Dual-ion battery and preparation method thereof

A dual-ion, battery technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of unsatisfactory chemical properties, degradation of aluminum anode cycle stability, low battery capacity, etc., and achieve excellent electrochemical stability. , capacity and cycle performance improvement, the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0105] As a preferred embodiment, the preparation method of dual-ion battery comprises the following steps:

[0106] a) Prepare the negative electrode: mix the active material of the negative electrode material, the conductive agent, the binder and the solvent to make a slurry; then coat the negative electrode material slurry on the surface of the negative electrode current collector, and cut it into pieces after drying to obtain the negative electrode of the required size ;

[0107] b) preparing electrolyte: dissolving lithium salt electrolyte in organic solvent and / or ionic liquid, stirring fully to obtain electrolyte;

[0108] c) Prepare the diaphragm: cut the diaphragm into the required size for later use;

[0109] d) Preparation of the positive electrode: mix the active material of the positive electrode material, the conductive agent, the binder and the solvent to form a slurry; then coat the positive electrode material slurry on the surface of the positive electrode cu...

Embodiment 1

[0116] This embodiment is a lithium double-ion battery, including a negative electrode, a separator, an electrolyte, and a positive electrode. Wherein, the specific material composition and preparation method of the dual-ion battery are as follows:

[0117] Step a) Prepare the negative electrode: add 0.7g of organic material pyrazine-quinoxaline copolymer, 0.2g of carbon nanotubes, and 0.1g of polytetrafluoroethylene into 2ml of nitrogen-methylpyrrolidone solution, grind thoroughly to obtain a uniform slurry; then The slurry was evenly coated on the surface of the copper foil (ie, the negative current collector) and dried in vacuum. Cut the electrode sheets obtained by drying into discs with a diameter of 12mm, and use them as positive electrodes after compaction;

[0118] Step b) preparing the diaphragm: cutting the glass fiber film into discs with a diameter of 16 mm as a diaphragm for subsequent use;

[0119] Step c) Preparation of electrolyte: Weigh 1.52g of lithium hexa...

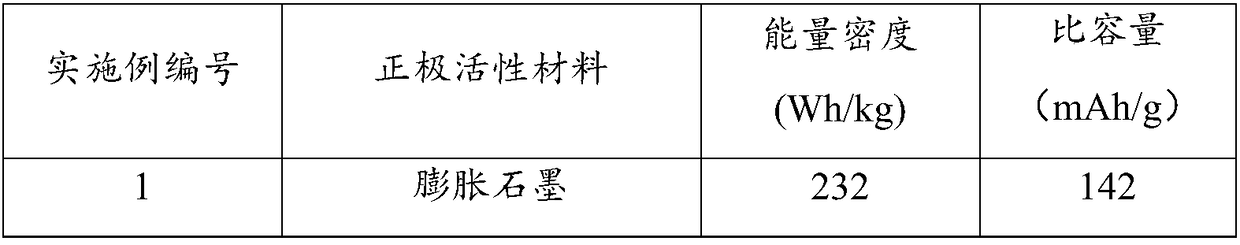

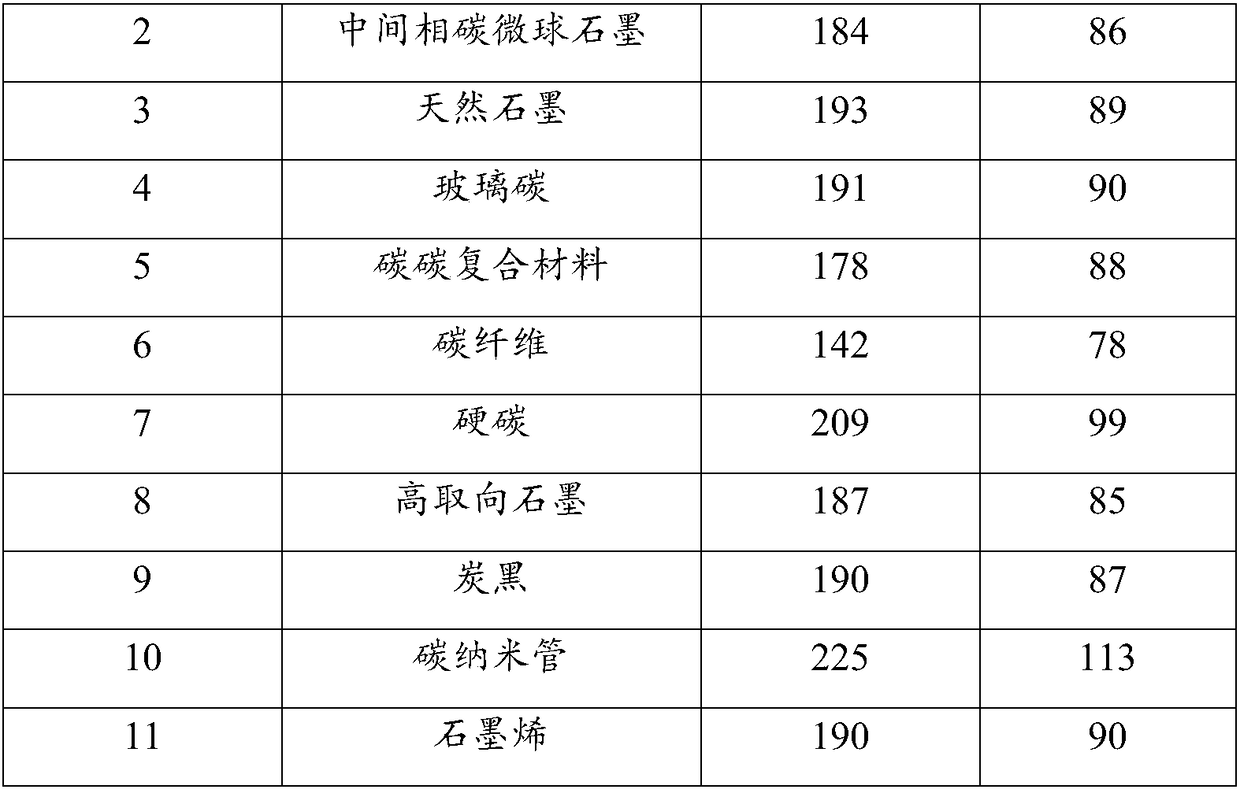

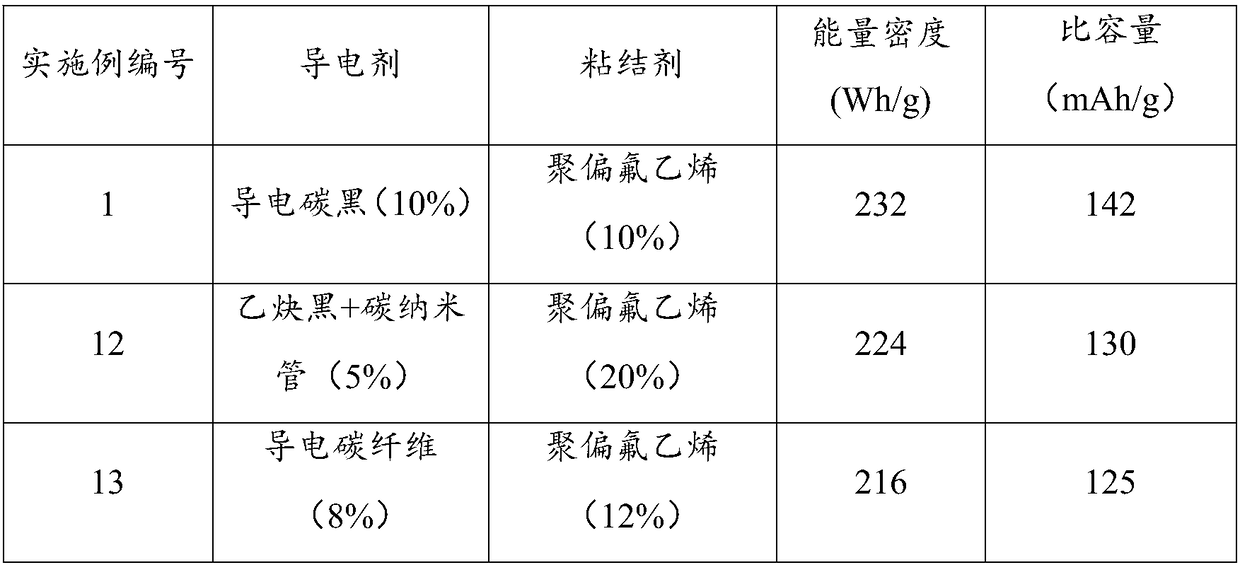

Embodiment 2-11

[0123] Examples 2-11 are a lithium double-ion battery, the difference from Example 1 is that the positive electrode active material used is different, and the rest are the same as Example 1. At the same time, performance tests were performed on the dual-ion batteries provided in Examples 1-11, and the specific material compositions and test results are listed in Table 1.

[0124] Battery performance tests include energy density and specific capacity tests, and the specific test methods are as follows:

[0125] Cycle charge and discharge: Cycle charge and discharge are carried out on the CT2001C-001 blue electric battery cycle test system, and the standard capacity of the electrode is tested by charging and discharging at a rate of 100mAh / g. The specific capacity of the material = current * time / sample mass, the energy density of the material = specific capacity of the material * plateau voltage of the battery.

[0126] The performance test result of the double-ion battery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com