Seaweed meal with adhesive effect for aquatic feed

An aquatic feed and bonding technology, which is applied in the field of seaweed powder for feed and seaweed powder for aquatic feed, to achieve the effects of reducing powder extraction rate, reducing environmental pollution and preventing diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

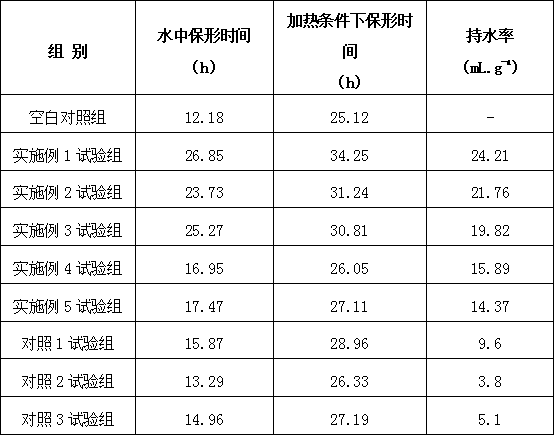

Examples

Embodiment 1

[0024] A kind of seaweed powder for aquafeed with binding effect is prepared through the following steps:

[0025] (1) Ingredients: Accurately weigh seaweed raw materials according to the ratio of 10 parts of Enteromorpha, 5 parts of Ulva, 30 parts of Kelp, 20 parts of Wakame, 7 parts of Sargassum, 10 parts of Laver, and 18 parts of Gracilaria;

[0026] (2) Mixing and beating: After mixing the weighed seaweed, add 2 times the volume ratio of purified water, and then grind and beat the seaweed mixture;

[0027] (3) Compound enzymatic hydrolysis: add cellulase, pectinase and compound protease to the seaweed slurry, the addition amount is 2.5%, 3% and 3% of the mass ratio of the seaweed pulp respectively, and enzymatically hydrolyze at 30-50°C for 3 hours; After enzymatic hydrolysis, the carrier is added in a proportion of 20% of the seaweed mass, and the carrier is kelp residue or Gracilaria residue;

[0028] (4) Drying and crushing: the seaweed slurry is dried at 40-70°C and c...

Embodiment 2

[0030] A kind of seaweed powder for aquafeed with binding effect is prepared through the following steps:

[0031] (1) Ingredients: Accurately weigh seaweed raw materials according to the ratio of 12 parts of Enteromorpha, 3 parts of Ulva, 35 parts of Kelp, 15 parts of Wakame, 12 parts of Sargassum, 5 parts of Laver, and 18 parts of Gracilaria;

[0032] (2) Mixing and beating: After mixing the weighed seaweed, add 3 times the volume ratio of pure water, and then grind and beat the seaweed mixture;

[0033] (3) Compound enzymatic hydrolysis: add cellulase, pectinase and compound protease to the seaweed slurry, the addition amount is 5%, 4%, 5% of the mass ratio of the seaweed slurry, and enzymolyze at 30-50°C for 2 hours; After enzymatic hydrolysis, the carrier is added at a ratio of 30% of the seaweed mass, and the carrier is kelp residue or Gracilaria residue;

[0034] (4) Drying and crushing: the seaweed slurry is dried at 40-70°C and crushed to 30-60 mesh to obtain seaweed...

Embodiment 3

[0036] A kind of seaweed powder for aquafeed with binding effect is prepared through the following steps:

[0037] (1) Ingredients: Accurately weigh seaweed raw materials according to the ratio of 8 parts of Enteromorpha, 8 parts of Ulva, 25 parts of Kelp, 25 parts of Wakame, 5 parts of Sargassum, 14 parts of Laver, and 15 parts of Gracilaria;

[0038](2) Mixing and beating: mix the weighed seaweed, add 1 times the volume ratio of pure water, and then grind the seaweed mixture for beating;

[0039] (3) Compound enzymatic hydrolysis: add cellulase, pectinase and compound protease to the seaweed slurry, the addition amount is 2%, 2% and 1% of the mass ratio of the seaweed slurry, and enzymolyze at 30-50°C for 4 hours; After enzymatic hydrolysis, the carrier is added in a proportion of 10% of the seaweed mass, and the carrier is kelp residue or Gracilaria residue;

[0040] (4) Drying and crushing: the seaweed slurry is dried at 40-70°C and crushed to 30-60 mesh to obtain seaweed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com