Air-cooled notebook computer with difficultly-weakened heat dispersion property

A notebook computer, cooling performance technology, applied in the direction of energy-saving computing, climate sustainability, electrical digital data processing, etc., can solve the problems of computing performance discount, reduce operating frequency, reduce air intake, etc., to reduce the probability of harm, increase Battery life and the effect of reducing battery loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

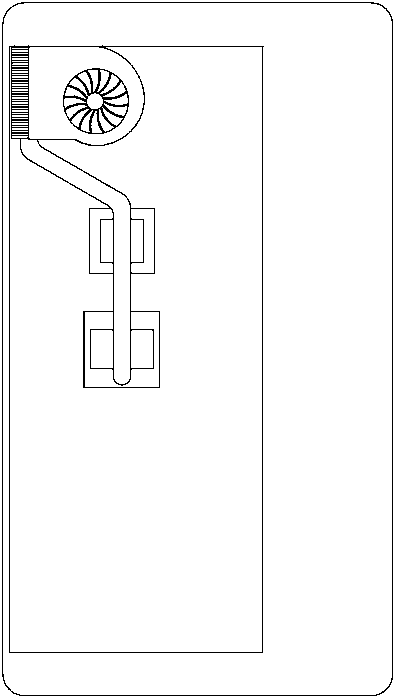

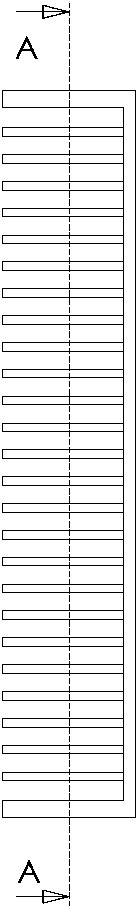

[0049] mainly as Figures 1 to 9 As shown, the heat dissipation module 1 is composed of a heat conduction block 14 , a heat pipe 11 , a radiator 13 , and a fan 12 . The heat conduction block 14, the heat pipe 11, the radiator 13, and the fan mounting cover 121 are integrated by welding; the fan 12 is combined by the fan mounting cover 121 and the fan body 122 through a mounting structure (not shown). The heat sink 13 is composed of several heat dissipation fins 131 , and the gaps between the heat dissipation fins form heat dissipation channels 132 . The designed width of each cooling channel 132 is greater than 1 mm and less than or equal to 2 mm. The heat dissipation module 1 is installed in the body 2, and the heat generated by the CPU3 and GPU4 in the body 2 is absorbed by the heat conduction block 14, then transferred to the heat pipe 11, and then transferred to the radiator 13, the fan 12 and the radiator 13 A relatively airtight air duct is formed, and the airflow gene...

Embodiment 2

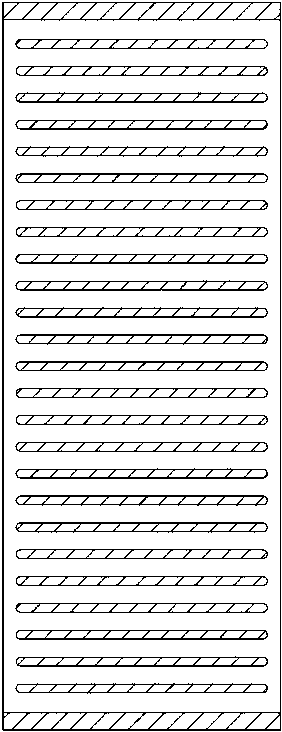

[0051] The difference from Embodiment 1 is that before the bending process, the corresponding edges of the cooling fins 131 are ground or polished or electroplated, or are ground or polished after electroplating. Due to the thinner raw material, the edges can be further streamlined during grinding or polishing (not shown). After the heat dissipation fins 131 are bent and deformed, they are assembled together to form the heat sink 13 and the heat dissipation channel 132 . The design width of the heat dissipation channel 132 is 0.7 to 1 mm; or greater than 1 mm and less than or equal to 2 mm. Alternatively, coating a layer of superhydrophobic paint on the windward edge of the radiator 13 or the heat dissipation fin 131 can also effectively prevent filamentous and flocculent dust from being caught by the edge of the fin.

Embodiment 3

[0053] mainly as Figures 10 to 11 As shown, different from the above embodiments, the radiator 13 is manufactured by a forging process, and the windward surface of the radiator 13 for increasing the specific surface area has a streamlined shape, or the windward edge of the cross section perpendicular to the thickness direction of the product has an outer surface. Curved and has a smooth surface. The length of the part where the fan mounting cover 121 is combined with the radiator 13 is increased (not shown in the figure), and the function is to form a relatively airtight heat dissipation channel 132 together with the radiator 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com