Organic waste gas treatment system and solvent recovery technology

A technology of organic waste gas and treatment system, which is applied in the direction of solid adsorbent liquid separation, dispersed particle filtration, and dispersed particle separation, etc. It can solve the problems of low solvent recovery rate, unsatisfactory organic waste gas treatment effect, high energy consumption, etc., and achieve reduction Energy consumption, avoiding drying treatment, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

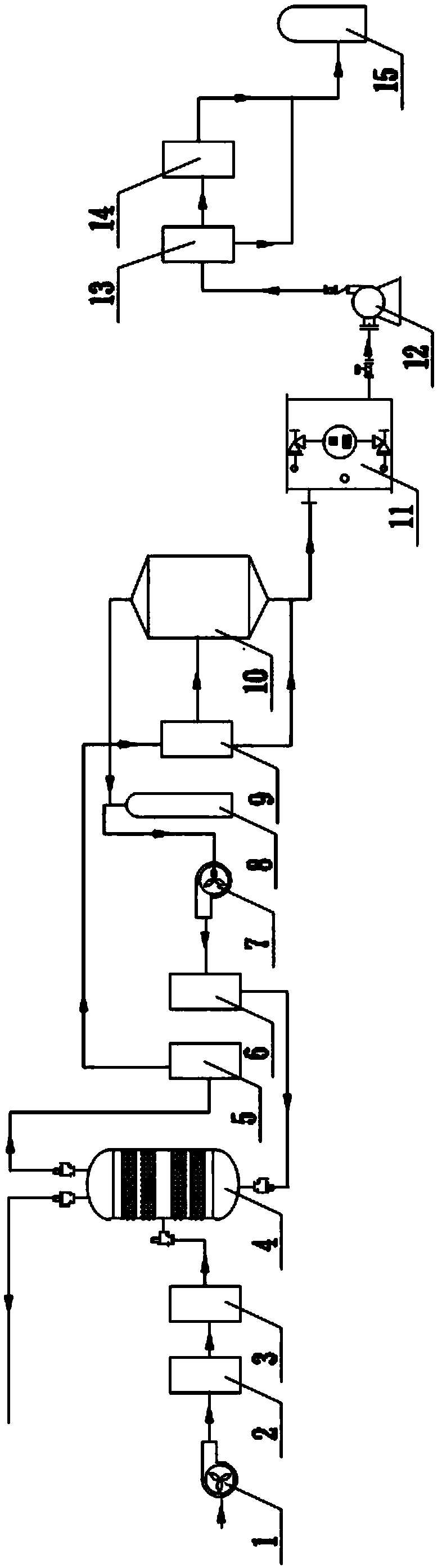

[0026] An organic waste gas treatment system, such as figure 1 As shown, it includes a pretreatment system, an exhaust gas adsorption system, a nitrogen desorption system and a solvent refining system, wherein the pretreatment system includes a surface cooler 2 and a filter 3 connected in sequence; the exhaust gas adsorption system includes an activated carbon particle adsorber 4, and the filter Device 3 communicates with activated carbon particle adsorber 4; nitrogen desorption system includes heat exchanger 5, heater 6, desorption fan 7, nitrogen buffer tank 8, condenser 9, gas-liquid separator 10 and solvent buffer tank 11, activated carbon The particle adsorber 4 is connected to the heat exchanger 5, the condenser 9, the gas-liquid separator 10 and the solvent buffer tank 11 successively, the condenser 9 is also connected to the solvent buffer tank 11, and the gas-liquid separator 10 is successively connected to the nitrogen buffer tank 8, the degasser The fan 7, the heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com