Powder material for laser melting deposition stainless steel-based composite material, and preparation method

A technology of laser melting deposition and composite material, which is applied in the field of powder and preparation of laser melting deposition TiC reinforced stainless steel matrix composite material, can solve the problems of poor bonding between reinforcement and matrix, easy segregation of reinforcement, high cost, etc. The effect of production cycle, good mechanical properties and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

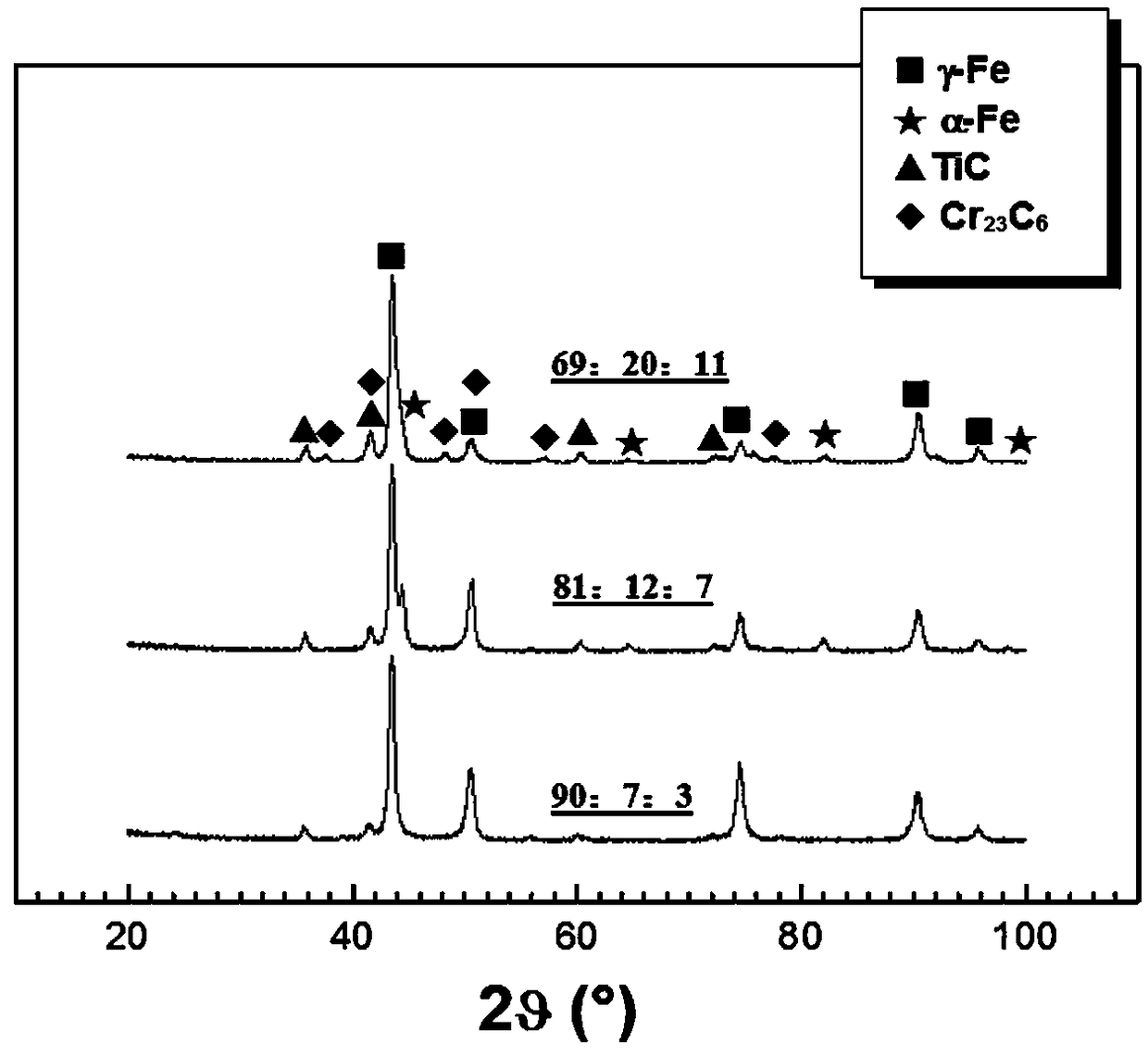

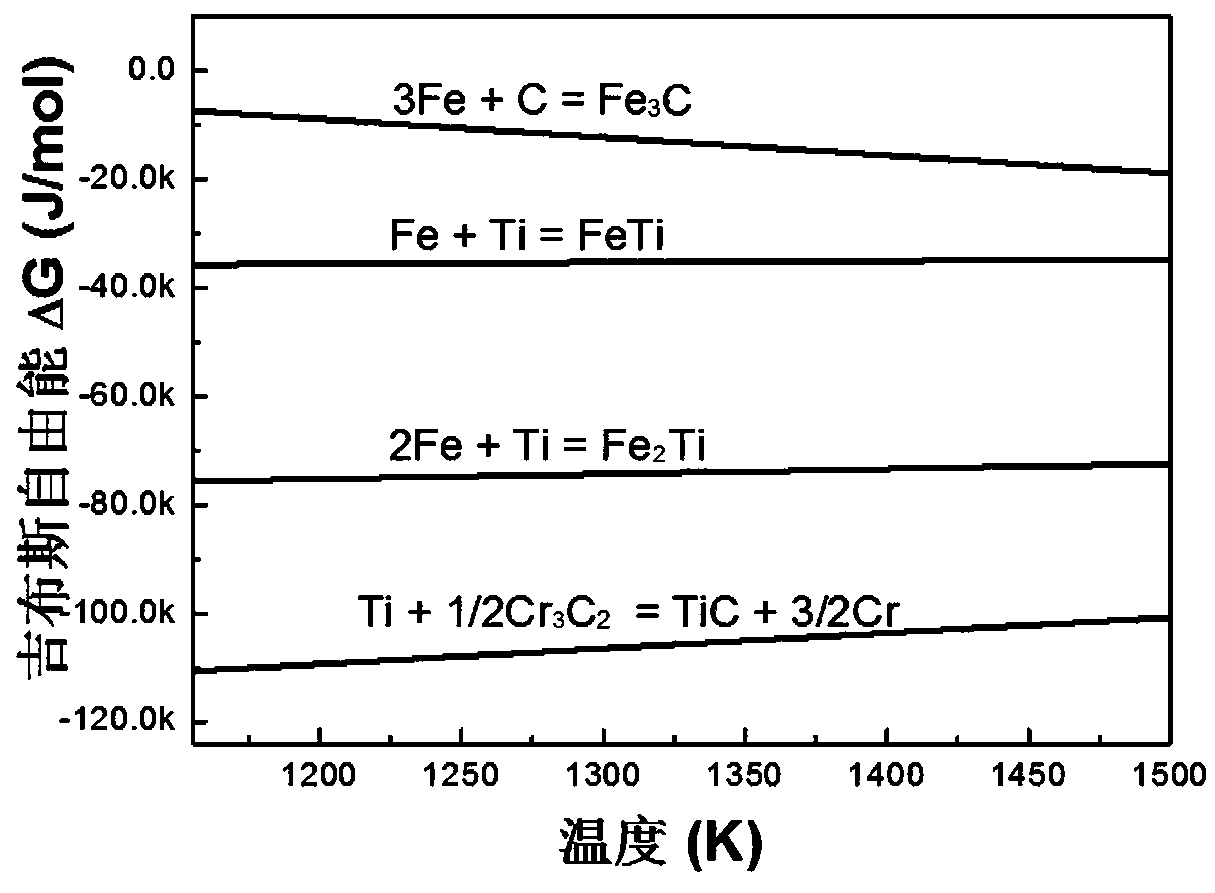

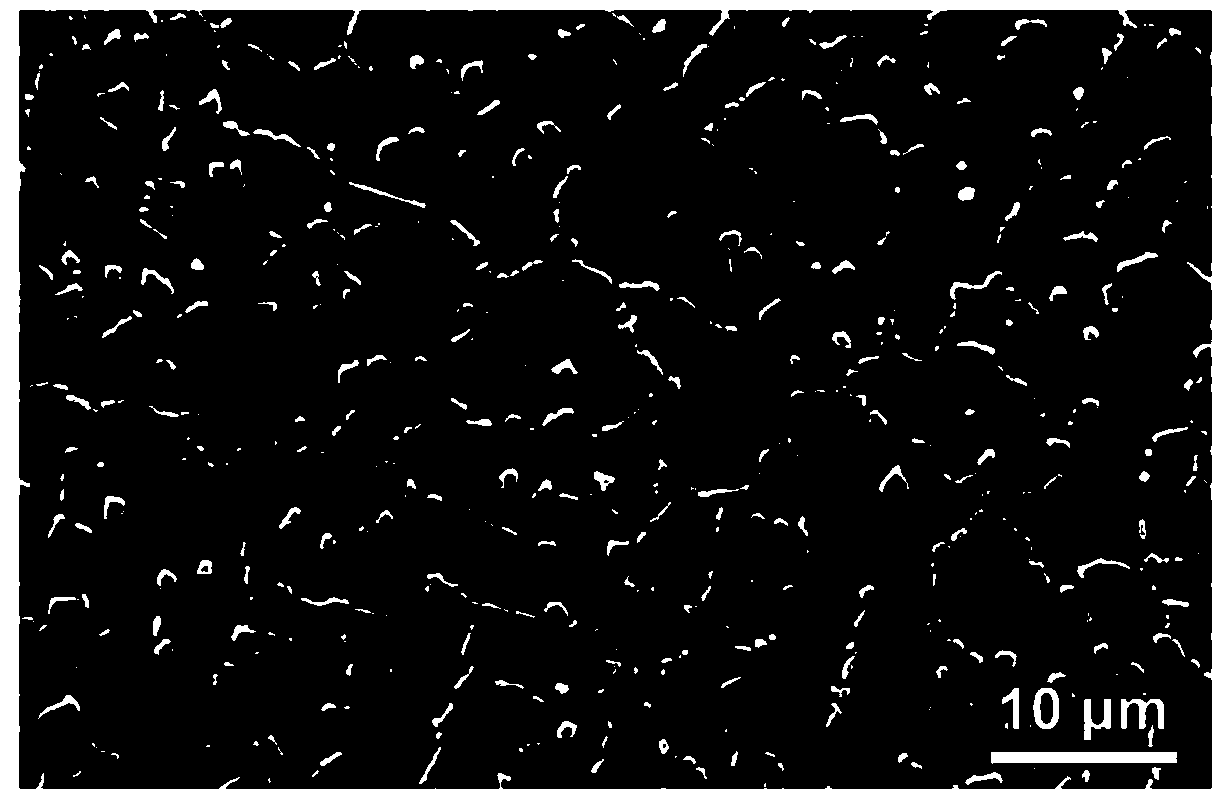

[0032] The invention relates to a powder used for laser melting deposition of stainless steel matrix composite materials and a preparation method thereof. The alloy powder components include stainless steel alloy powder, Cr 3 C 2 powder and Ti powder, the mass fraction of the stainless steel alloy powder is 69%-90%; Cr 3 C 2 The mass fraction of powder is 7%-20%; the mass fraction of Ti powder is 3%-11%. The particle size of alloy powder is 50-180 μm, Cr 3 C 2 The purity of powder and Ti powder is not less than 99.9%.

[0033] The alloy powder with a particle size of 50-180 μm is selected because, when the powder particle size is small (less than 50 μm), the laser melting deposition process is easy to block the powder feeder nozzle, and when the powder particle size is large (greater than 180 μm), the synthesized TiC is enhanced. There are many internal defects in stainless steel matrix composites. If the particle size of the powder is within this range, the utilization ...

Embodiment 1

[0041] Stainless steel alloy powder, Cr 3 C 2 The mass ratio of powder and Ti powder is 90:7:3, and the in-situ synthesis of TiC reinforced stainless steel matrix composite material is prepared by laser melting deposition technology. The specific preparation process steps are:

[0042] According to stainless steel alloy, Cr 3 C 2 The mass ratio of Ti alloy powder and Ti alloy powder is 90:7:3 to prepare in-situ synthesized TiC reinforced stainless steel matrix composite material powder. The prepared alloy powder needs to be ball milled in a planetary ball mill or ground and mixed in a mortar for 2 h, and the uniformly mixed The powder was dried in a vacuum oven at 80 °C for 2 h. The fiber laser processing system is adopted, the laser output power is 2 kW, the spot diameter is 5 mm, the scanning speed is 8 mm / s, the powder feeding rate is 11 g / min, and the overlapping rate of large-area laser beam scanning is 40%. It was carried out in a gas-protected room with an Ar gas fl...

Embodiment 2

[0044] Stainless steel alloy powder, Cr 3 C 2 The mass ratio of powder and Ti powder is 81:12:7, and the in-situ synthesis of TiC reinforced stainless steel matrix composite material is prepared by laser melting deposition. The specific preparation process steps are:

[0045] According to stainless steel alloy, Cr 3 C 2 The mass ratio of Ti alloy powder and Ti alloy powder is 81:12:7 to prepare in-situ synthesized TiC reinforced stainless steel matrix composite powder. The alloy powder needs to be ball milled in a planetary ball mill or ground and mixed in a mortar for 3 h, and the uniformly mixed The powder was dried in a vacuum oven at 80°C for 5 h. The fiber laser processing system is adopted, the laser output power is 2 kW, the spot diameter is 5 mm, the scanning speed is 8 mm / s, the powder feeding rate is 11 g / min, and the overlapping rate of large-area laser beam scanning is 40%. It is carried out in an air chamber with a flow rate of 450 L / h. During laser irradiati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com