: 5g biochar was adde...

Embodiment 3

[0045] A preparation method of the alkali-modified pig manure biochar of the present invention includes the following steps:

[0046] (1) Preparation of pig manure biochar: collect fresh pig manure, dry at 60°C to a moisture content of 10%-15%, crush, pass through a 100-mesh sieve, and store it in a sealed container for later use. Put the crushed and sieved pig manure into a tube furnace, blow in nitrogen, and pyrolyze at a high temperature. The heating rate is 8°C / min, the pyrolysis temperature is 700°C, the pyrolysis residence time is 2h, and it is cooled to room temperature. Crush and pass a 100-mesh sieve to prepare pig manure biochar.

[0047] (2) Preparation of KOH solution: Weigh 5.61g KOH into a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 50mL volumetric flask, dilute to the mark with ultrapure water, shake well, and you will get 2.0mol / L KOH solution.

[0048] (3) Preparation of alkali-modified biochar: Add 5g of biochar to 50mL of 2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com