Cement-based polymer mortar specially used for repairing and preparation method of mortar

A polymer, cement-based technology, applied in the field of construction mortar, can solve the problems of lack of uniform testing and evaluation methods and standards, affecting the development and market stability of repair mortar, hindering the benign development of products, etc., to improve volume stability, and ease of use. The effect of stable and excellent performance and guaranteed structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

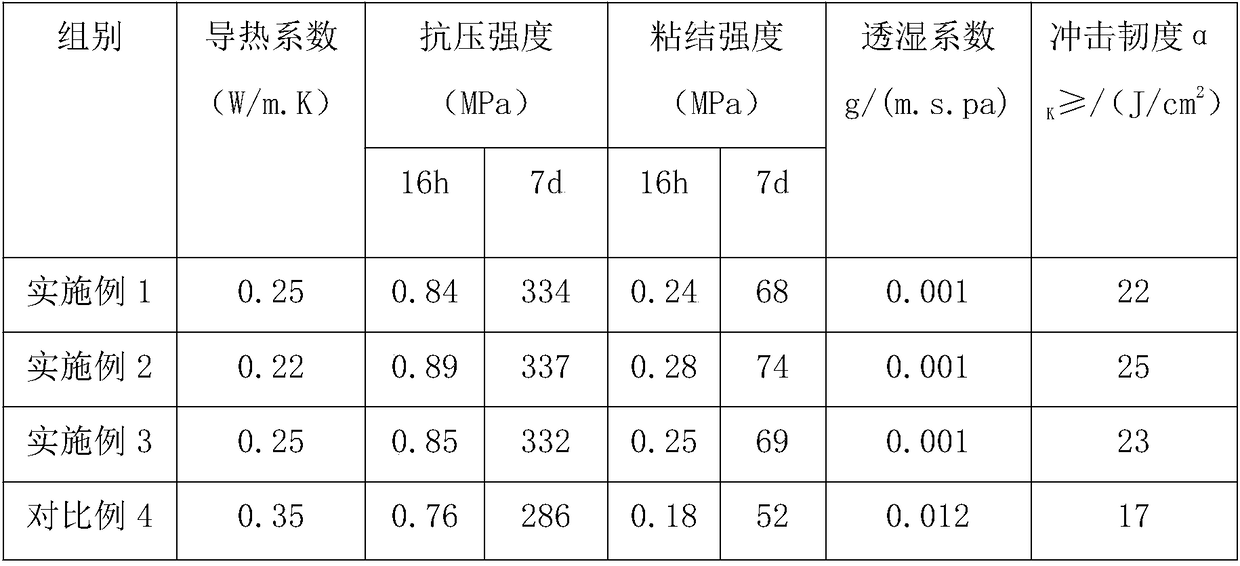

Examples

Embodiment 1

[0032] A special cement-based polymer mortar for repair, the following raw materials are obtained: 70kg of Wudalianchi volcanic mud, 20kg of modified composite mineral powder, 10kg of phosphogypsum slag, 4kg of sodium-based bentonite, 2kg of diabase fiber (fiber length is 600μm, aspect ratio 10), aminopropyltriethoxysilane 0.8kg, silicone resin polyether emulsion 3kg, sodium tripolyphosphate 0.4kg, polyacrylamide 0.2kg, calcium chloride 0.5kg, adhesion aid 1kg, water reducer : calcium lignosulfonate 0.8kg, foaming agent: microsphere foaming agent 2kg and anti-radiation agent: ferrocene 1kg;

[0033] Some raw materials are prepared by the following steps:

[0034] (1) Preparation of modified composite mineral powder:

[0035] Step 1: Obtain the following ingredients: 10kg of serpentine, 10kg of clinoptilolite, 15kg of hydrogen peroxide with a mass concentration of 20%, 0.6kg of potassium hydrogen phosphate, and 0.8kg of aminosilane coupling agent KH-5500.8kg;

[0036] Step 2:...

Embodiment 2

[0046] A special cement-based polymer mortar for repair, the following raw materials are obtained: 75kg of Wudalianchi volcanic mud, 20-25kg of modified composite mineral powder, 15kg of phosphogypsum slag, 5kg of sodium-based bentonite, 2.5kg of diabase fiber (the fiber length is 700μm, The aspect ratio is 11), aminopropyl triethoxysilane 1kg, silicone resin polyether emulsion 4kg, sodium tripolyphosphate 0.5kg, polyacrylamide 0.25kg, calcium chloride 0.6kg, adhesion aid 1.5kg, Water reducing agent: sodium sulfamate 0.9kg, foaming agent: ADC foaming agent 3kg and anti-radiation agent: ferrocene 1.25kg;

[0047] Some raw materials are prepared by the following steps:

[0048] (1) Preparation of modified composite mineral powder:

[0049] Step 1: Obtain the following ingredients: 11 kg of serpentine, 11 kg of clinoptilolite, 18 kg of hydrogen peroxide with a mass concentration of 25%, 0.7 kg of potassium hydrogen phosphate, and 1 kg of aminosilane coupling agent KH-5501;

[0...

Embodiment 3

[0060] A special cement-based polymer mortar for repair, the following raw materials are obtained: 80kg of Wudalianchi volcanic mud, 25kg of modified composite mineral powder, 20kg of phosphogypsum slag, 6kg of sodium bentonite, 3kg of diabase fiber (fiber length is 800μm, aspect ratio 12), aminopropyltriethoxysilane 1.2kg, silicone resin polyether emulsion 5kg, sodium tripolyphosphate 0.6kg, polyacrylamide 0.3kg, calcium chloride 0.7kg, adhesion aid 2kg, water reducer : calcium lignosulfonate 1.0kg, foaming agent: OBSH foaming agent 4kg and anti-radiation agent: ferrocene 1.5kg;

[0061] Some raw materials are prepared by the following steps:

[0062] (1) Preparation of modified composite mineral powder:

[0063] Step 1: Obtain the following ingredients: 12 kg of serpentine, 12 kg of clinoptilolite, 20 kg of hydrogen peroxide with a mass concentration of 30%, 0.8 kg of potassium hydrogen phosphate, and 1.2 kg of aminosilane coupling agent KH-550;

[0064] Step 2: Calcinate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com