Preparation method of TiO2/PAN nanofiber membrane

A nanofiber membrane and nanocrystal technology, applied in the field of electrospinning, can solve the problems of low photocatalytic performance and anti-aging performance, no market application prospect, and inability to be recycled repeatedly, and achieve strong adsorption and photocatalytic degradation performance, Suitable for widespread application, complete degradation and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

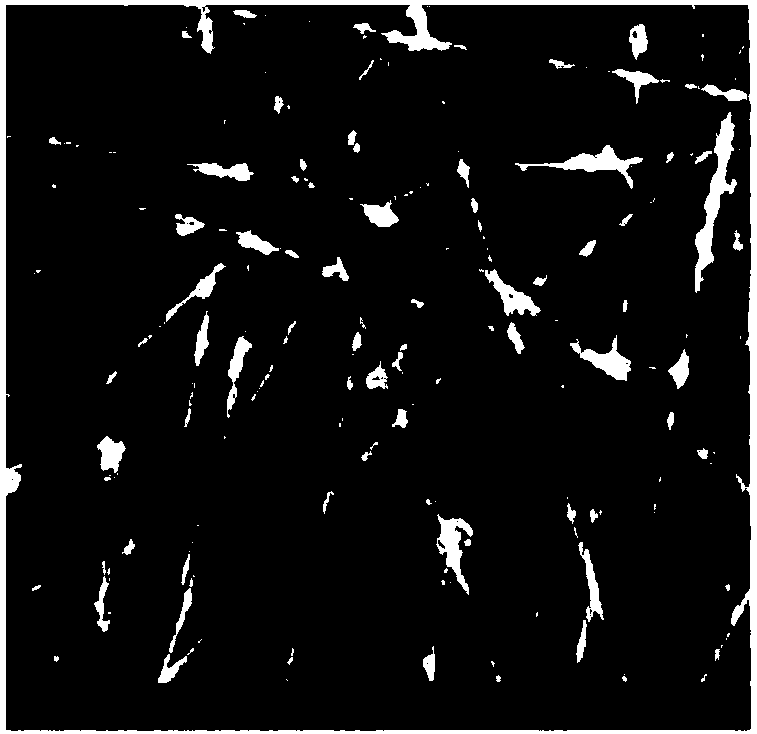

[0039] The first step: at room temperature, weigh the quantitative polyacrylonitrile powder as the solute, select DMF as the solvent, configure a polymer solution with a concentration of 12wt%, put the above solution on a magnetic stirrer and stir at a constant speed for 3 hours, and wait for the polyacrylonitrile powder to After complete dissolution, a light yellow clear and transparent polymer solution was obtained.

[0040] Step 2: Weigh an appropriate amount of TiO with an average particle size of 25nm 2 nanocrystals, will weigh TiO 2 Nanocrystals are dispersed in the prepared polymer solution, in which TiO 2 The mass ratio of nanocrystals to polyacrylonitrile powder is 0.5; wrap the above-prepared solution with tinfoil to completely shield it from light, ultrasonically oscillate for 30 minutes, and stir at a constant speed for 3 hours to obtain TiO 2 Milky white spinning solution with evenly dispersed nanocrystals.

[0041] The third step: control the temperature at ab...

Embodiment 2

[0049] The first step: at room temperature, weigh the quantitative polyacrylonitrile powder as the solute, select DMF as the solvent, configure a polymer solution with a concentration of 12wt%, put the above solution on a magnetic stirrer and stir at a constant speed for 3 hours, and wait for the polyacrylonitrile powder to After complete dissolution, a light yellow clear and transparent polymer solution was obtained.

[0050] Step 2: Weigh an appropriate amount of TiO 2 nanocrystals, will weigh TiO 2 Nanocrystals are dispersed in the prepared polymer solution, in which TiO 2 The mass ratio of nanocrystals to polyacrylonitrile powder is 0.5; wrap the above-prepared solution with tinfoil to completely shield it from light, ultrasonically oscillate for 30 minutes, and stir at a constant speed for 3 hours to obtain TiO 2 Milky white spinning solution with evenly dispersed nanocrystals.

[0051] The third step: control the temperature at about 20°C and the relative humidity at ...

Embodiment 3

[0059] The first step: at room temperature, weigh the quantitative polyacrylonitrile powder as the solute, select DMF as the solvent, configure a polymer solution with a concentration of 12wt%, put the above solution on a magnetic stirrer and stir at a constant speed for 3 hours, and wait for the polyacrylonitrile powder to After complete dissolution, a light yellow clear and transparent polymer solution was obtained.

[0060] Step 2: Weigh an appropriate amount of TiO 2 nanocrystals, will weigh TiO 2 Nanocrystals are dispersed in the prepared polymer solution, in which TiO 2 The mass ratio of nanocrystals to polyacrylonitrile powder is 0.5; wrap the above-prepared solution with tinfoil to completely shield it from light, ultrasonically oscillate for 30 minutes, and stir at a constant speed for 3 hours to obtain TiO 2 Milky white spinning solution with evenly dispersed nanocrystals.

[0061] The third step: control the temperature at about 20°C and the relative humidity at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

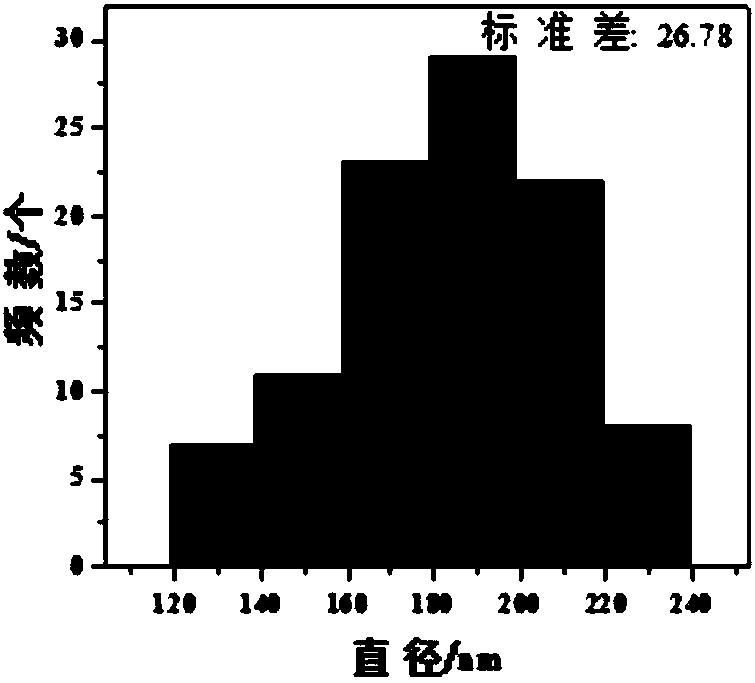

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

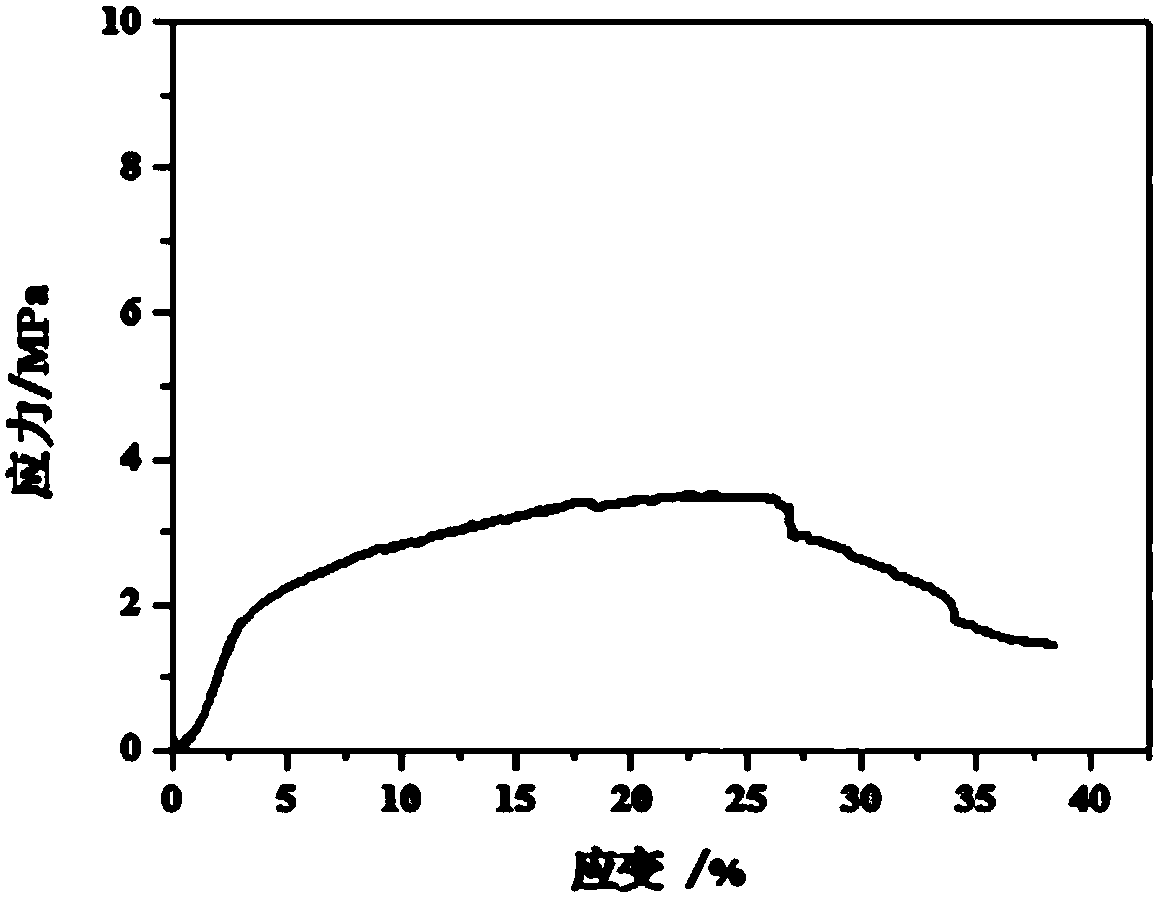

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com