Ethane, propane selective oxidation catalyst high in activity, and preparation method and applications thereof

A technology for selective oxidation and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, hydrocarbon oxidation to prepare oxygen-containing compounds, physical/chemical process catalysts, etc. Limitation and other problems, to achieve the effect of short preparation cycle, inhibited enrichment, and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a metal vanadium framework doped mesoporous nano-SiO 2 Particle catalyst in which the molar ratio of V:Si is 0.01:100 V-SiO 2 The catalyst is obtained by the following preparation steps:

[0054] (1) Weigh the corresponding mass of NH 4 VO 4 Add 25mL deionized water, heat and dissolve in a 35°C water bath to form a uniform phase A;

[0055] (2) Weigh 0.5g of CTAB and dissolve it in 45mL of deionized water, add 15mL of ethanol and stir until completely dissolved to obtain solution B;

[0056] (3) Use a pipette to take 15mL of diethyl ether and drop 0.8mL of ammonia water into solution B, stir for 20 minutes, add uniform solution A, and stir for 5 minutes;

[0057] (4) Take 2.5mL TEOS and quickly drop them into the mixed solution of A and B and stir vigorously for 4h. The white precipitate is obtained by filtering (water pump decompression system), washing with water and alcohol several times, and drying in air at 60°C for 24h. The obtained w...

Embodiment 2

[0062] This embodiment provides a metal vanadium framework doped mesoporous nano-SiO 2 Particle catalysts in which the V:Si molar ratio is 2:100 V-SiO 2 The preparation steps of the catalyst are the same as in Example 1, the difference is only in the doping amount of metal vanadium.

[0063] The method for catalyzing the selective oxidation reaction of propane adopted by the catalyst, and the detection and analysis method of reactants are all the same as those in Example 1. The activity evaluation results and main product selectivity are shown in Table 2.

[0064] Table 2 Selective distribution of main products in propane selective oxidation reaction

[0065]

Embodiment 3

[0067] This embodiment provides a metal vanadium framework doped mesoporous nano-SiO 2 Particle catalysts in which the V:Si molar ratio is 1.5:100 V-SiO 2 The preparation steps of the catalyst are the same as in Example 1, the difference is only in the doping amount of metal vanadium.

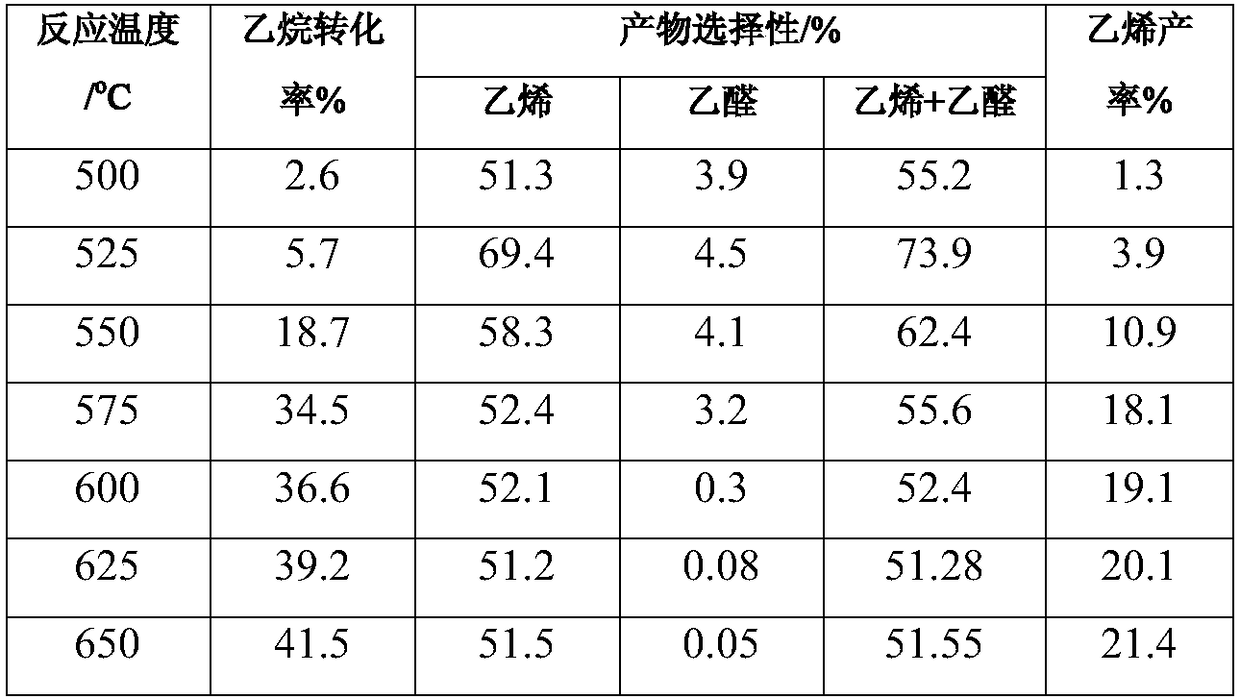

[0068] The above-mentioned catalysts were evaluated for ethane selective oxidation performance: the ethane selective oxidation reaction was carried out on a miniature fixed-bed reactor, and the gas composition after the reaction was analyzed on-line by a gas chromatograph (7890). The loading amount of catalyst is 0.3g, feeds carrier gas nitrogen and regulates the total flow of carrier gas to be 30mL / min, wherein C 2 h 6 :O 2 :N 2 =2:1:12. After continuing to feed the carrier gas for 30 min, start heating the reaction tube, and then feed ethane with a purity of 99.999%. Subsequently, the reaction temperature was gradually increased, and the reaction products were analyzed. The reaction te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com