A kind of grinding method prepares the method for copper sulfide nano sheet

A nano-sheet, copper sulfide technology, applied in copper sulfide and other directions, can solve problems such as unfavorable large-scale production and time-consuming, and achieve the effects of narrow energy gap, high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

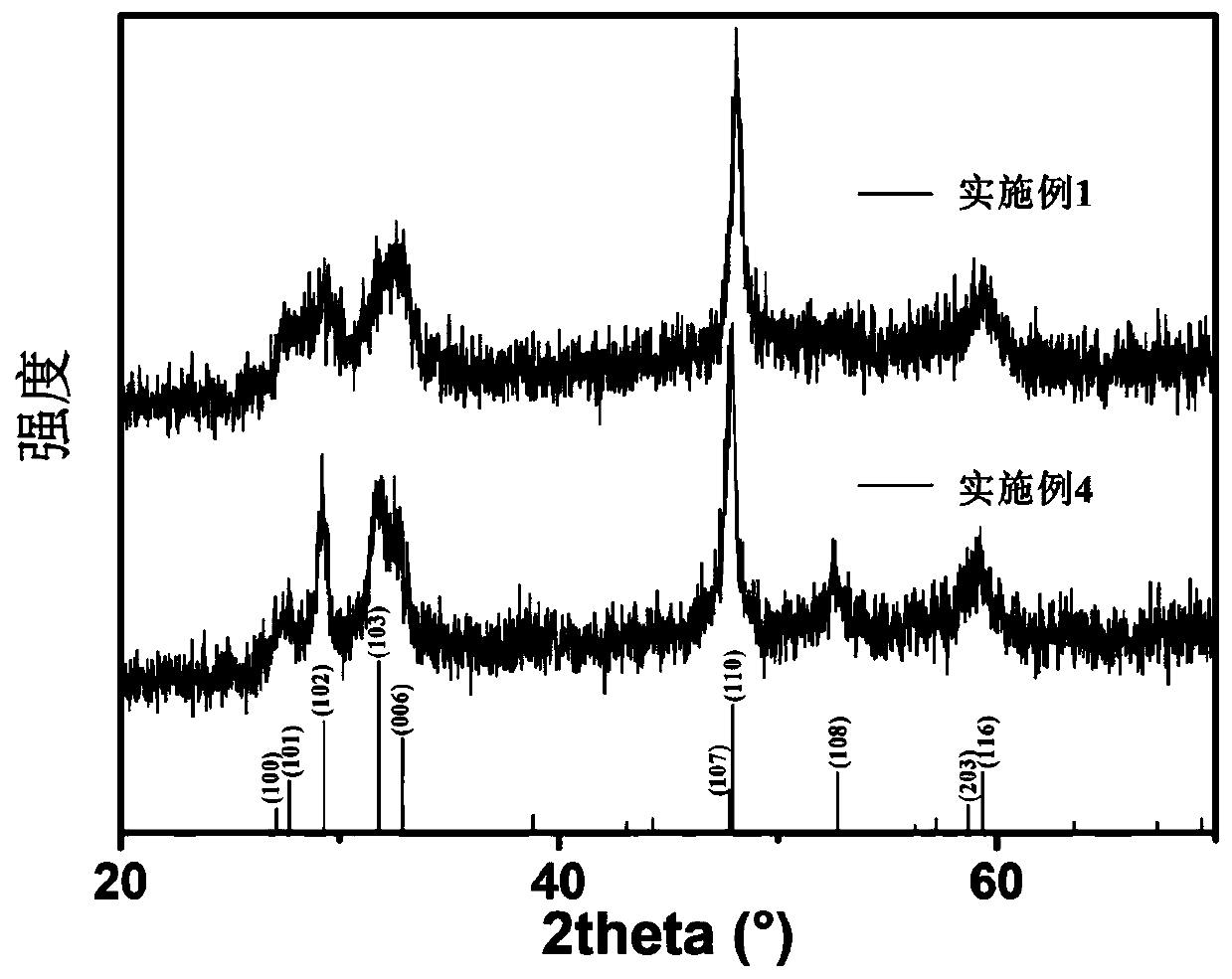

Embodiment 1

[0032] A. Wash the agate mortar and pestle with deionized water and absolute ethanol and dry them. Weigh 0.34g CuCl 2 2H 2 O and 0.31g thiourea were placed in an agate mortar and ground with an agate pestle for 5min to obtain a light green mixture.

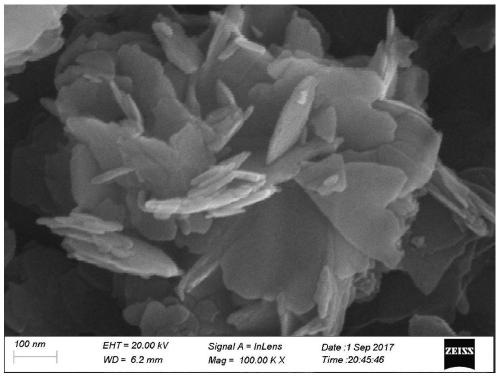

[0033] B. Weigh 0.20g of sodium hydroxide and place it in the mixture obtained in step A, continue grinding for 5min to obtain a black paste mixture. The paste was collected and washed several times by centrifugation with deionized water and absolute ethanol, and then dried at 60°C to obtain a dark green powder that was copper sulfide nanosheets. The obtained copper sulfide nanosheets were weighed, the result was 0.189g, according to CuCl 2 2H 2 The amount of O used calculated a theoretical yield of 0.191 g, thus a yield of 99.0%. Carry out nitrogen adsorption-desorption isotherm test to the copper sulfide nanosheet obtained, the results are shown in Figure 5 According to the BET method, the specific surface area is 23.18m ...

Embodiment 2

[0035] A. Wash the agate mortar and pestle with deionized water and absolute ethanol and dry them. Weigh 0.27g anhydrous CuCl 2 Put it in an agate mortar with 0.31g of thiourea, and grind it with an agate pestle for 5min to obtain a white mixture.

[0036] B. Weigh 0.20g of sodium hydroxide and place it in the mixture obtained in step B, and continue to grind for 5min to obtain a black paste mixture. The paste was collected and washed several times by centrifugation with deionized water and absolute ethanol, and then dried at 60°C to obtain a dark green powder that was copper sulfide nanosheets. The obtained copper sulfide nanosheets were weighed, the result was 0.188g, according to anhydrous CuCl 2 The calculated theoretical yield is 0.191 g, so the yield is 98.4%.

Embodiment 3

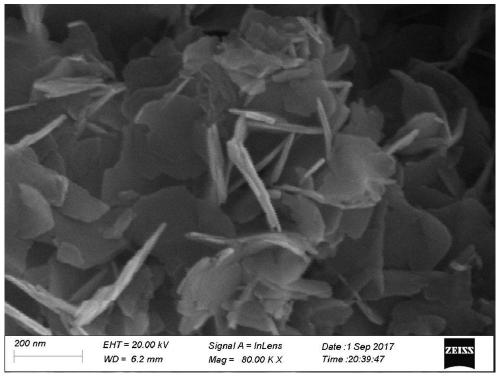

[0038] A. Wash the polytetrafluoroethylene ball mill jar and zirconia grinding balls with deionized water and absolute ethanol and dry them. Weigh 20.5g CuCl 2 2H 2 O and 31.3g of thiourea were placed in a ball mill jar, an appropriate amount of zirconia grinding balls were added, and put into a planetary ball mill to grind for 10 minutes to grind the reactants evenly.

[0039] B. Weigh 16.5g of sodium hydroxide and place it in the mixture obtained in step A. Because the reaction will emit a large amount of gas, first stir the mixture in the ball mill jar with a cleaned and dried glass rod for about 2 minutes until it no longer emits gas and It was black, and then the ball mill jar was sealed and put into a planetary ball mill to continue grinding for 20 minutes to obtain a black paste mixture. The paste was collected and washed several times by centrifugation with deionized water and absolute ethanol, and then dried at 60°C to obtain a dark green powder that was copper sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com