Method for preparing fertility-increasing and detoxifying type acidic soil conditioner

An acid soil and improver technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of acid soil aluminum toxicity and low soil fertility, increase agricultural production costs, consume mineral resources, etc. Base ion retention ability, high content of ashing alkali, effect of improving acid soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

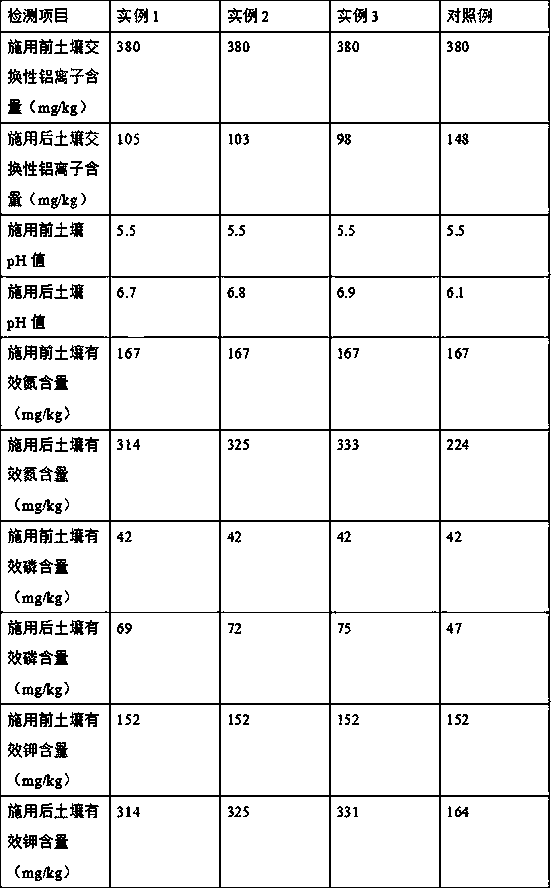

example 1

[0025] According to the mass ratio of 2:1:3, pig manure, fungus chaff and water were mixed to obtain a mixed slurry, and the mixed slurry was spread on a stainless steel tray, and then the tray was placed at a temperature of 35°C and a relative air humidity of In a greenhouse at 70°C, let it stand for 9 days to mold naturally to obtain moldy products; put the moldy products into a carbonization furnace, then pass argon into the carbonization furnace until all the air is replaced, heat up to 400°C, and keep warm for 2 hours for carbonization , to obtain biochar, biochar is put into pulverizer and pulverized for 40min and crosses 50 mesh sieves, and the sieve is collected to be biochar particles; the biochar particles and mass fraction are 90% sulfuric acid solution in a mass ratio of 1: 5 After mixing, stir and react at 0°C for 10 minutes to obtain the reactant, mix the reactant with sodium nitrate and potassium permanganate at a mass ratio of 200:3:20, stir and react at 30°C fo...

example 2

[0027]According to the mass ratio of 2:1:3, pig manure, fungus chaff and water were mixed to obtain a mixed slurry, and the mixed slurry was spread on a stainless steel tray, and then the tray was placed at a temperature of 40°C, and the relative humidity of the air was In the greenhouse at 75°C, let it stand for 9 days to get moldy products; put the moldy products into the carbonization furnace, then pass argon into the carbonization furnace until all the air is replaced, heat up to 450°C, and keep warm for 2 hours. , to obtain biochar, biochar is put into pulverizer and pulverized for 45min and crosses 50 mesh sieves, and the collected sieve is biochar particles; the biochar particles and mass fraction are 90% sulfuric acid solution in mass ratio of 1: 5 After mixing, stir and react at 0°C for 13 minutes to obtain the reactant, mix the reactant with sodium nitrate and potassium permanganate at a mass ratio of 200:3:20, stir and react at 33°C for 35 minutes, then heat up to 85...

example 3

[0029] According to the mass ratio of 2:1:3, pig manure, fungus chaff and water were mixed to obtain a mixed slurry, and the mixed slurry was spread on a stainless steel tray, and then the tray was placed at a temperature of 45°C and a relative air humidity of In a greenhouse at 80°C, let it stand for 10 days to mold naturally to obtain a moldy product; put the moldy product into a carbonization furnace, then pass argon into the carbonization furnace until all the air is replaced, heat up to 500°C, and keep warm for 3 hours for carbonization , obtain biochar, put biochar into pulverizer and cross 50 mesh sieves after pulverizing for 50min, collect the sieved thing and be biochar particles; the sulfuric acid solution that biochar particles and mass fraction are 90% is 1 by mass ratio: 5 After mixing, stir and react at 1°C for 15min to obtain the reactant, mix the reactant with sodium nitrate and potassium permanganate in a mass ratio of 200:3:20, stir and react at 35°C for 40min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com