High-specific capacitance low-impedance graphene/carbon nanotube composite material preparation method

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of high specific capacitance and low impedance graphene/carbon nanotube composite materials, which can solve the problems of low synthesis yield, complicated process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of high specific capacitance and low impedance graphene / carbon nanotube composite material, comprising the steps of:

[0033] (1) Dissolve 0.03g graphene oxide in 18mL distilled water and sonicate for 30min to form a brown-yellow suspension;

[0034] (2) Use 5% sodium carbonate to adjust the pH of the suspension to 9-10, add sodium borohydride, sonicate for 10 minutes, stir magnetically at 80°C for 2 hours, and the mass ratio of graphene oxide to sodium borohydride is 1:8;

[0035] (3) Mix 75mL of concentrated sulfuric acid and 25mL of concentrated nitric acid; dissolve 0.2g of carbon nanotubes in the above mixed acid, ultrasonicate for 30min, filter, wash, freeze-dry, and fully grind for later use; weigh 0.004g of acidified carbon nanotubes Dissolve in 42mL distilled water and sonicate for 20min;

[0036] (4) Mix the material obtained in step (2) with the material obtained in step (3) and disperse uniformly by ultrasonic for 5 minutes, put it into...

Embodiment 2

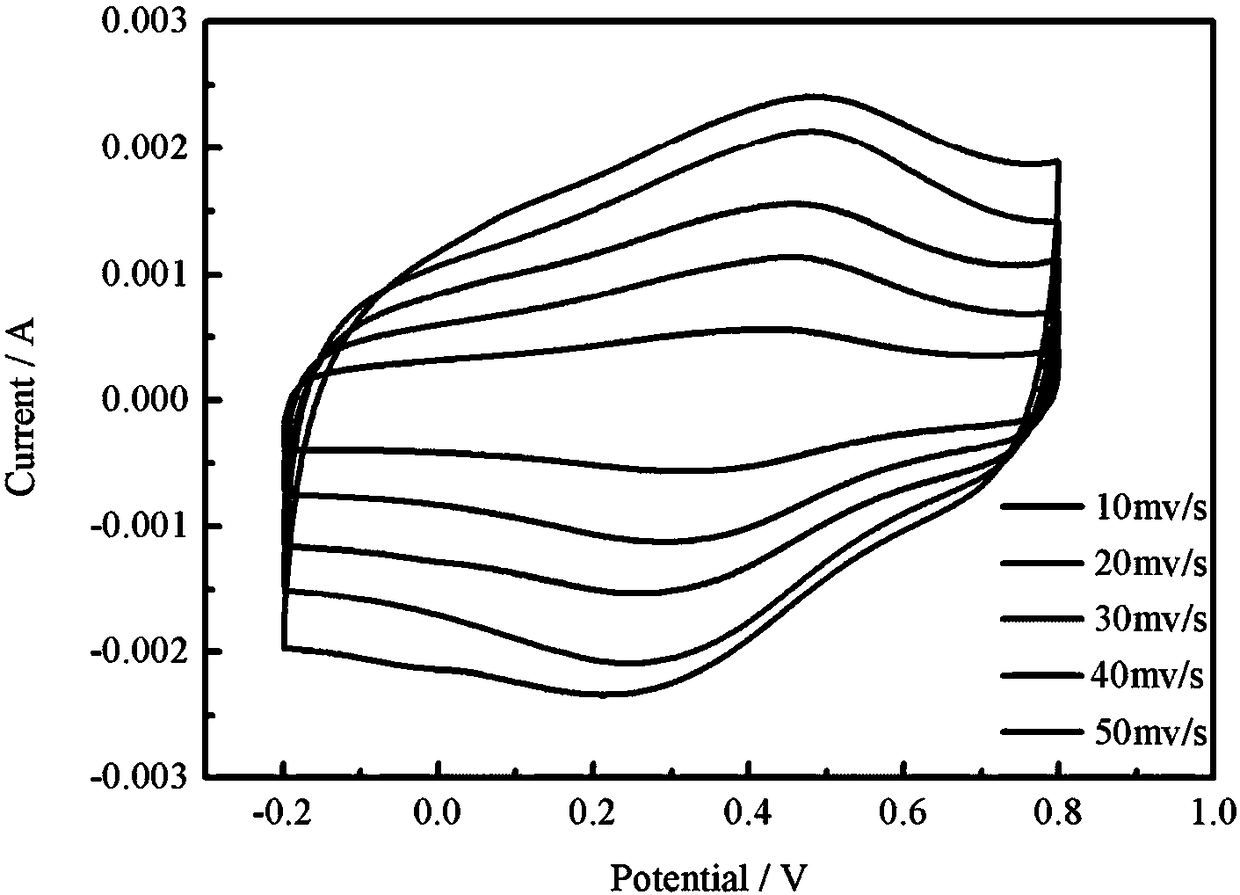

[0041] The difference between this example and Example 1 is that the volume of the solvent for the hydrothermal reaction is changed to 50mL, and other conditions remain unchanged to obtain a graphene / carbon nanotube composite material. Please see Figure 5 , Test the specific capacitance of the present embodiment sample with electrochemical workstation (CHI660E), as shown in the figure, calculate with formula Cm=I Δt / m Δv, specific capacitance is 305F / g when 0.5A / g. Under the same current density, compared with the specific capacitance in Example 1, the analysis reason may be that an appropriate increase in the amount of solvent helps the uniform dispersion of graphene and carbon nanotubes, thereby improving the specific capacitance of the material.

Embodiment 3

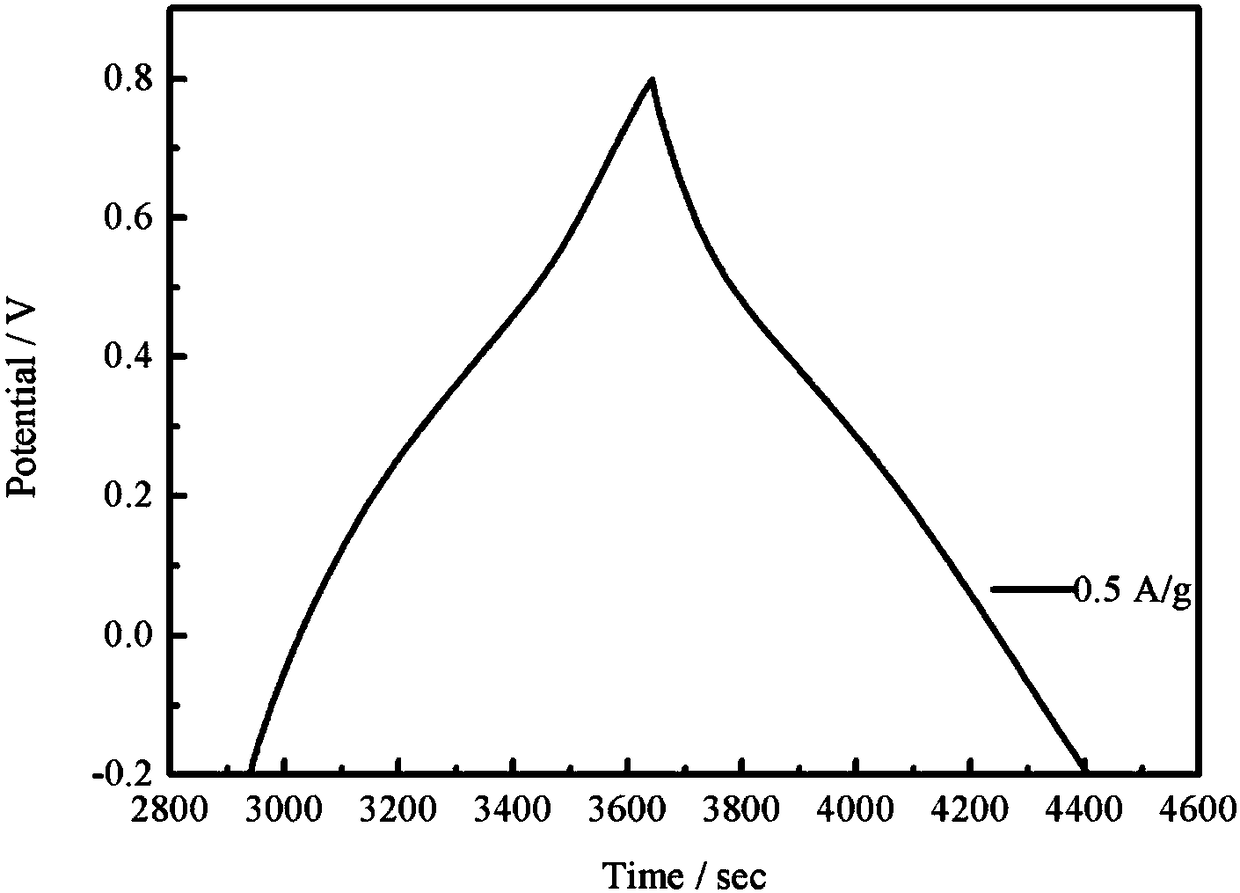

[0043] The difference between this example and Example 1 is that the graphene / carbon nanotube composite material is obtained by changing the reduction temperature of graphene oxide in step (2) to 70° C. and keeping other conditions unchanged. Please see Image 6 , with the electrochemical workstation (CHI660E) to test the specific capacitance of the sample of this embodiment, as shown in the figure, calculated with the formula Cm=I Δt / m.Δv, the specific capacitance is 233.07F / g at 0.5A / g . Under the same current density, compared with the specific capacitance in Example 1, the analysis reason may be that the conductivity of graphene oxide is poor, and the conditions in Example 1 are more conducive to the reduction of graphene oxide, thereby improving the composite material. specific capacitance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com