A high-loading multi-effect filter material and its preparation method

A high-load, filter material technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of poor fiber spinnability, easy to generate static electricity, low fiber strength, etc., to enhance fiber spinnability, reaction Sufficient and enhanced conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

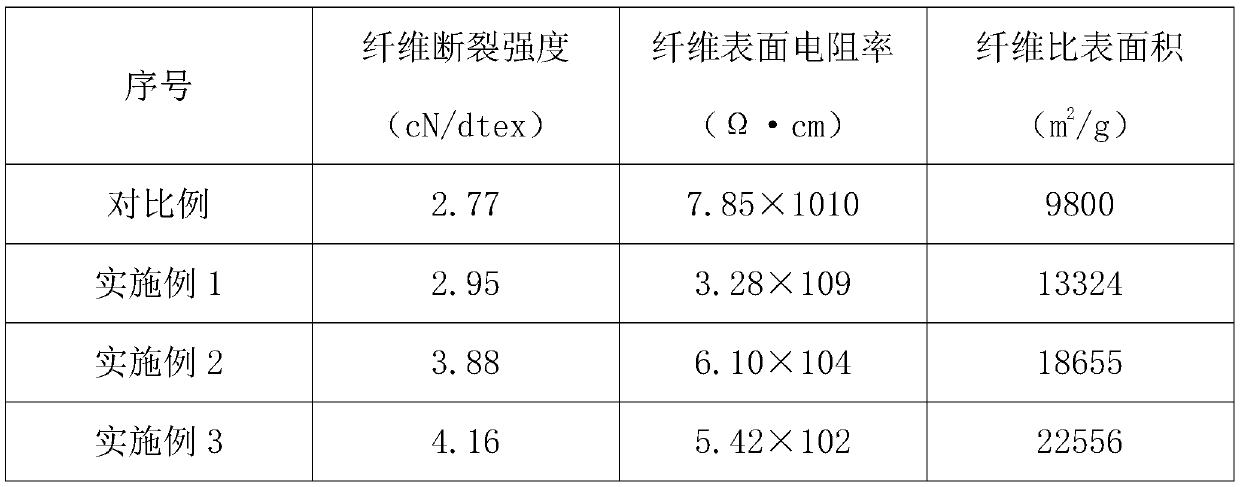

Examples

Embodiment 1

[0036] 1) Pretreatment of polytetrafluoroethylene resin: store the polytetrafluoroethylene resin in a storage room with a temperature of 16°C for more than 5 days; take the static polytetrafluoroethylene resin and pass it through a 10-mesh sieve;

[0037] 2) Add graphene powder during the mixing and stirring process of polytetrafluoroethylene resin, graphene powder, aviation kerosene, and polytetrafluoroethylene resin are added according to the mass ratio of 0.5:20:100, and graphene is obtained through the membrane splitting process route / PTFE composite fiber;

[0038] Wherein, the process steps of membrane splitting method are:

[0039] a. Stir the mixture and send it to the drying room to stand for 60 hours. The temperature of the drying room is 60°C. After standing, it is pre-pressed and formed. The stirring speed is 10r / min. The stirring method is 20 minutes forward and 30 minutes reversed; The formed molding material is pushed and pressed to form a columnar molding mate...

Embodiment 2

[0046] 1) Pretreatment of polytetrafluoroethylene resin: store the polytetrafluoroethylene resin in a storage room with a temperature of 16°C for more than 5 days; take the static polytetrafluoroethylene resin and pass it through a 10-mesh sieve;

[0047] 2) Add graphene powder during the mixing and stirring process of polytetrafluoroethylene resin, graphene powder, aviation kerosene, and polytetrafluoroethylene resin are added in a mass ratio of 5:30:100, and graphene is obtained through the membrane splitting process route / PTFE composite fiber;

[0048] Wherein, the process steps of membrane splitting method are:

[0049] a. Stir the mixture and send it to the drying room to stand for 60 hours. The temperature of the drying room is 60°C. After standing, it is pre-pressed and formed. The stirring speed is 10r / min. The stirring method is 20 minutes forward and 30 minutes reversed; The formed molding material is pushed and pressed to form a columnar molding material;

[0050...

Embodiment 3

[0056] 1) Pretreatment of polytetrafluoroethylene resin: store the polytetrafluoroethylene resin in a storage room with a temperature of 16°C for more than 5 days; take the static polytetrafluoroethylene resin and pass it through a 10-mesh sieve;

[0057] 2) Add graphene powder during the mixing and stirring process of polytetrafluoroethylene resin, graphene powder, aviation kerosene, and polytetrafluoroethylene resin are added in a mass ratio of 10:40:100, and graphene is obtained through the process route of membrane splitting method / PTFE composite fiber;

[0058] Wherein, the process steps of membrane splitting method are:

[0059] a. Stir the mixture and send it to the drying room to stand for 60 hours. The temperature of the drying room is 60°C. After standing, it is pre-pressed and formed. The stirring speed is 10r / min. The stirring method is 20 minutes forward and 30 minutes reversed; The formed molding material is pushed and pressed to form a columnar molding materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com