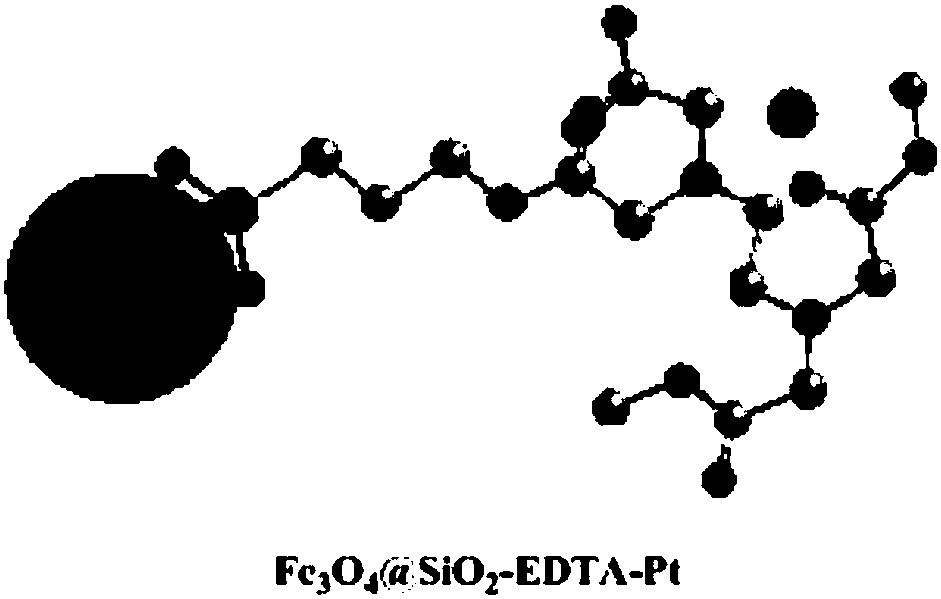

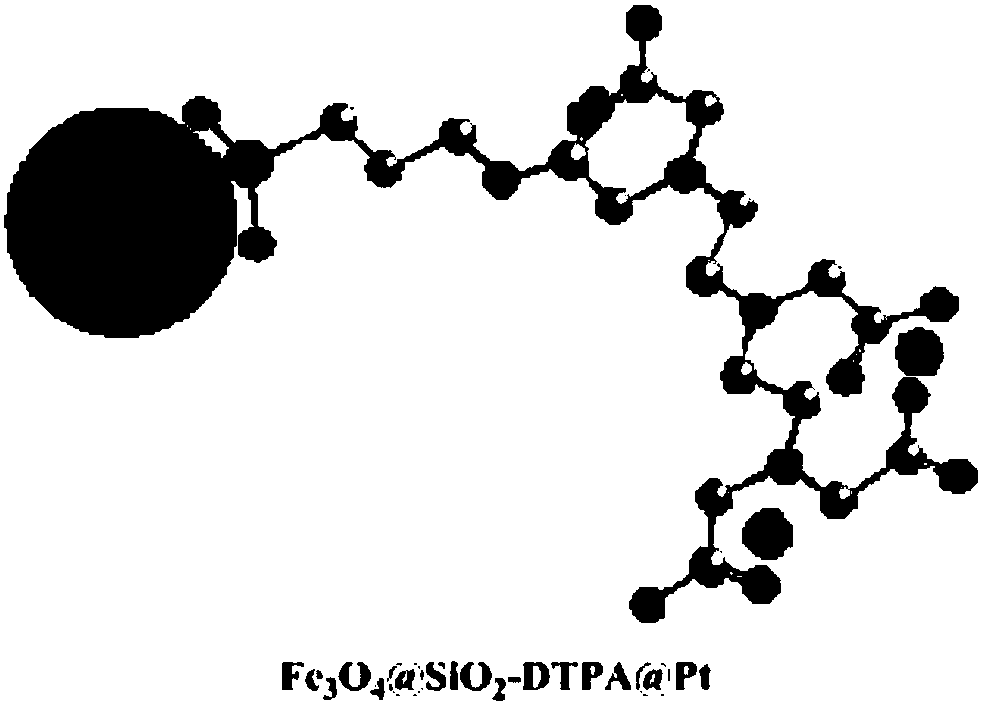

Polycarboxyl magnetic silicon nanosphere immobilized platinum catalyst as well as preparation method and application thereof

A magnetic nano-platinum catalyst technology, applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive metal platinum, low catalytic activity, and many by-products, and achieve enhanced catalytic efficiency , excellent catalytic activity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

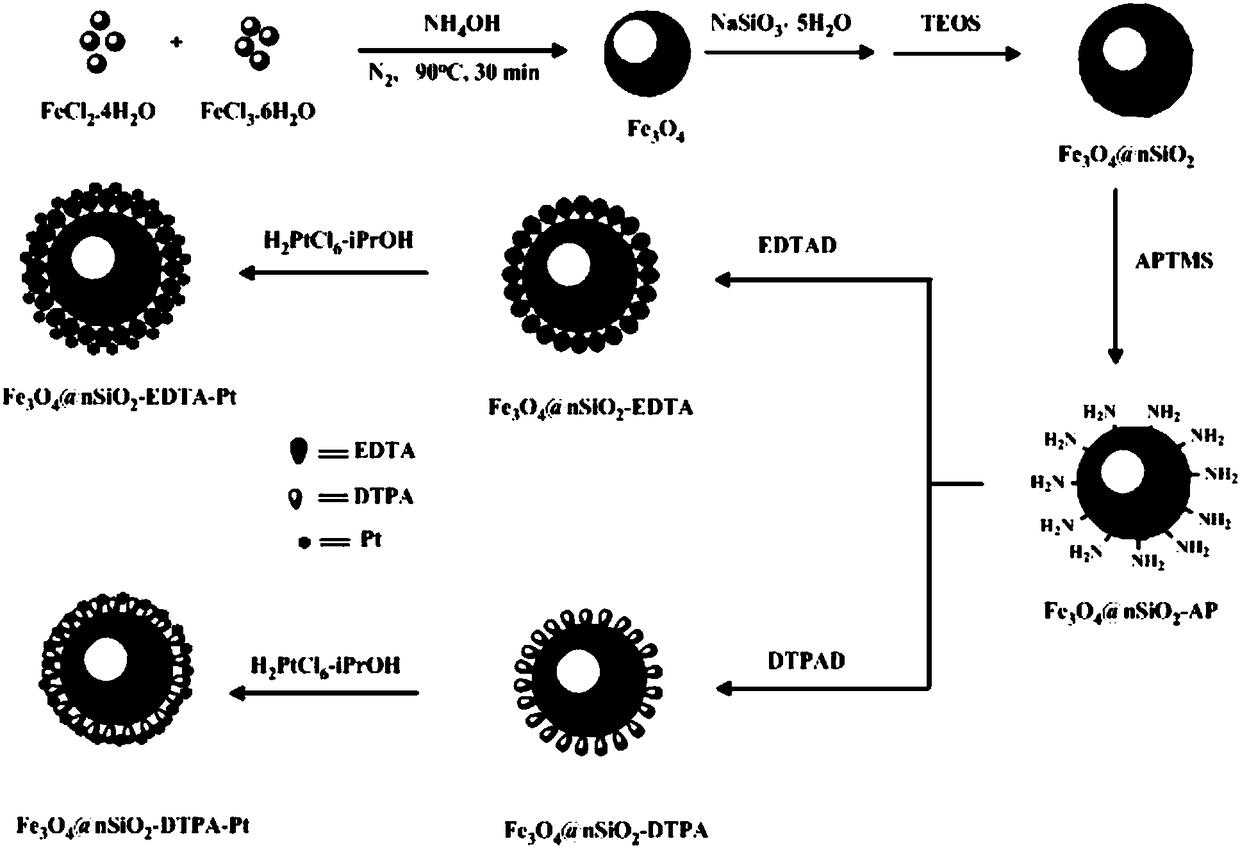

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of ethylenediaminetetraacetic dianhydride (EDTA dianhydride, EDTAD):

[0072] Weigh 20g of ethylenediaminetetraacetic acid (EDTA) in a 100mL three-necked flask, and add 34mL of pyridine and 26mL of acetic anhydride to the three-necked flask successively (the molar ratio of ethylenediaminetetraacetic acid, pyridine, and acetic anhydride is 1:1:1.2 ), mechanically stirred and refluxed at 65°C for 24 hours; after the reaction was completed, the solid product was obtained by suction filtration, and the solid product was washed and dried with anhydrous ether to obtain the crude EDTAD; the crude EDTAD was placed in a 100mL conical flask, and 55mL of Acetic anhydride (the weight ratio of acetic anhydride to EDTAD crude product is 3:1), stirring intermittently for 30min, after suction filtration, washing with acetic anhydride and anhydrous ether successively, suction filtration, vacuum drying at 65°C to obtain the EDTAD product and place it in a dry place spare ...

Embodiment 2

[0084] Adopt the method of embodiment 1 to carry out catalyst preparation multi-carboxyl magnetic nano-silicon sphere immobilized platinum catalyst, and its difference only is that the anhydrous solvent that adds in the nano-ferric oxide magnetic silicon sphere in step (4) is cyclohexane.

Embodiment 3

[0086] Adopt embodiment 1 method to carry out catalyzer preparation multi-carboxyl magnetic nano-silica sphere immobilized platinum catalyst, its difference only is that the chloroplatinic acid-isopropanol solution volume in step (6) is 5mL (amino nano-magnetic silicon sphere carrier and chloroplatinum The weight ratio of chloroplatinic acid in the acid solution is 12.6:1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com