Method for synthesizing mordenite (MOR) molecular sieve as well as product and application of molecular sieve

A technology of mordenite and molecular sieve, which is applied in the field of adsorption materials, catalytic materials, and inorganic porous materials, to achieve the effects of good selectivity, simple process and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

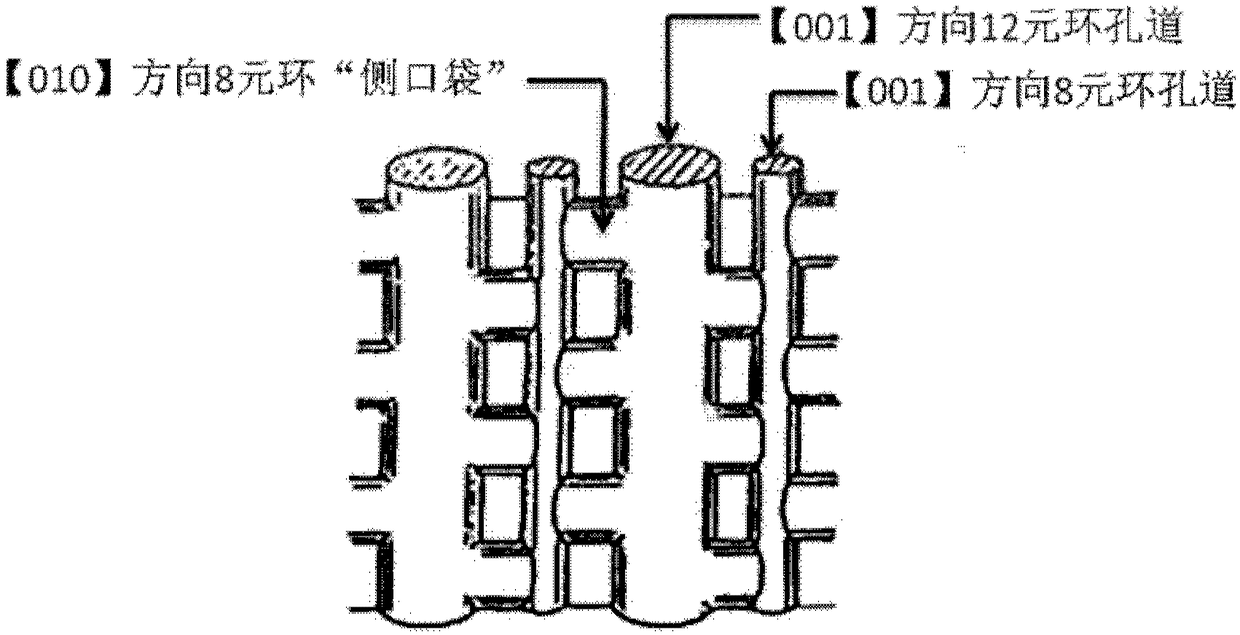

[0044] The synthetic method of the MOR molecular sieve provided by the present invention that can directly adjust the location and distribution of the B acid center includes the following aspects:

[0045] I. the present invention provides a kind of method that synthetic acid center preferentially falls in the mordenite MOR molecular sieve of 8-membered ring " side pocket " in the presence of inorganic bases and comprises the following steps:

[0046] a) will be Al 2 o 3 Aluminum source in terms of SiO 2 Calculated silicon source, inorganic base M 2 O, additional reagent N and water H 2 O is mixed to form an initial mixture A having the following molar ratio composition;

[0047] al 2 o 3 : SiO 2 =0.005~0.1:1

[0048] m 2 O: SiO 2 =0.05~1:1

[0049] N: SiO 2 =0.1~1:1

[0050] h 2 O: SiO 2 =5~60:1;

[0051] b) A certain proportion of mordenite MOR molecular sieve seed crystal S is added to the gel mixture A obtained in step a), and stirred evenly to obtain the i...

Embodiment 1

[0100] Synthesis of Mordenite MOR Molecular Sieve by Adding Additional Reagent Trimethylamine in the Presence of Inorganic Base NaOH

[0101] First, 0.67 g of sodium metaaluminate was dissolved in deionized water, and then 1.88 g of sodium hydroxide was added thereto. After a clear solution was formed, 37.65 g of silica sol (SiO 2 content is 28.5%), 4.54g trimethylammonium, continue stirring at room temperature until forming a uniform silica-alumina gel, then add MOR seed crystal 0.1g to the silica-alumina gel formed to form a mixed raw material, and finally transfer the mixed raw material to the belt In a PTFE-lined stainless steel reactor, dynamic crystallization at 170°C for 48 hours, the molar ratio of the reaction raw materials is as follows: 0.025Al 2 o 3 : SiO 2 : 0.08Na 2 O:0.28TMA:20H 2 O, the product is suction filtered and dried to obtain MOR molecular sieve.

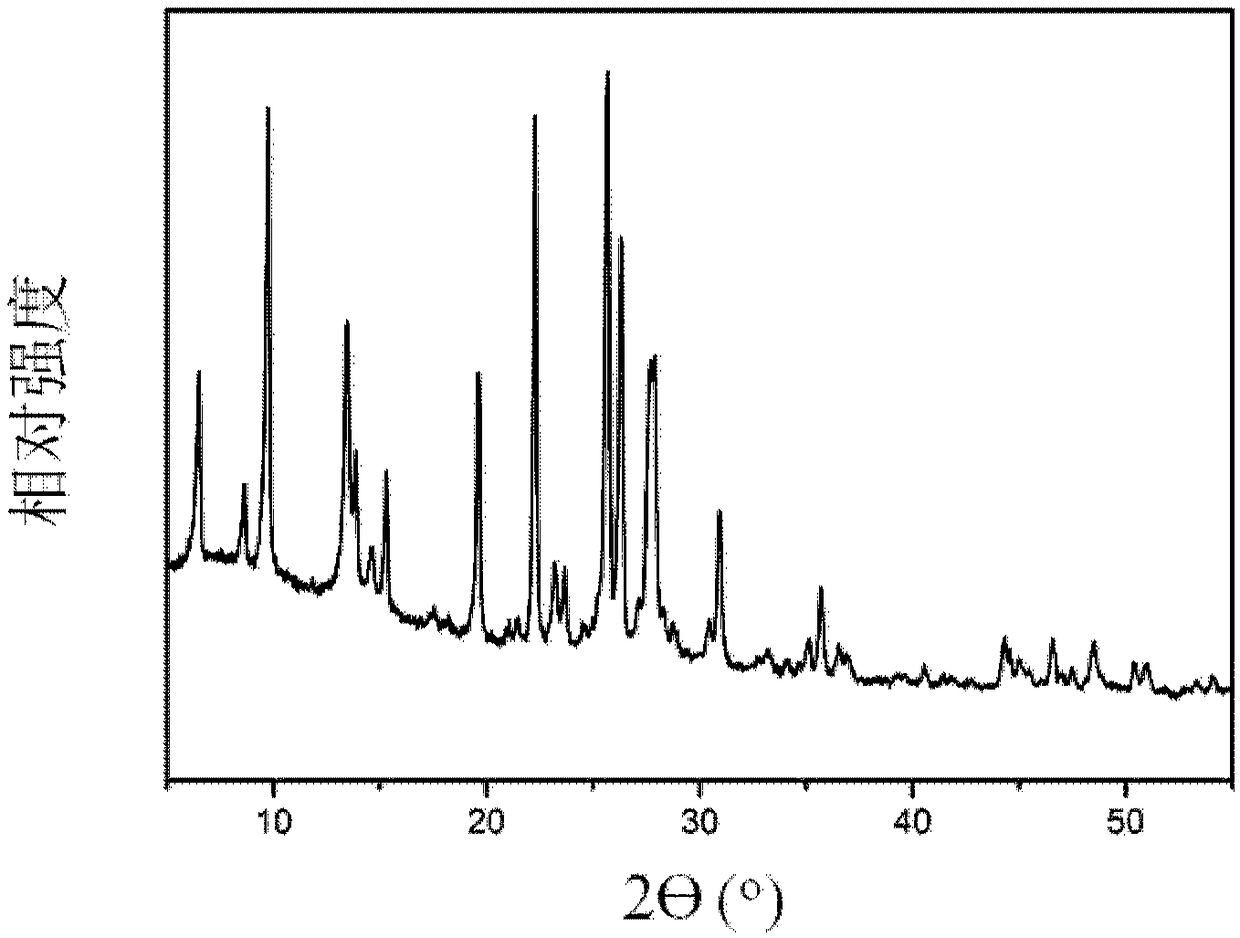

[0102] figure 2 is the XRD pattern of the sample, by figure 2 It can be seen that the obtained ...

Embodiment 2-12

[0109] Example 2-12 Sample 2 # -12 # preparation of

[0110] The specific batching ratio and crystallization conditions are shown in Table 2, and the specific batching process is the same as in Example 1.

[0111] The synthesized samples were analyzed by XRD, and the data results were compared with figure 2 Close, that is, the position and shape of the diffraction peaks are the same, and the relative peak intensity fluctuates in the range of ±5% according to the change of the synthesis conditions, indicating that the synthesis products are all pure-phase mordenite MOR. The sample after roasting and ion exchange is subjected to an acid test, and the test method is the same as in Example 1.

[0112] Table 2 Molecular sieve synthesis ingredients and crystallization conditions table

[0113]

[0114] Note * :Si source: a Silica sol; b white carbon black; c Ethyl orthosilicate; d Methyl orthosilicate; e silicone gel; f water glass; g Coarse porous silica fume; h Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com