Composite solid electrolyte material and preparation method thereof, and all-solid state electrochromic device

A technology of solid electrolyte and electrolyte, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of lack of bonding performance between PEG electrolyte and substrate, affect the cycle stability and overall performance of the device, ignore the bonding performance, etc., and achieve improved Ionic conductivity and bonding performance, fast discoloration, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

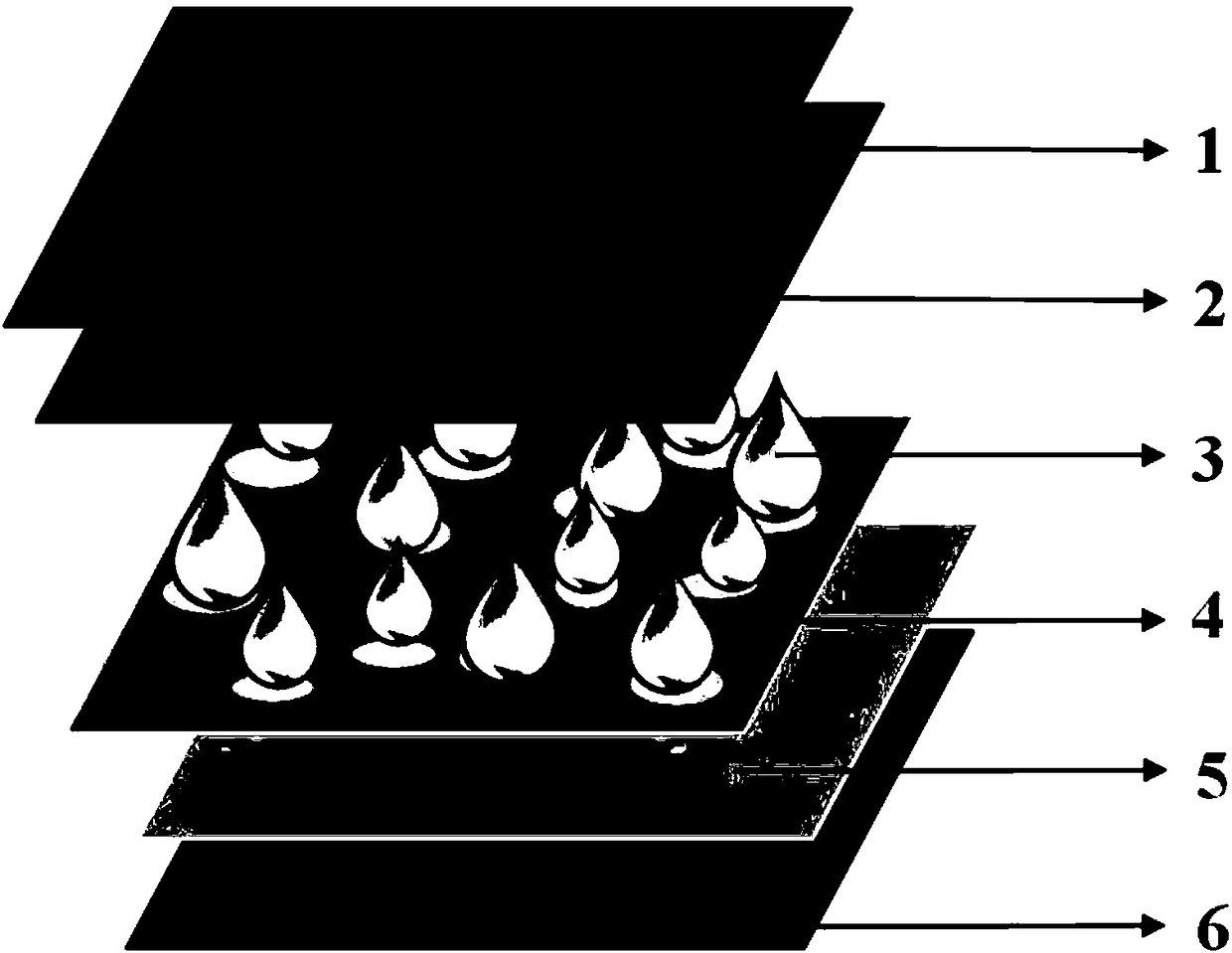

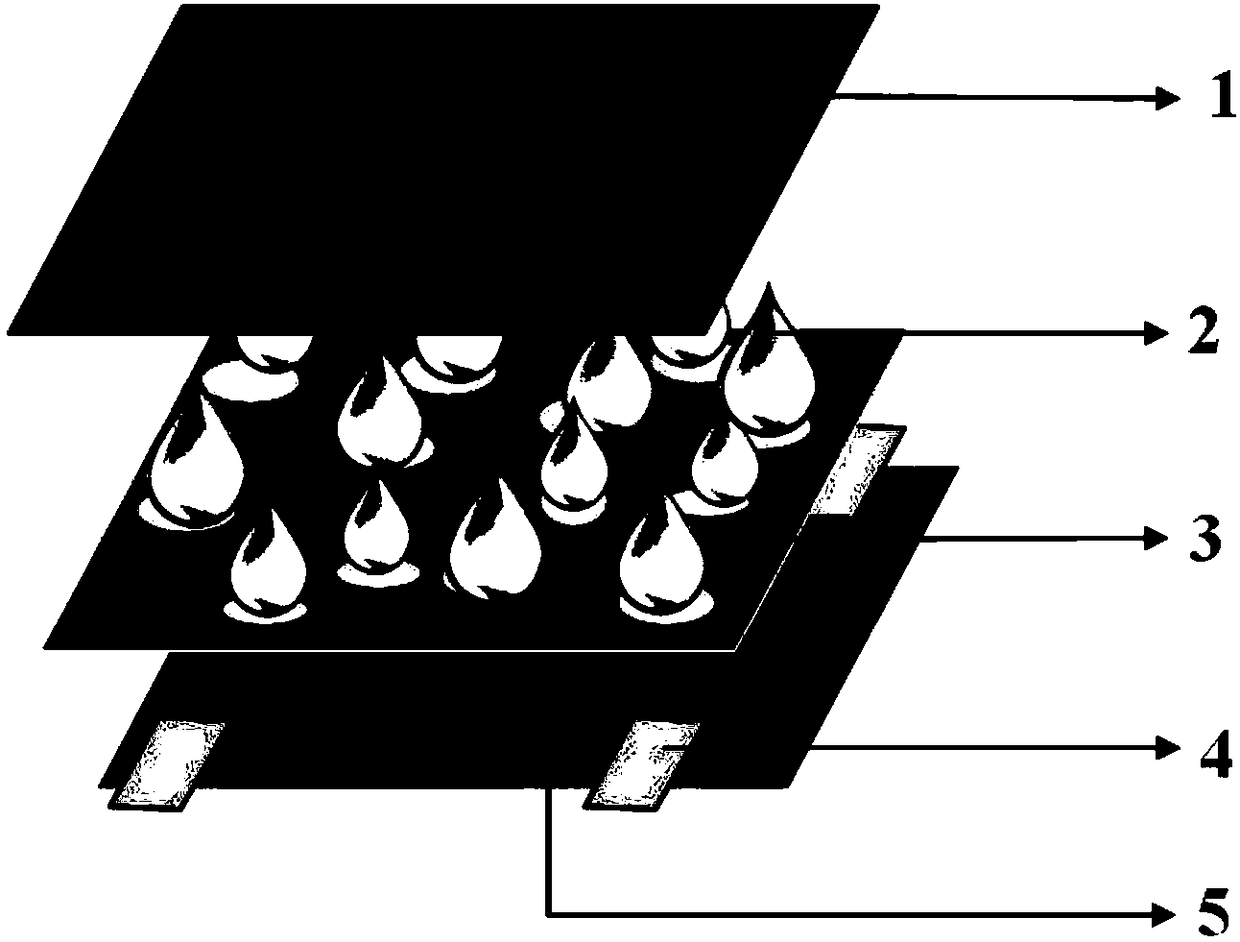

[0041] The present invention also provides a method for preparing the above-mentioned composite solid electrolyte material, comprising the following steps:

[0042] Mix the high-viscosity polymer with the porogen and then spin-coat to obtain a high-viscosity polymer porous membrane;

[0043] Mixing modified polyethylene glycol, transparent photocurable monomer, photoinitiator, lithium salt and low boiling point organic solvent to obtain polyethylene glycol prepolymer;

[0044] The polyethylene glycol prepolymer is filled into the pores of the high-viscosity polymer porous membrane, and after removing the low-boiling point organic solvent, it is cured by ultraviolet light to obtain a composite solid electrolyte material.

[0045] Wherein, the present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0046] After mixing the high-viscosity polymer and the porogen, spin-coat, and after drying, obtain a hig...

Embodiment 1

[0064] 1.1 Synthesis of PEG prepolymer and preparation of PEG electrolyte: take 8.88g isophorone diisocyanate (IPDI), 0.2g p-hydroxyanisole (MEHQ), 0.02g dibutyltin dilaurate (DBTDL) and add 150ml round In the bottom flask, place it in a 60°C oil bath and stir it magnetically until it is in a uniform solution state, add dropwise a mixture of 4.4ml of anhydrous hydroxyethyl acrylate (HEA) and 4.3ml of anhydrous methyl methacrylate (MMA) to react 1 hour; add a solution of 20 g of polyethylene glycol (PEG-1000) in 8.6 ml of methyl methacrylate (MMA) in batches and react for 1.5 hours. Immediately after the reaction, the round-bottomed flask was taken out, and the temperature was slowly lowered at room temperature to obtain a colorless or light yellow PEG-modified liquid. Take 4 g of this liquid, 0.08 g of 1-hydroxycyclohexyl phenyl ketone (HCPK, 2% of the above synthetic liquid), 6 g of 0.1M LiClO 4 / PC (30% of the PEG prepolymer) and 10g of acetonitrile (ACN, 50% of the PEG pre...

Embodiment 2

[0072] Embodiment 2 Comparison test of PVB solid electrolyte with different concentrations

[0073] 2.1 Synthesis of PEG prepolymer:

[0074] Same as the synthesis of the PEG prepolymer in Example 1.

[0075] 2.2 Preparation of PVB porous membrane:

[0076] The preparation of PVB porous film: get chromatographic grade tetrahydrofuran (THF) and dimethyl sulfoxide (DMSO) to prepare mixed solvent according to volume ratio 9:1, get 7wt%, 12wt%, 17wt% PVB solution (PVB is the quality of mixed solvent Fraction) was stirred to a homogeneous colorless liquid by magnetic force. Take 1.72×3.45cm 2 Indium tin oxide (ITO) glass was placed in the center of the coating apparatus, and a layer of PVB solution was dropped on it, and spin-coated under the conditions of 1000rpm and 20s to obtain PVB porous films with different concentrations, with a thickness of 6.7μm.

[0077] 2.3 Preparation of solid electrolyte:

[0078] The method is the same as the preparation of the composite solid el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com