Catalyst for preparing hydrocarbons by one-step hydrogenation of carbon dioxide and preparation method thereof

A carbon dioxide and catalyst technology, which is applied to the catalyst for preparing hydrocarbons by one-step hydrogenation of carbon dioxide and the field of preparation thereof, can solve problems such as unfavorable methanol and low methane, and achieve the effects of reducing production cost, small particle size and high target product selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

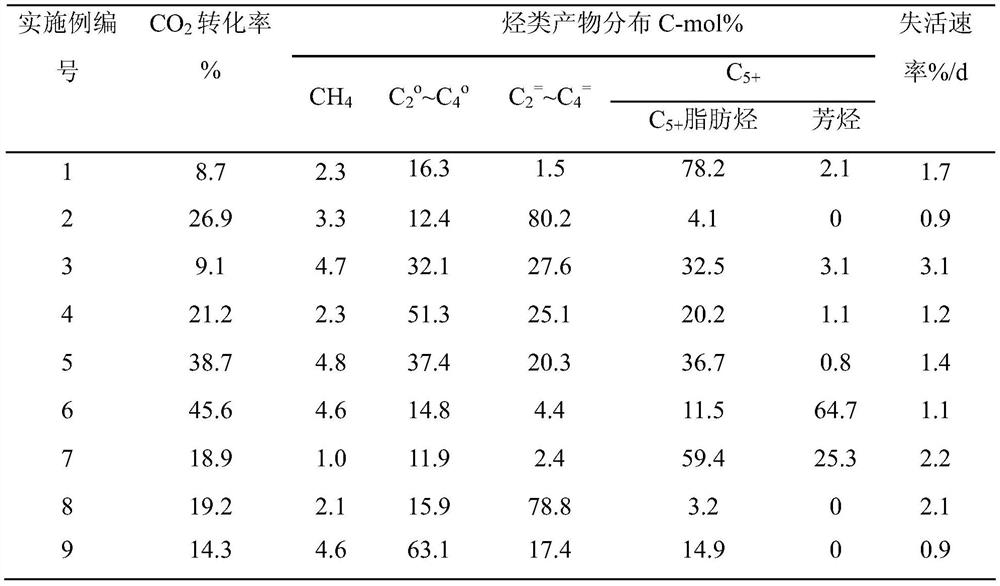

Examples

Embodiment 1

[0044] 40.4g Fe(NO 3 ) 3 9H 2 O was added to 1L deionized water to prepare a mixed metal salt solution with a metal ion concentration of 0.1mol / L, and 5.30g of sodium carbonate was added to a mixed solution of 0.25L deionized water and 0.25L absolute ethanol to prepare a 0.1mol / L solution. L of precipitant solution, add the precipitant solution dropwise to the metal salt solution at 20°C, the dropping process needs to be fully stirred, the final pH value is kept at 9, and the resulting product is stirred at 70°C after the precipitation reaction After aging for 4 hours under high temperature, the resulting precipitate was washed several times with deionized water, then dried at 80°C for 12 hours, and then calcined at 350°C for 4 hours to obtain a metal oxide, which was characterized by a particle size of 20nm and a specific surface area of 75m 2 / g. Set the specific surface area to 500m 2 / g, the mesopore diameter is 4.1nm, and the mesopore volume is 0.41cm 3 / g of hiera...

Embodiment 2

[0047] 13.32g Cr(NO 3 ) 2 9H 2 O and 28.62g Zr(NO 3 ) 4 ·5H 2 O was added to a mixed solution of 0.1L water and 0.025L absolute ethanol to prepare a mixed metal salt solution with a metal ion concentration of 0.8mol / L, and 3.3mL ammonia water was added to a mixed solution of 0.05L absolute ethanol to make 1mol / L of precipitant solution, add the precipitant solution dropwise to the metal salt solution at 25°C, the dropping process needs to be fully stirred, the final pH value is kept at 10, and the resulting product is stirred at 60°C after the precipitation reaction is completed Aged for 6 hours under the same conditions, then the obtained precipitate was washed several times with deionized water, then dried at 60°C for 18 hours, and then calcined at 300°C for 3 hours to obtain a metal oxide, which was characterized by a particle size of 10nm and a specific surface area of 136m 2 / g, tableted and sieved into 20-40 mesh. The specific surface area is 340m 2 / g, the meso...

Embodiment 3

[0050] 41.79g Ga(NO 3 ) 3 ·xH 2 O was added to the mixed solution of 0.12L water and 0.08L absolute ethanol to prepare a metal ion concentration of 0.5mol / L mixed metal salt solution, and 3.3mL ammonia water was added to the mixture of 0.01L deionized water and 0.02L absolute ethanol Prepare a 1.67mol / L precipitant solution in the mixed solution, and add the precipitant solution dropwise to the metal salt solution at 15°C. The dropping process needs to be fully stirred, and the final pH value is kept at 11. After the precipitation reaction is completed, the The obtained product was aged at 100°C for 1.5h, then the obtained precipitate was washed several times with deionized water, then dried at 60°C for 24h, and then calcined at 300°C for 7h to obtain a metal oxide. The diameter is 23nm and the specific surface area is 112m 2 / g. The specific surface area of molecular sieve is 445m 2 / g, the mesopore diameter is 4.39nm, and the mesopore volume is 0.49cm 3 / g Hierarchic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com