Method for manufacturing piezoelectric flexible sensor

A flexible sensor, piezoelectric technology, applied in pressure sensors, sensors, medical science and other directions, can solve the problems of complex preparation process, complex signal components, easy to be interfered by noise, etc., achieve scientific and reasonable preparation process, simplify preparation process, application Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

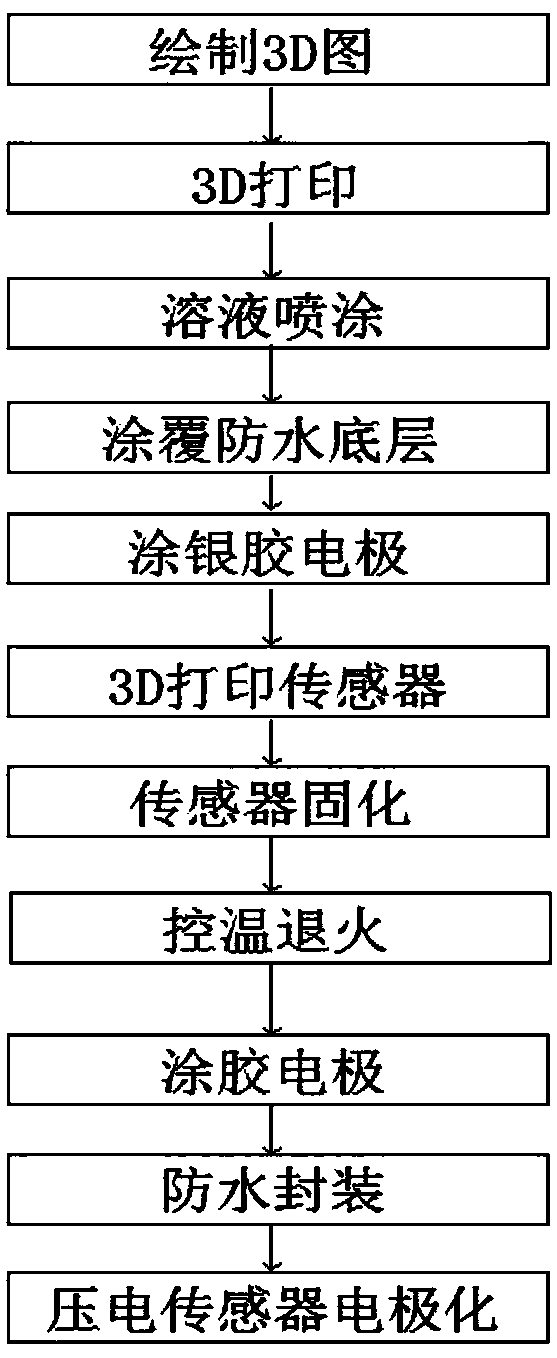

[0035] The preparation method of the piezoelectric flexible sensor 1 involved in this embodiment, its basic process includes the following steps:

[0036] (1) Draw 3D maps: MRI imaging of the muscles of the residual limbs, according to the MRI structure, refer to the standard human anatomical muscle tissue map (such as ZygoteBody (https: / / www.zygotebody.com)), draw the 3D of the corresponding muscles picture;

[0037] (2) 3D printing: Input the muscle 3D model into the 3D printer, and use polylactic acid PLA raw material to 3D print the corresponding muscle model. The printing temperature is controlled between 190 degrees and the heating temperature of the bottom plate is controlled between 60 degrees. According to the standard fusion deposition (FDM) 3D printer process, using the usual filamentary materials to print; smooth the surface of the printed model: in a well-ventilated area, wear non-latex (nitrile or neoprene) gloves to place the model on the bottom In a sealed con...

Embodiment 2

[0051] This embodiment further explains the process of 3D printing piezoelectric flexible sensor 1: general 3D printing uses wax, powder, filamentous metal or plastic raw materials, and this embodiment uses liquid solution slurry for 3D printing process; The 3D printing process of this embodiment adopts the printing structure of the mobile bottom plate and the stepping motor drive for a large distance, and realizes the fine structure printing by adjusting the moving scanning speed and controlling the viscosity and temperature of the slurry, combined with the smallest nozzle of the precision micro-injection pump ;The print head part includes a micro-motor-controlled needle valve nozzle and a stainless steel barrel, the sliding upper end of the stainless steel barrel can be equipped with a chemically inert Teflon piston print push rod, and the edge of the Teflon piston is sealed with the stainless steel barrel. The head part also includes heating components and nozzle temperature...

Embodiment 3

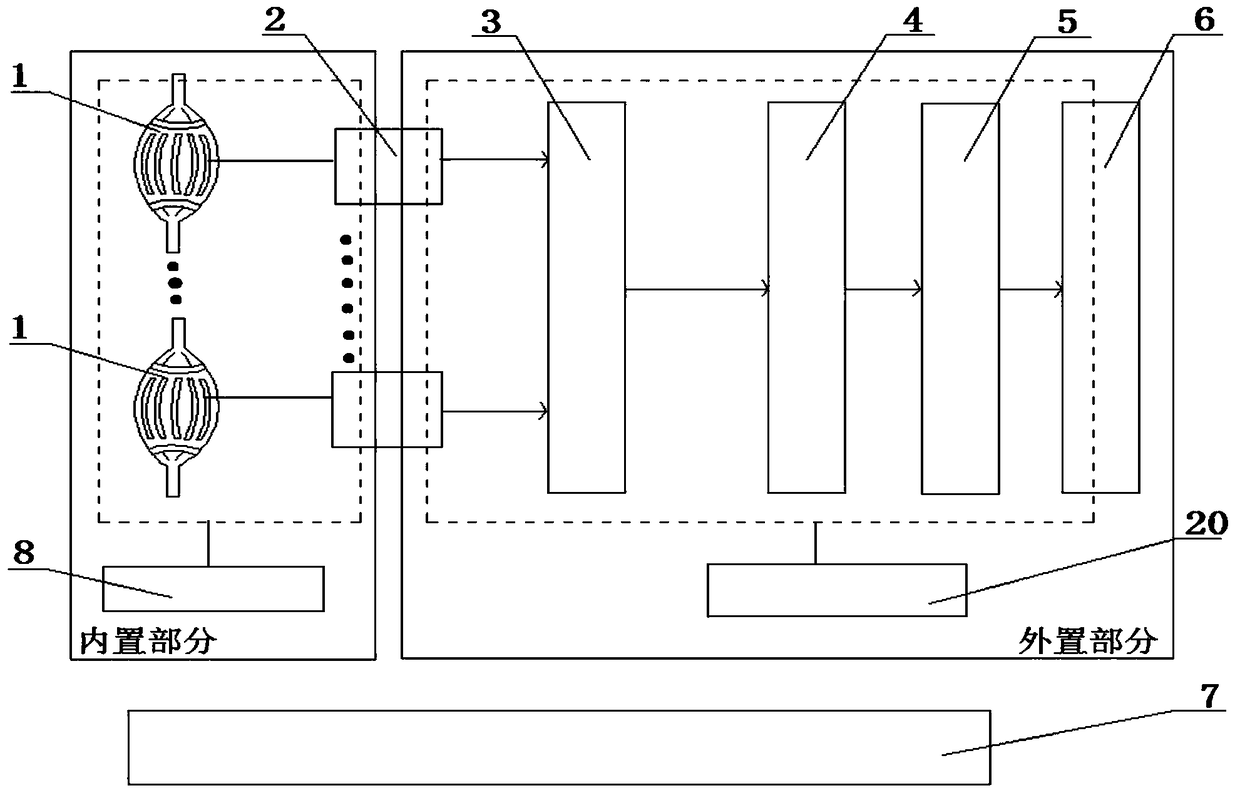

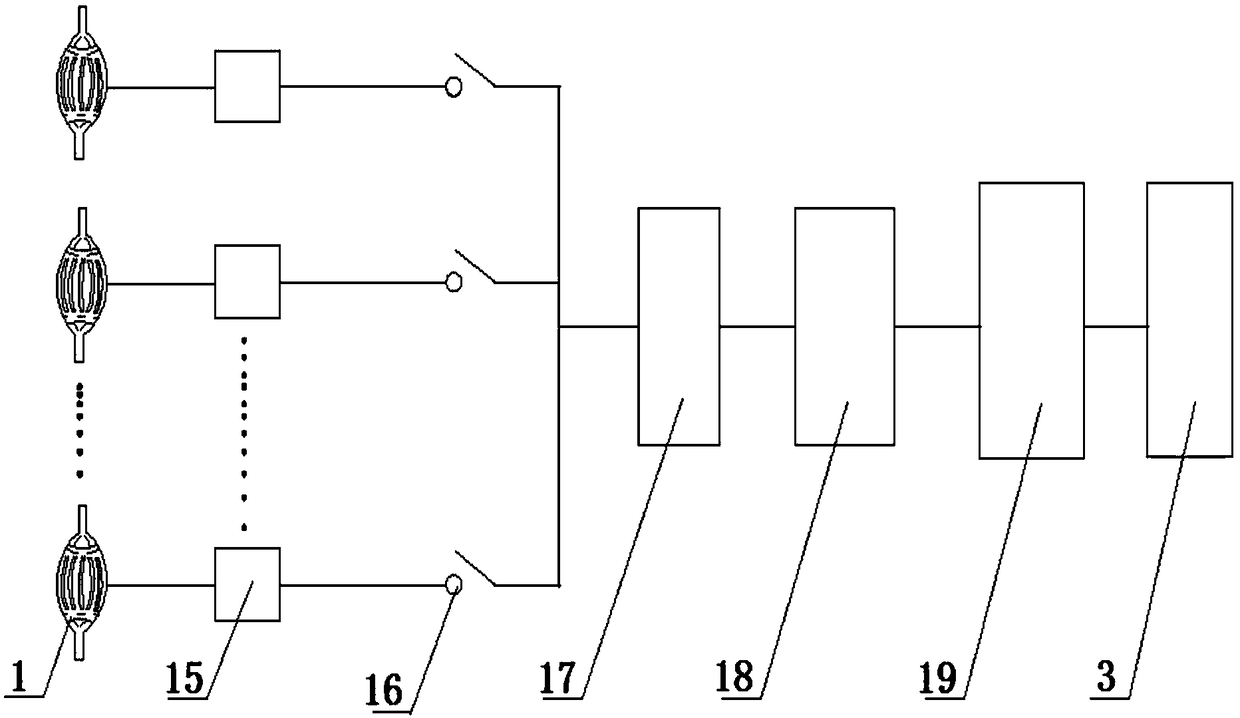

[0053] The piezoelectric flexible sensing device involved in this embodiment is as figure 2 As shown, its main structure includes a piezoelectric flexible sensor 1, an EMG signal pre-processing module 2, a Bluetooth wireless transmitting module 3, a Bluetooth wireless receiving module 4, an EMG signal analysis and processing module 5, a prosthetic control module 6, and a charging module 7 , built-in circuit power supply module 8, electrode 9, muscle tissue 10, suture thread 11, preamplifier 15, multi-channel analog switch 16, filter 17 for removing noise interference, post-stage amplifier 18, single-chip microcomputer analog-to-digital conversion unit 19 and prosthesis The power module 20; the piezoelectric flexible sensor device includes a built-in part and an external part, the built-in part is installed on the surface of the residual limb muscle, and the external part is installed in the prosthesis; wherein the piezoelectric flexible sensor 1 of the built-in part is fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com