A kind of thermosensitive bisphenol A imprinted polymer microsphere and its application

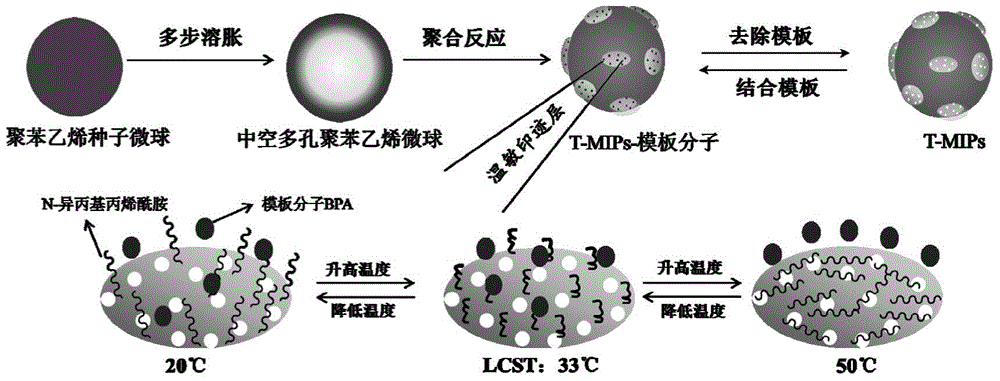

A technology of imprinted polymers and temperature-sensitive bisphenols, which is applied in the fields of materials science and engineering and environmental science, can solve the problems that the recognition performance is difficult to fully exert, the BPA adsorption capacity is small, and there is no good carrier load, etc., to achieve good solution temperature response, Improve the adsorption capacity, the effect of simple and novel principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

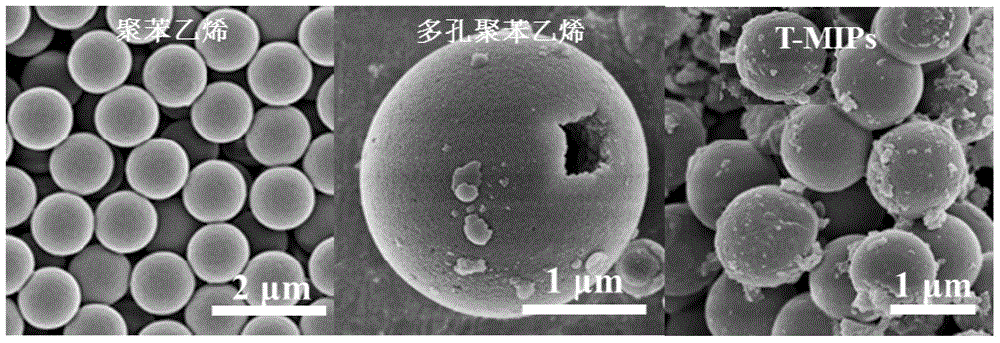

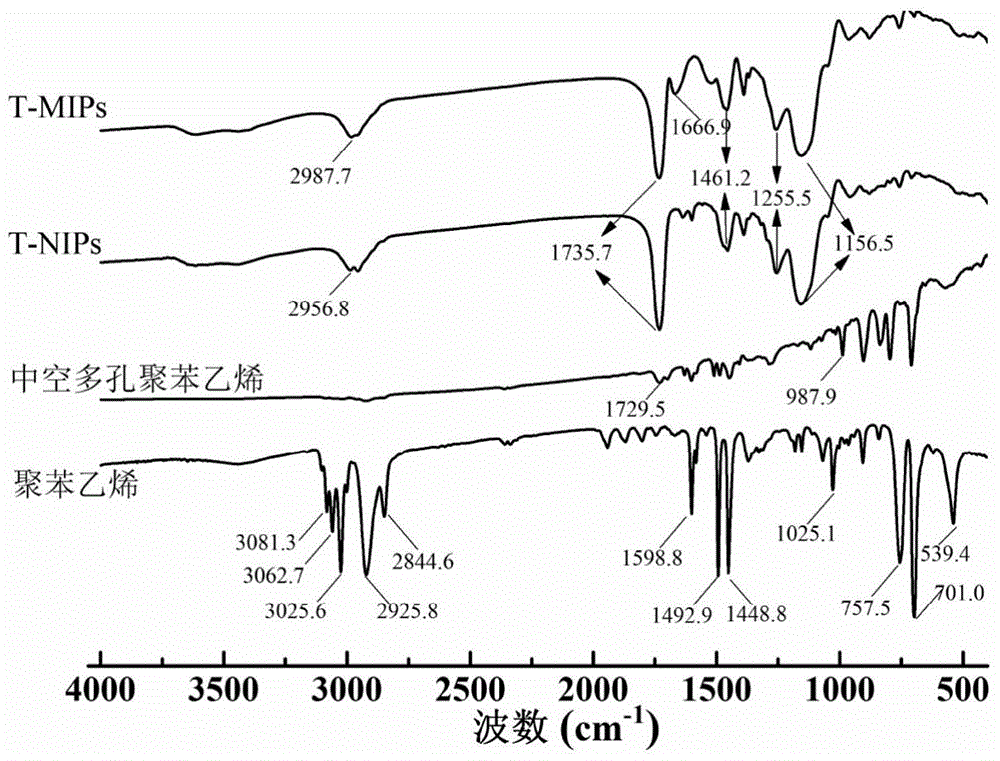

[0031]a. Synthesis of polystyrene seed microspheres: Add 100mL of absolute ethanol, 20mL of deionized water and 0.7g of polyvinylpyrrolidone into a 250mL three-neck flask, then disperse them evenly by ultrasonic and constant stirring, and then slowly add 5mL Styrene was blown under nitrogen for 30 minutes, then 40 mg of azobisisobutyronitrile was added, and the temperature of the mixed solution was raised to 60° C. and maintained, and then polymerized under nitrogen protection for 24 hours. The obtained polystyrene microsphere product was washed successively with deionized water and absolute ethanol six times respectively, and the obtained product was vacuum-dried at 40° C. to constant weight, and collected for future use.

[0032] b. Synthesis of hollow porous polystyrene microspheres: Add 0.125g of sodium dodecylsulfonate and 50mL of deionized water into a 100mL two-necked flask, shake until completely dissolved and add 0.2g of the polystyrene synthesized above Seeds, consta...

Embodiment 2

[0040] Weighed 20 mg of T-MIPs and T-NIPs samples respectively, placed them in six 10 mL test tubes with ground stoppers, and added 2 mL of BPA and its five structural analogues (β-estradiol , estriol, estrone, cholesterol and phenol) in acetonitrile solution, shaking at room temperature for 24h. Then the mixture was centrifuged, filtered with a 0.45 μm microporous membrane, and the concentration of BPA and its structural analogues in the filtrate was measured by HPLC-UV, and the imprinted products were calculated accordingly. The adsorption capacity was measured 3 times in parallel for each experiment. As a control, 20 mg of T-NIPs was weighed for the same experiment. The result is as Figure 4 As shown, the adsorption capacity of T-MIPs to BPA was significantly higher than that of the other 5 kinds of phenolic substances, indicating that there were specific sites in T-MIPs and had high selectivity to BPA; There is no significant difference in the adsorption capacity of th...

Embodiment 3

[0042] Weigh 10 mg of T-MIPs and T-NIPs samples respectively, add them to 2.0 mL of solutions containing different concentrations of BPA (1, 10, 30, 50, 100 mg / L), place them in 5 mL stoppered glass test tubes, and transfer them immediately Put it into constant temperature water baths at 20, 33 and 50°C, after 24 hours of full adsorption, quickly filter and centrifuge, and filter with a 0.45 μm microporous membrane, the BPA concentration in the filtrate is quantified by HPLC-UV, and the three temperatures are evaluated The change of BPA adsorption capacity of imprinted polymer. Each group of experiments was measured 3 times in parallel. The result is as Figure 5 As shown, the adsorption of T-MIPs and T-NIPs to different concentrations of BPA has a certain response to the temperature change; at the lower critical temperature (LCST) of 33 °C, T-MIPs has the best adsorption effect on template molecules , indicating that the imprinted polymer layer is in a stretched state; at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com