Reinforced hollow fiber membrane, preparation method and applications thereof

An enhanced fiber membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor binding force, unsatisfactory binding strength, complicated preparation process, etc., and achieve strong binding ability, high water Effect of flux, high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

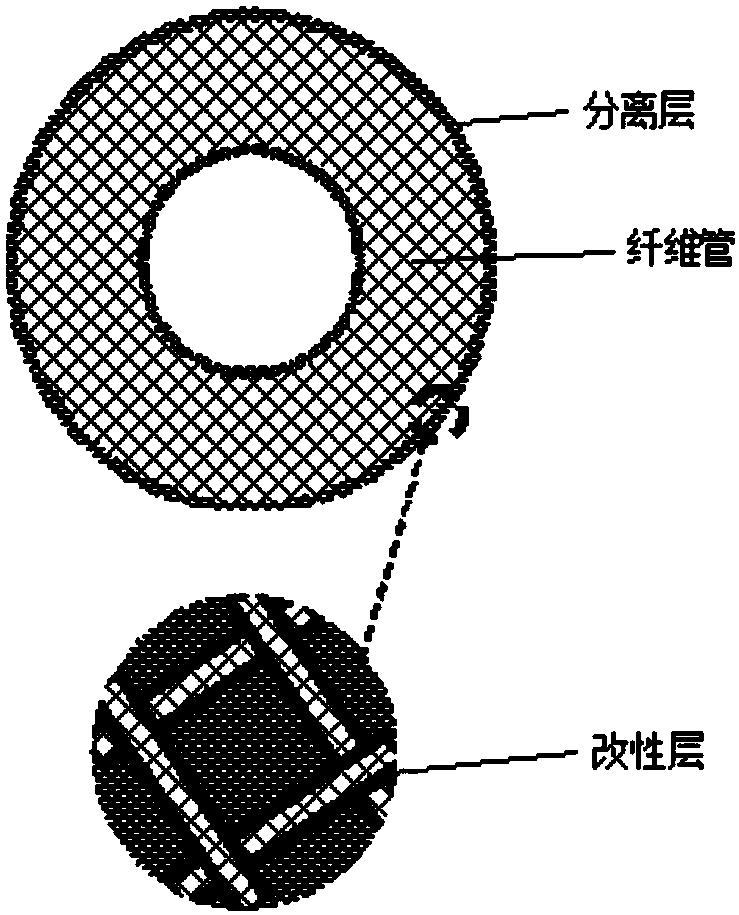

[0058] One aspect of the present invention provides a method for preparing a reinforced hollow fiber membrane, the method comprising:

[0059] (1) In an alkaline solution, the fiber filaments are activated to obtain activated fiber filaments;

[0060] (2) In the modification solution, the activated fiber filaments are impregnated with a modification composition to obtain modified fiber filaments;

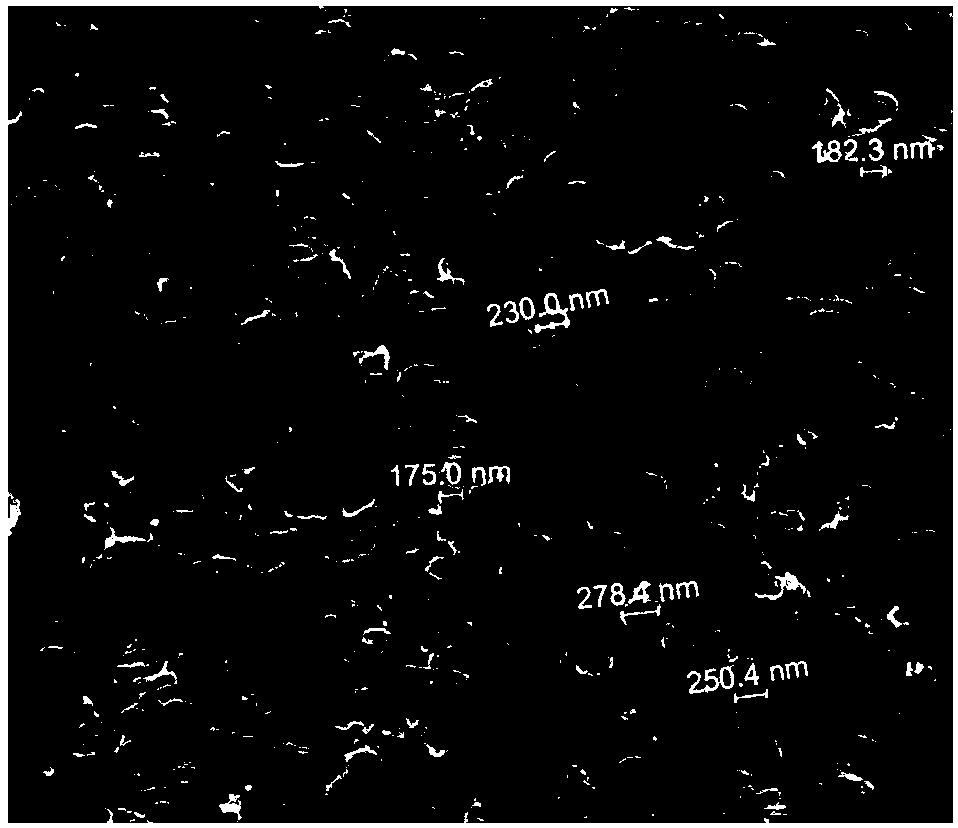

[0061] (3) in the metal salt solution, contacting the modified fiber filament with the metal salt to obtain a fiber filament with nanoparticles on the surface;

[0062] (4) mixing the fiber filaments with nanoparticles on the surface with the membrane-making solution, and braiding the resulting mixture to obtain a hollow fiber braided tube;

[0063] (5) forming the hollow fiber braided tube into a reinforced hollow fiber membrane;

[0064] Wherein, the modified composition contains a first polyphenolic compound and crosslinking molecules; the film-forming solution contains a film-...

Embodiment approach

[0180] According to a preferred embodiment of the present invention, the weaving is: the silver-containing fiber bundle and the polymer fiber bundle are cross-braided in a "herringbone" shape along the core liquid tube.

[0181] Preferably, the polymer fiber bundle is composed of 100-1000 fiber filaments. Preferably, the silver-containing fiber bundle is composed of 1-10 silver-containing fiber filaments.

[0182] According to the present invention, the silver-containing fiber bundles can be obtained commercially or by self-made.

[0183] According to a preferred embodiment of the present invention, the fiber filaments are selected from at least one of polyester fibers, polyamide fibers, polyolefin fibers, polyamide fibers, polyurethane fibers, polysulfone fibers or glass fibers, preferably polyester fibers and / or or polyamide fibers.

[0184] According to a preferred embodiment of the present invention, the casting solution used in step 2) includes polyvinylidene fluoride, ...

preparation example 1-6

[0207] According to the composition in Table 1 (the kind of each compound and the concentration in modified solution are as listed, wherein, concentration refers to the net mass of each compound accounts for the percentage of modified solution gross weight), the reagent under each modified solution Mix to obtain corresponding modified solutions respectively, in Table 1:

[0208] Polyethyleneimine is purchased from aldrich company, and its number average molecular weight is 3000;

[0209] Tannic acid was purchased from Aladdin Reagent Company;

[0210] Polyethylene glycol was purchased from Sinopharm Chemical Reagent Co., Ltd., and its number average molecular weight was 1000.

[0211] Modified solution preparation comparative example 1

[0212] According to the preparation of modified solution 1, the difference is that no polyethyleneimine is added and an equal amount of dopamine is used instead of polyethyleneimine, thereby obtaining modified solution DA1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com