Preparation method of anode material of lithium-sulphur battery

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of material structure collapse, active material loss, and impact on battery cycle performance, achieve good electrical conductivity and mechanical strength, improve Cycle performance, effect of relieving internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of lithium-sulfur battery positive electrode material of the present invention, it specifically comprises the following steps:

[0036] S1. Dispersing the carbon material in a solvent to form a mixed suspension. Wherein, the carbon material is one or more of graphite, graphene, graphene oxide, reduced graphene oxide, soft carbon, hard carbon, porous carbon, carbon nanotube, carbon nanofiber and hollow carbon sphere; The solvent is one or more of deionized water, ethanol, ethylene glycol, n-propanol, isopropanol, propylene glycol, n-butanol and carbitol.

[0037] S2. Put the sulfur-containing substance into the mixed suspension and perform ultrasonication for 2 hours, adjust the mixed suspension to be neutral or weakly acidic with an acid solution, filter with suction, and wash to obtain a sulfur-carbon composite material. Wherein, the mass ratio of the carbon material to the sulfur element in the sulfur-containing substance is 1:0.5. The sulfur-...

Embodiment 2

[0040] The preparation method of lithium-sulfur battery positive electrode material of the present invention, it specifically comprises the following steps:

[0041] S1. Dispersing the carbon material in a solvent to form a mixed suspension. Wherein, the carbon material is one or more of graphite, graphene, graphene oxide, reduced graphene oxide, soft carbon, hard carbon, porous carbon, carbon nanotube, carbon nanofiber and hollow carbon sphere; The solvent is one or more of deionized water, ethanol, ethylene glycol, n-propanol, isopropanol, propylene glycol, n-butanol and carbitol.

[0042] S2. Put the sulfur-containing substance into the mixed suspension and perform ultrasonication for 24 hours, adjust the mixed suspension to be neutral or weakly acidic with an acid solution, filter with suction, and wash to obtain a sulfur-carbon composite material. Wherein, the mass ratio of the sulfur element in the carbon material to the sulfur-containing substance is 1:9. The sulfur-c...

Embodiment 3

[0045] The preparation method of lithium-sulfur battery positive electrode material of the present invention, it specifically comprises the following steps:

[0046] S1. Dispersing the carbon material in a solvent to form a mixed suspension. Wherein, the carbon material is one or more of graphite, graphene, graphene oxide, reduced graphene oxide, soft carbon, hard carbon, porous carbon, carbon nanotube, carbon nanofiber and hollow carbon sphere; The solvent is one or more of deionized water, ethanol, ethylene glycol, n-propanol, isopropanol, propylene glycol, n-butanol and carbitol.

[0047] S2. Put the sulfur-containing substance into the mixed suspension and perform ultrasonication for 12 hours, adjust the mixed suspension to be neutral or weakly acidic with an acid solution, filter with suction, and wash to obtain a sulfur-carbon composite material. Wherein, the mass ratio of the carbon material to the sulfur element in the sulfur-containing substance is 1:5. The sulfur-c...

PUM

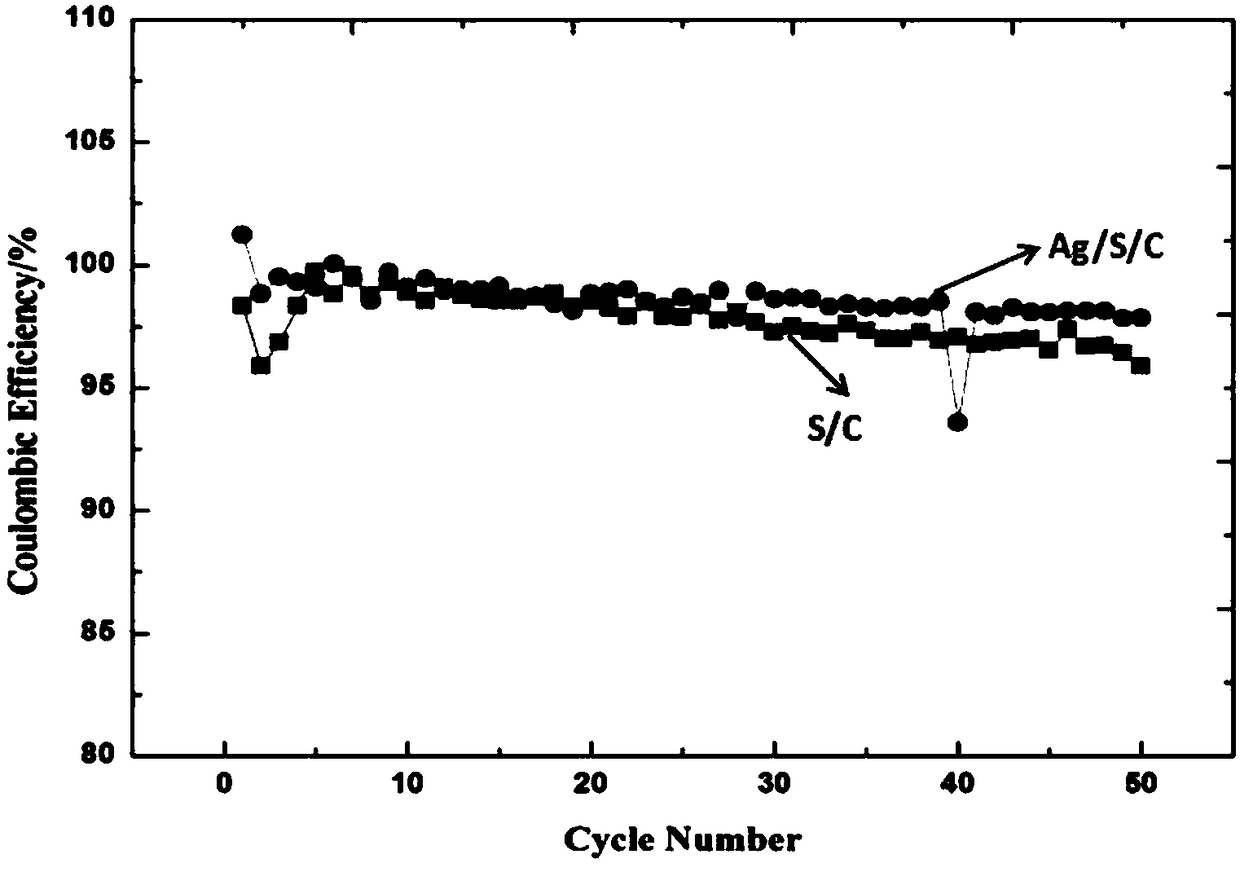

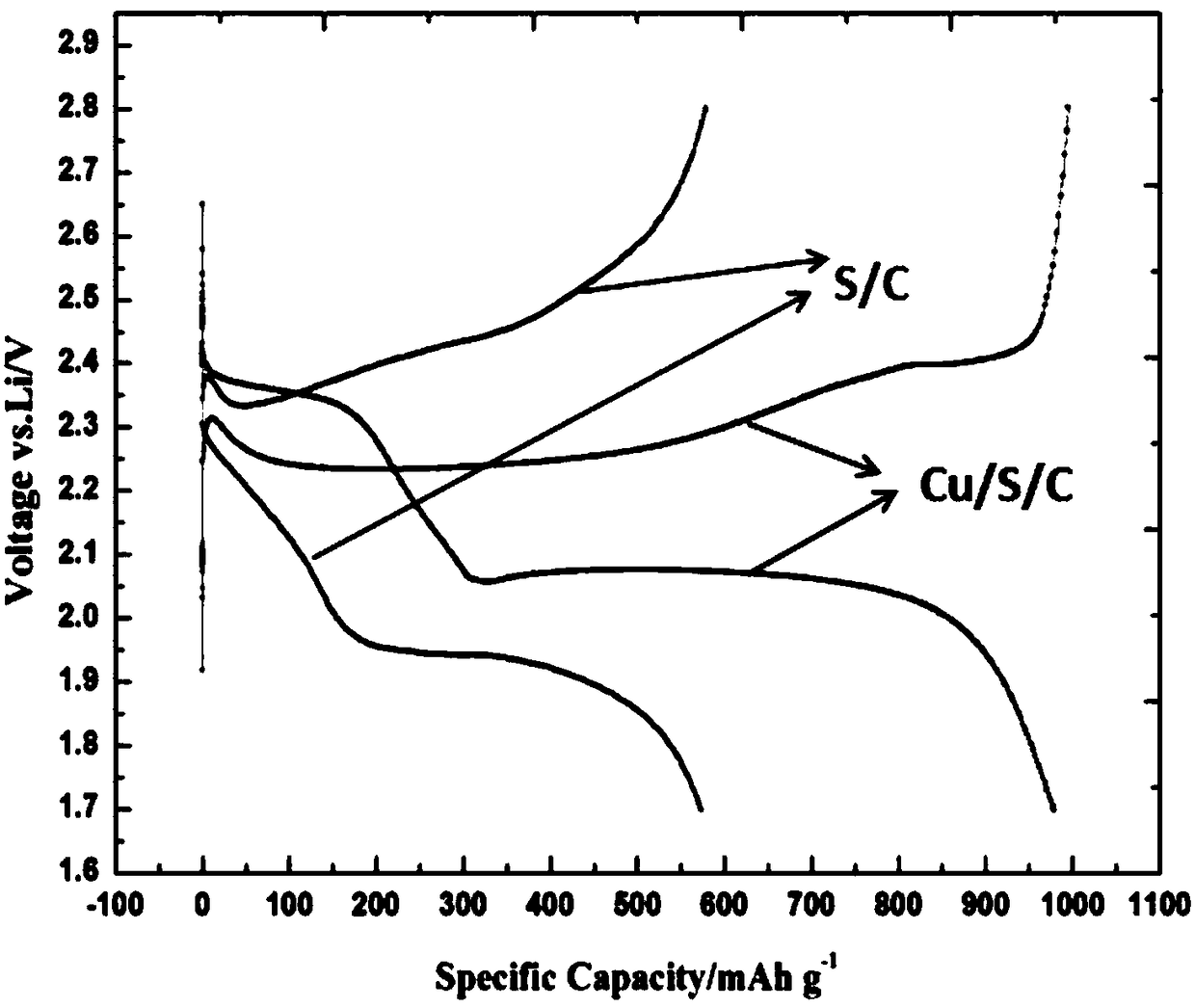

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com