A high-capacity macroporous polymer cation exchange chromatography medium and its preparation

A technology for cation exchange and chromatography medium, which is applied in the field of high-capacity, large-pore size polymer cation exchange chromatography medium and its preparation, can solve the problems of increased preparation cost, many reaction steps, waste, etc., and achieves high mechanical strength and fluidity. Mass transfer performance, fast operating flow rate, and small reaction steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: High-capacity large-pore diameter PGMA-EDMA cation exchange chromatography medium

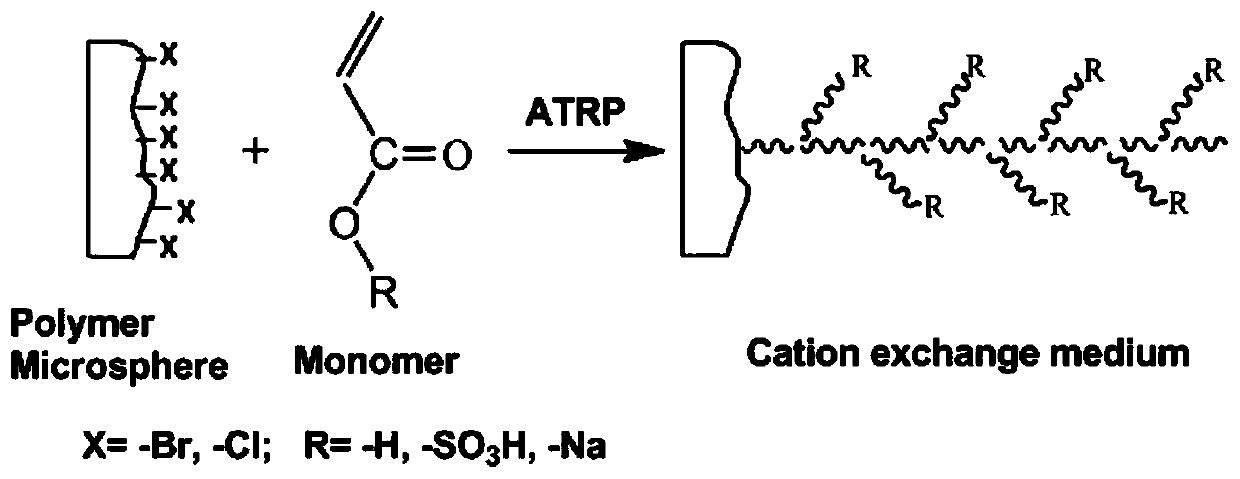

[0033] Schematic diagram of the preparation process of cation exchange chromatography medium by graft copolymerization on the surface of macroporous polymer microspheres. figure 1 .

[0034] The preparation method of high-capacity large-pore diameter PGMA-EDMA cation exchange chromatography medium comprises the following steps:

[0035] (1) Swelling treatment of macroporous polyglycidyl methacrylate-ethylene glycol dimethacrylate (PGMA-EDMA) microspheres (average pore size 128nm) in acrylic acid solution

[0036] Accurately weigh 1.0 g of PGMA-EDMA microspheres and put them into a 50 mL three-necked reaction flask, then add 3.0 mL of acrylic acid dimethyl sulfoxide solution, swell for 2.0 h under mechanical stirring at 100 rpm, and fill high-purity nitrogen for protection during the swelling process .

[0037] (2) Acrylic acid grafted on the surface of PGMA-EDMA microsph...

Embodiment 2

[0048] Embodiment 2: High-capacity large-pore PEDMA cation-exchange chromatography medium

[0049] The preparation method of high-capacity large-pore PEDMA cation exchange chromatography medium comprises the following steps:

[0050] (1) Swelling treatment of macroporous PEDMA microspheres (average pore diameter 687nm) in 2-acrylamido-2-methyl-1-propanesulfonic acid solution

[0051] Accurately weigh 1.0g of PEDMA microspheres into a 50mL three-neck reaction flask, then add 5.0mL of dimethylformamide solution of 2-acrylamido-2-methyl-1-propanesulfonic acid, and swell under mechanical stirring at 100rpm 1.0h, filled with high-purity nitrogen for protection during swelling treatment.

[0052] (2) Graft polymerization of 2-acrylamido-2-methyl-1-propanesulfonic acid on the surface of PEDMA microspheres

[0053] Weigh 0.049g CuCl (1 / 20 mass of microspheres) and 0.147g tetramethylethylenediamine (TMEDA) (3 times the mass of CuCl) and add them to the microspheres after swelling tre...

Embodiment 3

[0055] Embodiment 3: High capacity large pore size PSt-EDMA cation exchange chromatography medium

[0056] The preparation method of PSt-EDMA cation exchange chromatography medium with high loading capacity and large pore size comprises the following steps:

[0057] (1) Macroporous PSt-EDMA microspheres (average pore size 2100nm) are pretreated in methacrylic acid solution

[0058] Accurately weigh 1.0 g of PSt-EDMA microspheres into a 50 mL three-necked reaction flask, then add 10 mL of methacrylic acid in dioxane solution, swell for 0.5 h under mechanical stirring at 100 rpm, and fill high-purity nitrogen gas for protection during the swelling process .

[0059] (2) Grafting and polymerizing methacrylic acid on the surface of macroporous PSt-EDMA microspheres

[0060] Weigh 0.016g CuCl (1 / 60 mass of microspheres) and 0.048g N,N,N,'N,"N,"'-pentamethyldiethylenetriamine (PMDETA) (3 times the mass of CuCl) and add Into the microspheres after the swelling treatment in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com