Preparation method of bioactive glass-wrapping modified zirconium oxide dental ceramic material

A technology of bioactive glass and dental ceramics, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of low interfacial bonding force, decreased mechanical strength of ceramics, uncertain effect, etc., to promote proliferation and osteogenic differentiation. , Improve the effect of repairing, improve the biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

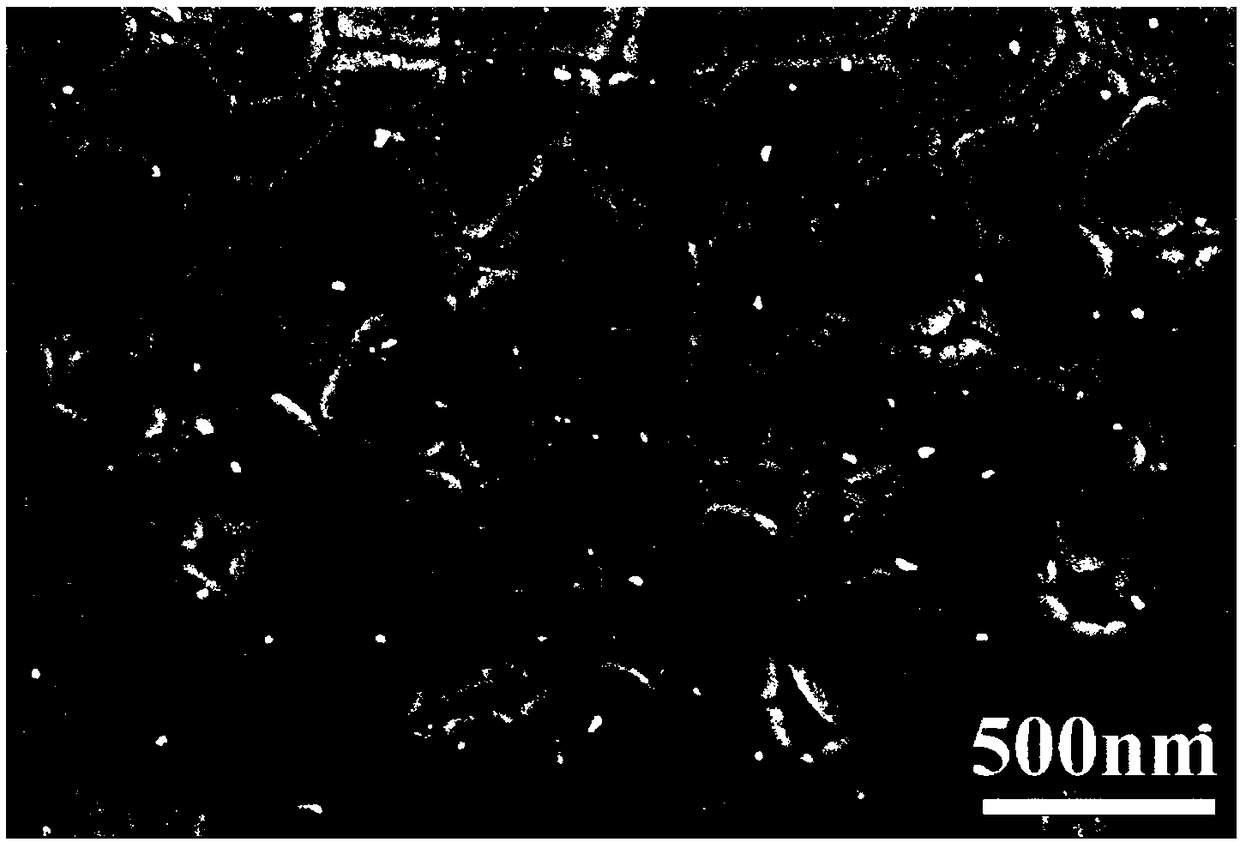

[0050] The application composition of this embodiment is SiO 2 ,40mol%; CaO,56mol%; P 2 o 5 , 4mol% bioactive glass to improve the bioactivity of yttrium partially stabilized tetragonal zirconia ceramics (Y-TZP), the specific process includes:

[0051] (1) According to the composition ratio, tetraethyl orthosilicate (TEOS, Si(OC 2 h 5 ) 4 )) dissolved in deionized water (orthosilicate: deionized water molar ratio is 1:4), add 0.1mol / L of HNO 3 Adjust the pH to 1.67, stir with a mixer at a speed of 250r / min, and the stirring time is 60min;

[0052] (2) After observing that the solution in step (1) becomes clear, add triethyl phosphate (TEP, OP(OC 2 H5) 3 ), stirring at a speed of 250r / min, the stirring time is 60min;

[0053] (3) after the solution of observation step (2) becomes clear, add calcium nitrate (Ca(NO 3 ) 2 4H 2 (0), stirring at a speed of 250r / min, the stirring time is 60min;

[0054] (4) Obtain the bioactive glass precursor sol after the solution in th...

Embodiment 2

[0070] The application composition of this embodiment is SiO 2 ,90mol%; CaO,18mol%; P 2 o 5 ,1mol% bioactive glass to improve the bioactivity of magnesium partially stabilized tetragonal zirconia ceramics (Mg-TZP), the specific process includes:

[0071] (1) According to the composition ratio, tetraethyl orthosilicate (TEOS, Si(OC 2 h 5 ) 4 )), dissolved in deionized water (orthosilicate: deionized water molar ratio is 1:12), adding 0.1mol / L of HNO 3 Adjust the pH to 6, stir with a mixer at a speed of 1000r / min, and the stirring time is 50min;

[0072] (2) After observing that the solution in step (1) becomes clear, triethyl phosphate (TEP, OP(OC) 2 H5) 3 ), stirring at a speed of 1000r / min, the stirring time is 50min;

[0073] (3) After the solution of observation step (2) becomes clear, the calcium nitrate (Ca(NO) added in according to the composition ratio 3 ) 2 4H 2 (0), stirring at a speed of 250r / min, the stirring time is 50min;

[0074] (4) Obtain the bioact...

Embodiment 3

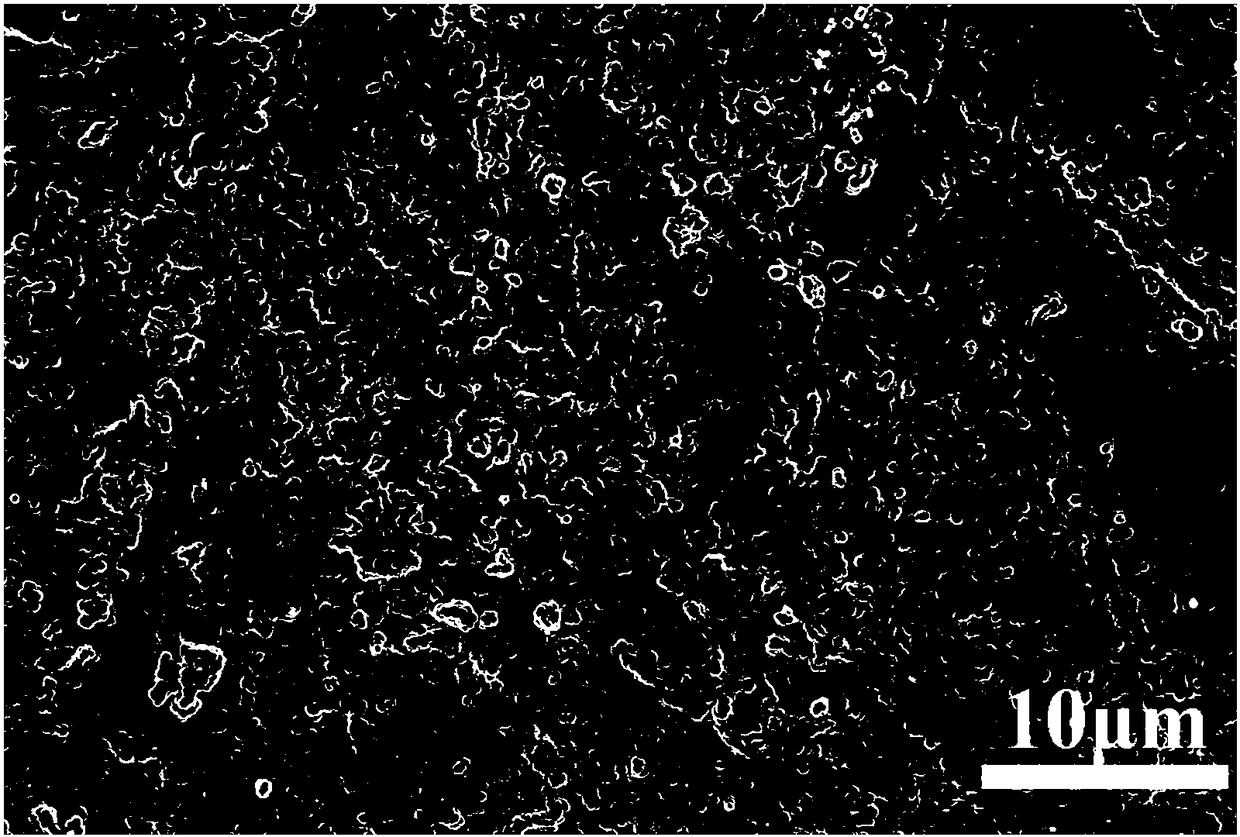

[0084] The application composition of this embodiment is SiO 2 , 65mol%; CaO, 33.5mol%; P 2 o 5 , 1.5mol% bioactive glass to improve the bioactivity of aluminum-toughened tetragonal zirconia ceramics (Al-TZP), the specific process includes:

[0085] (1) According to the composition ratio, tetraethyl orthosilicate (TEOS, Si(OC 2 h 5 ) 4 )), dissolved in deionized water (orthosilicate: deionized water molar ratio is 1:10), adding 0.1mol / L of HNO 3 Adjust the pH to 14, stir with a mixer at a speed of 800r / min, and the stirring time is 30min;

[0086] (2) After observing that the solution in step (1) becomes clear, triethyl phosphate (TEP, OP(OC) 2 H5) 3 ), stirred at a speed of 800r / min, and the stirring time was 30min;

[0087] (3) After the solution of observation step (2) becomes clear, the calcium nitrate (Ca(NO) added in according to the composition ratio 3 ) 2 4H 2 (0), stirring at a speed of 800r / min, the stirring time is 30min;

[0088] (4) Obtain the bioactiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com