A kind of preparation method of foamed magnesium sandwich panel

A sandwich panel and foamed magnesium technology, which is applied in chemical instruments and methods, metal rolling, lamination auxiliary operations, etc., can solve the problem that the thickness and core layer structure of the foamed aluminum sandwich panel are not easy to control, the production equipment is complicated, and the blank is lost. It can reduce the free boundary, reduce the manufacturing cost and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

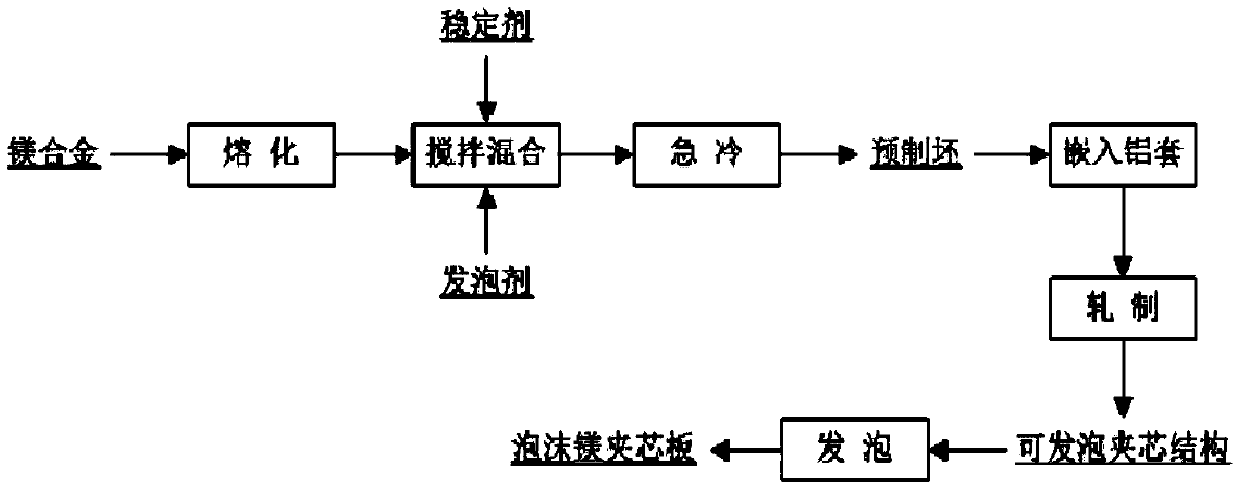

[0033] A kind of preparation method of foamed magnesium sandwich panel, carries out according to the following steps:

[0034] (1) With Al accounting for 8% by mass of the magnesium alloy used, and Ca accounting for 5% of the magnesium alloy by mass of the magnesium-aluminum-calcium ternary alloy as the substrate, it was melted at 750° C. and kept for 10 minutes to form a magnesium alloy melt body.

[0035] (2) Lower the temperature of the above-mentioned magnesium alloy melt to 600°C, first add the stabilizer silicon carbide powder to it, then add the foaming agent magnesium carbonate, and stir evenly, the stirring speed is 500r / min, and the stirring time is 5min, then The uniformly stirred magnesium alloy melt was rapidly cooled at a rate of 30° C. / s for 5 minutes to obtain a foamable preform. The stabilizer silicon carbide powder and the blowing agent magnesium carbonate need to be preheated at 400°C for 4 hours before adding to the magnesium melt. The silicon carbide powd...

Embodiment 2

[0039] A kind of preparation method of foamed magnesium sandwich panel, carries out according to the following steps:

[0040] (1) With Al accounting for 14% by mass percentage of the magnesium alloy used, and Ca accounting for 1% of the magnesium alloy by mass, the magnesium-aluminum-calcium ternary alloy is used as a substrate, melted at 700 ° C and kept for 20 minutes to form a magnesium alloy melt body.

[0041](2) The temperature of the above-mentioned magnesium alloy melt is lowered to 580°C, and uniformly mixed stabilizer alumina powder and foaming agent calcium carbonate are added thereto, and stirred evenly, the stirring speed is 2500r / min, and the stirring time is 2min, after that The uniformly stirred magnesium alloy melt was rapidly cooled at a rate of 15° C. / s for 10 minutes to obtain a foamable preform. The stabilizer alumina powder and the foaming agent titanium hydride need to be preheated at 450°C for 2 hours before adding to the magnesium melt. The alumina p...

Embodiment 3

[0045] A kind of preparation method of foamed magnesium sandwich panel, carries out according to the following steps:

[0046] (1) With Al accounting for 11% by mass percentage of the magnesium alloy used, Ca accounting for the magnesium aluminum calcium ternary alloy of 3% by mass percentage of the magnesium alloy used as the matrix, melting at 710 ° C and keeping it warm for 15 minutes to form a magnesium alloy melt body.

[0047] (2) Lower the temperature of the above-mentioned magnesium alloy melt to 585°C, first add foaming agent magnesium carbonate to it, and stir evenly, the stirring speed is 1500r / min, and the stirring time is 3min, and then the evenly stirred magnesium alloy melt Rapidly cool at a rate of 20°C / s for 8 minutes to obtain a foamable preform. The foaming agent magnesium carbonate needs to be preheated at 420°C for 3 hours before being added to the magnesium melt, and the amount of magnesium carbonate added is 5% of the mass percentage of the magnesium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com