Preparation method for temperature-resistant salt-tolerant oil-displacing foaming agent

A technology of temperature resistance and salt resistance, foaming agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of loss of foaming ability, low oil displacement efficiency, short half-life, etc., to improve temperature resistance and Salt tolerance, improved temperature resistance, effect of improved salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

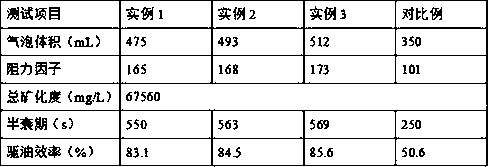

Examples

example 1

[0023] Put 8mL of ethylene into 20mL of toluene, then add 5g of aluminum chloride, heat up to 65°C and react for 1h, add anhydrous magnesium sulfate to dry and distill for 30min, filter and remove the filter residue to obtain self-made alkylbenzene, the volume ratio is 1: 2:3 Mix sulfuric acid solution with a concentration of 1.5mol / L, 1,2-dichloroethane and self-made alkylbenzene in a beaker, react at 16°C for 1 hour, then add 8mL deionized water, and continue the heat preservation reaction 2h, after the reaction, add 16mL of sodium hydroxide solution with a mass fraction of 25% to react for 1h, dry, and discharge to obtain self-made sodium linear alkylbenzene sulfonate. Measure 20mL of polyether and 35mL of sodium carbonate with a mass fraction of 10%. The solution was mixed and stirred for 3 minutes. After stirring, 3g of ethylenediaminetetraacetic acid was added, mixed and stirred for 12 minutes, and heated to 35°C to obtain a self-made mixed solution. 10g of quartz sand wa...

example 2

[0025]Put 9mL of ethylene into 25mL of toluene, then add 6g of aluminum chloride, heat up to 70°C and react for 1.5h, add anhydrous magnesium sulfate to dry and distill for 38min, filter and remove the filter residue to obtain self-made alkylbenzene, the volume ratio is 1 :2:3 Mix sulfuric acid solution with a concentration of 1.5mol / L, 1,2-dichloroethane and self-made alkylbenzene in a beaker, react at 20°C for 1.5h, then add 9mL deionized water, continue Insulated reaction for 3 hours, after the reaction, add 17 mL of sodium hydroxide solution with a mass fraction of 25% to react for 1.5 hours, dry, and discharge to obtain self-made linear alkylbenzene sulfonate, measure 25 mL of polyether, 40 mL of 10% mass fraction The sodium carbonate solution was mixed and stirred for 4 minutes, and after stirring, 4g of ethylenediaminetetraacetic acid was added, mixed and stirred for 14 minutes, and heated to 40°C to obtain a self-made mixed solution. 11g of quartz sand was weighed and g...

example 3

[0027] Pour 10mL of ethylene into 30mL of toluene, then add 7g of aluminum chloride, heat up to 75°C and react for 2h, add anhydrous magnesium sulfate to dry and distill for 45min, filter and remove the filter residue to obtain self-made alkylbenzene, the volume ratio is 1: 2:3 Mix sulfuric acid solution with a concentration of 1.5mol / L, 1,2-dichloroethane and self-made alkylbenzene in a beaker, react at 24°C for 2 hours, then add 10mL deionized water, and continue the heat preservation reaction 4h, after the reaction, add 18mL of 25% sodium hydroxide solution to react for 2h, dry, and discharge to obtain self-made linear alkylbenzene sulfonate, measure 30mL of polyether 45mL of 10% sodium carbonate solution Mix and stir for 5 minutes. After stirring, add 5g of ethylenediaminetetraacetic acid, mix and stir for 16 minutes, and heat up to 45°C to obtain a self-made mixed solution. Weigh 12g of quartz sand and grind it for 10 minutes to obtain quartz sand powder. The mass ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com