Quantum dot material having inorganic ligand as well as preparation and application of quantum dot material

A technology of quantum dot materials and inorganic ligands, which is applied to quantum dot materials with inorganic ligands and their preparation and application fields, can solve problems such as dispersibility and luminescence quantum efficiency, and achieves convenient operation, low turn-on voltage, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

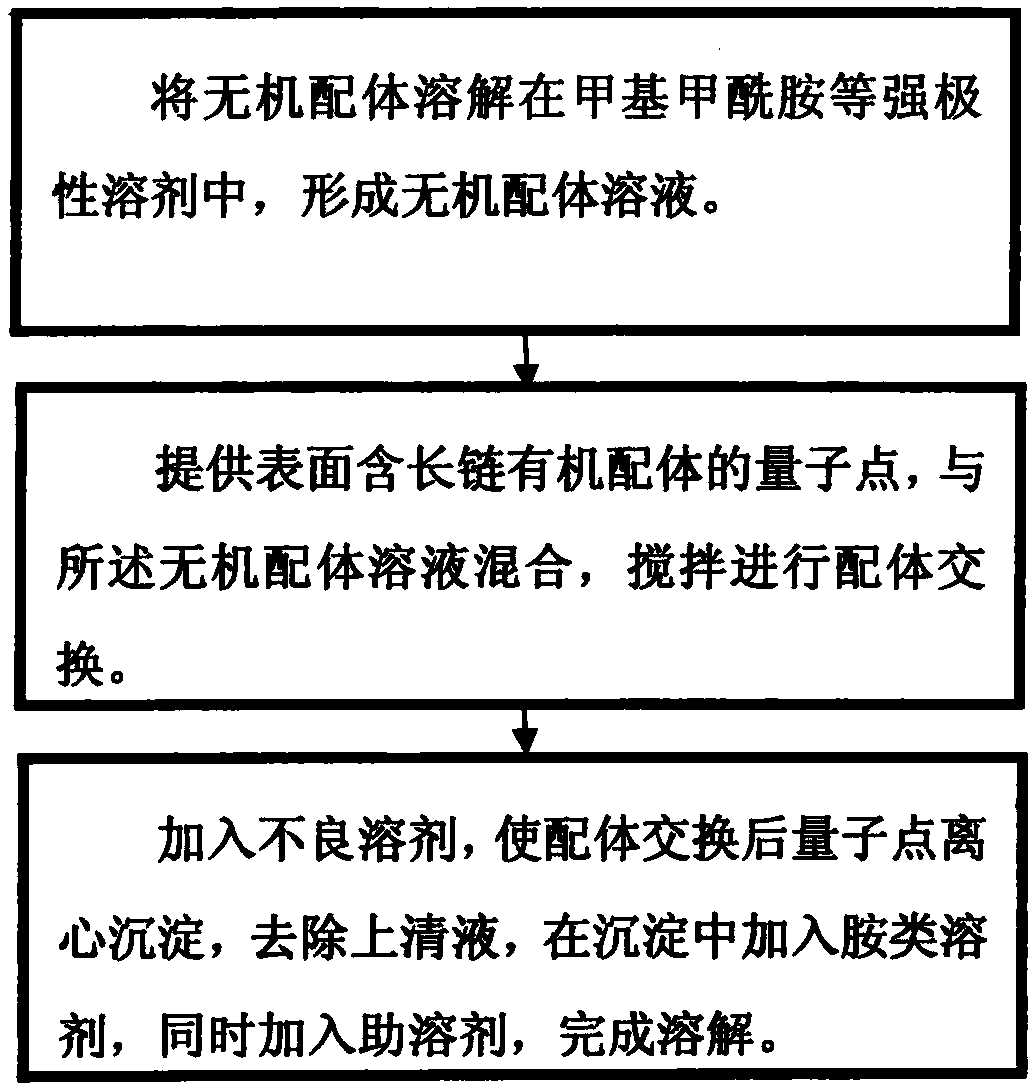

[0039] A quantum dot material with inorganic ligands, the preparation method of which is:

[0040] Take 56 mg of potassium hydroxide, add 10 mL of methylformamide solvent, stir and dissolve to form an inorganic ligand solution. 20 mg of green light CdSe / ZnS quantum dots of oleic acid ligand and 10 mL of n-hexane were mixed with the inorganic ligand solution, stirred at room temperature and air for 10 minutes for ligand exchange; the upper layer of n-hexane for ligand exchange was removed, Another 10 mL of n-hexane was added, stirred for 10 minutes, and this removal-addition process was repeated 3 times.

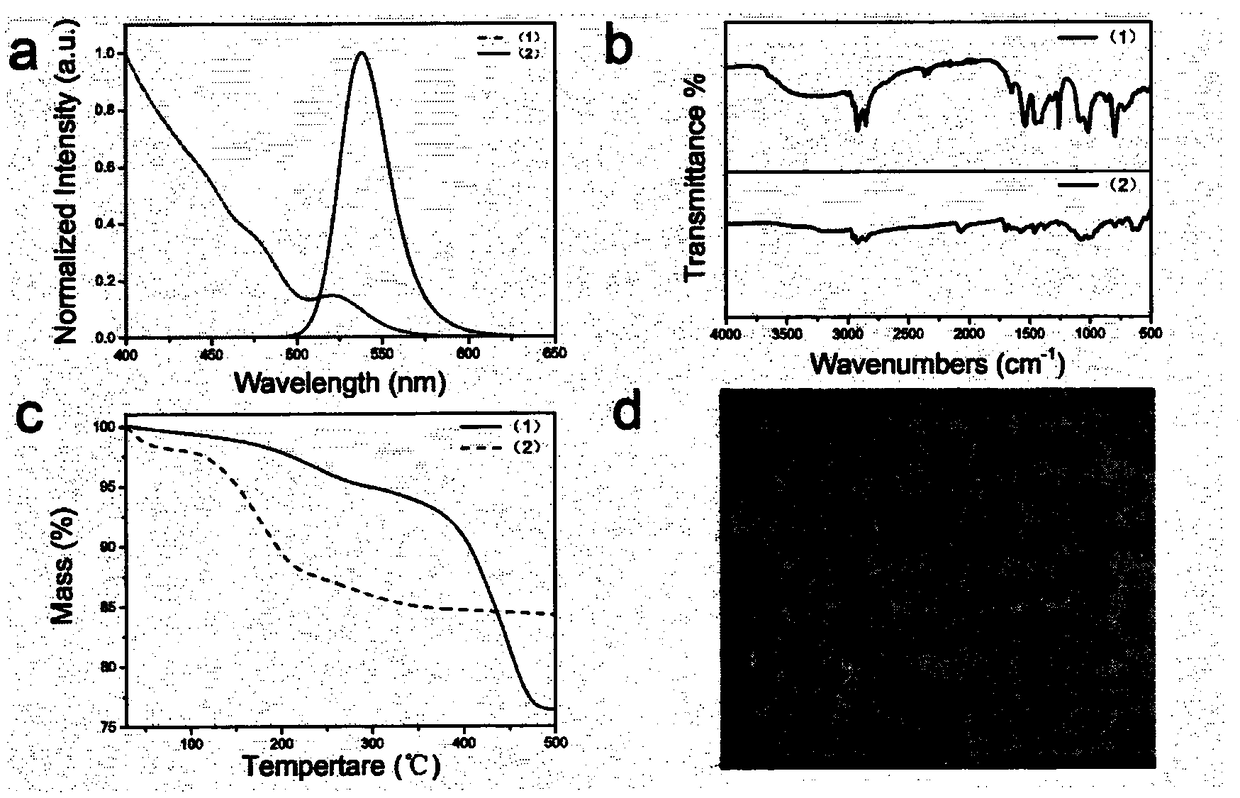

[0041] Then add 20mL acetonitrile to precipitate the quantum dots after ligand exchange, centrifuge, remove the supernatant, add 1mL butylamine to the precipitate, and add 20uL ammonium sulfide solution with a concentration of 20% as a cosolvent at the same time, complete the dissolution, and obtain body quantum dots. Its infrared spectrum is as figure 2 As shown in b(2),...

Embodiment 2

[0045] Such as Figure 5 Shown, a kind of photoluminescence device comprises the conductive glass with hole transport layer material, is provided with the quantum dot material with inorganic ligand described in embodiment 1 on the hole transport layer material of conductive glass, has inorganic Electron transport layer materials and metal electrodes are sequentially deposited on the quantum dot material of the ligand.

[0046] The preparation method of above-mentioned photoluminescence device is:

[0047] Step a: Prepare a nickel oxide film (NiO film) as a hole transport layer on a clean conductive ITO glass substrate. The preparation method is: add ethylenediamine and ethylene glycol to nickel nitrate hexahydrate and stir at 70 ° C The NiO precursor solution was formed in 3 hours, and the molar ratio of the three compounds was 1:1:1. The NiO precursor solution was spin-coated on a clean conductive ITO glass substrate, and sintered in a muffle furnace at 300°C for 60min to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com