Flexible pressure sensor and its preparation method

A pressure sensor and flexible technology, applied in the sensor field, can solve the problems of low sensitivity and high manufacturing cost of flexible pressure sensors, and achieve the effects of fast response time, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

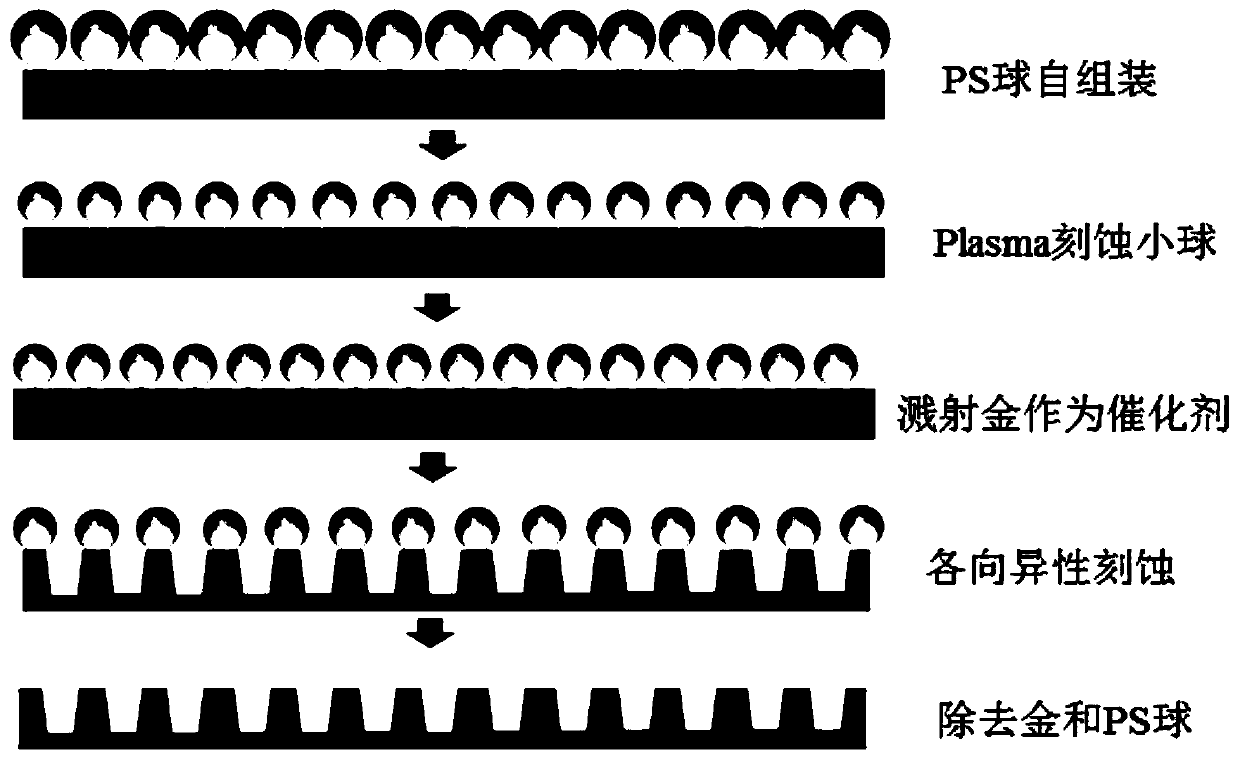

[0038] On the other hand, the embodiment of the present invention also provides a method for preparing a flexible pressure sensor, including the following steps:

[0039] S01: a base plate is provided, and after the surface of the base plate is subjected to hydrophilic treatment, a tightly arranged single-layer colloidal microsphere array is prepared on a surface of the base plate;

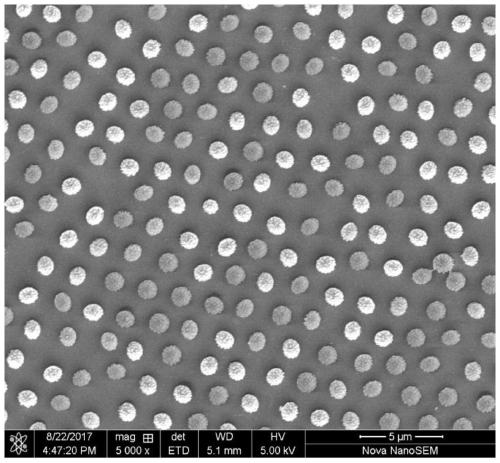

[0040] S02: The single-layer colloidal microsphere array is carried out plasma etching, the diameter of the colloidal microsphere in the described single-layer colloidal microsphere array is reduced, and then one layer of gold film is sprayed, will be sprayed with described gold film The bottom plate is etched with etching solution to form a bottom plate with periodic protrusions;

[0041] S03: Deposit PDMS material on the base plate with periodic protrusions to form a flexible PDMS template with depressions;

[0042] S04: Deposit the conductive composite material in the flexible pressure sensor ...

Embodiment 1

[0051] A method for preparing a flexible PDMS template, comprising the steps of:

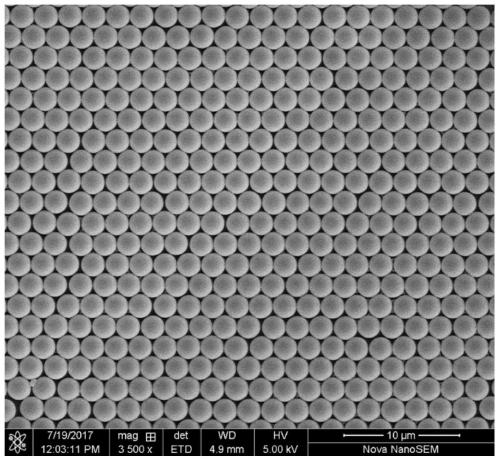

[0052] Such as figure 1 Shown, at first, utilize the method for air-liquid interface self-assembly to prepare the colloidal microsphere array of monolayer close periodic arrangement on the silicon chip, at first will be to the silicon chip (the conductivity of the silicon chip that adopts here adopts in 10 -3 to 10 2 Ω / m) for cleaning treatment, the specific process is: respectively soak the silicon wafer with appropriate amount of acetone, ethanol, deionized water and ultrasonic for 20min to remove impurities on the silicon wafer, and then carry out hydrophilic treatment on the silicon wafer , the specific steps of hydrophilic treatment: first soak and clean with piranha solution (prepared with concentrated sulfuric acid and hydrogen peroxide in a volume ratio of 7:3) for 30 minutes, then clean with a large amount of deionized water, and then put in deionized water, Soak in a mixed solution o...

Embodiment 2

[0056] A method for preparing a flexible pressure sensor, comprising the steps of:

[0057] First, a carbon nanotube / PDMS composite flexible conductive film with a closely arranged truncated conical array is prepared. The specific steps are: firstly, the multi-walled carbon nanotubes with a diameter of 10-200nm and a length of 2-20μm are ultrasonicated in chloroform for 5h, To make it evenly disperse, then use a vortex mixer to mix the multi-walled carbon nanotubes and PDMS prepolymer evenly, heat at 90°C for 6h to remove chloroform, and then mix ethyl acetate and PDMS curing agent (volume mass ratio is 5: 1) Add multi-walled carbon nanotubes and PDMS prepolymer and mix them evenly with a vortex mixer. Then pour the mixed material into the flexible PDMS template obtained in the above-mentioned Example 1, put it into a vacuum oven and heat at 80° C. for 3 hours to cure. After cooling down to room temperature, the two layers of films were slowly separated to obtain a composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com