Preparing method for comb-shaped-polymer phase change energy storage material

A technology of phase-change energy storage materials and comb-like polymers, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low enthalpy, narrow application range, poor processability of phase-change materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a comb polymer energy storage phase change material, comprising the following steps:

[0035] The DMF is subjected to vacuum distillation to remove water by means of vacuum distillation to obtain DMF after water removal for subsequent use.

[0036] 1) 130ml distilled water, 0.18mol acrylonitrile, 0.12mol maleic anhydride, and 0.006mol catalyst A ammonium persulfate-sodium bisulfite, wherein, in the catalyst ammonium persulfate-sodium bisulfite system, ammonium persulfate and sodium bisulfite The molar ratio of sodium bisulfate was 9:1, reacted under nitrogen atmosphere, stirring, and 60°C for 3h, separated the reaction product by suction filtration, washed 3 times with distilled water and ethanol, and dried in a vacuum oven at 40°C to obtain Primary product polyacrylonitrile maleic anhydride;

[0037] 2) Under the condition of nitrogen protection, add 120ml of anhydrous DMF solvent into the three-necked flask, and then add polyacrylonitrile malei...

Embodiment 2~4

[0042] Only change the mol ratio of polyacrylonitrile maleic anhydride and n-stearyl alcohol in embodiment 1 step 2), as embodiment 2~4, list is as follows:

[0043] Example

Embodiment 5-10

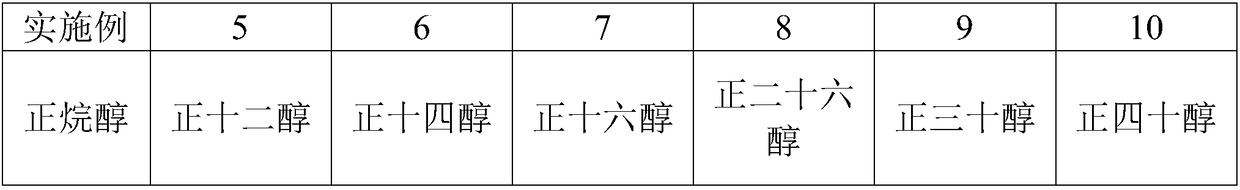

[0045] Only replace the n-stearyl alcohol that step 2) selects in embodiment 1) with different n-alkanols, as embodiment 5~10, list is as follows:

[0046]

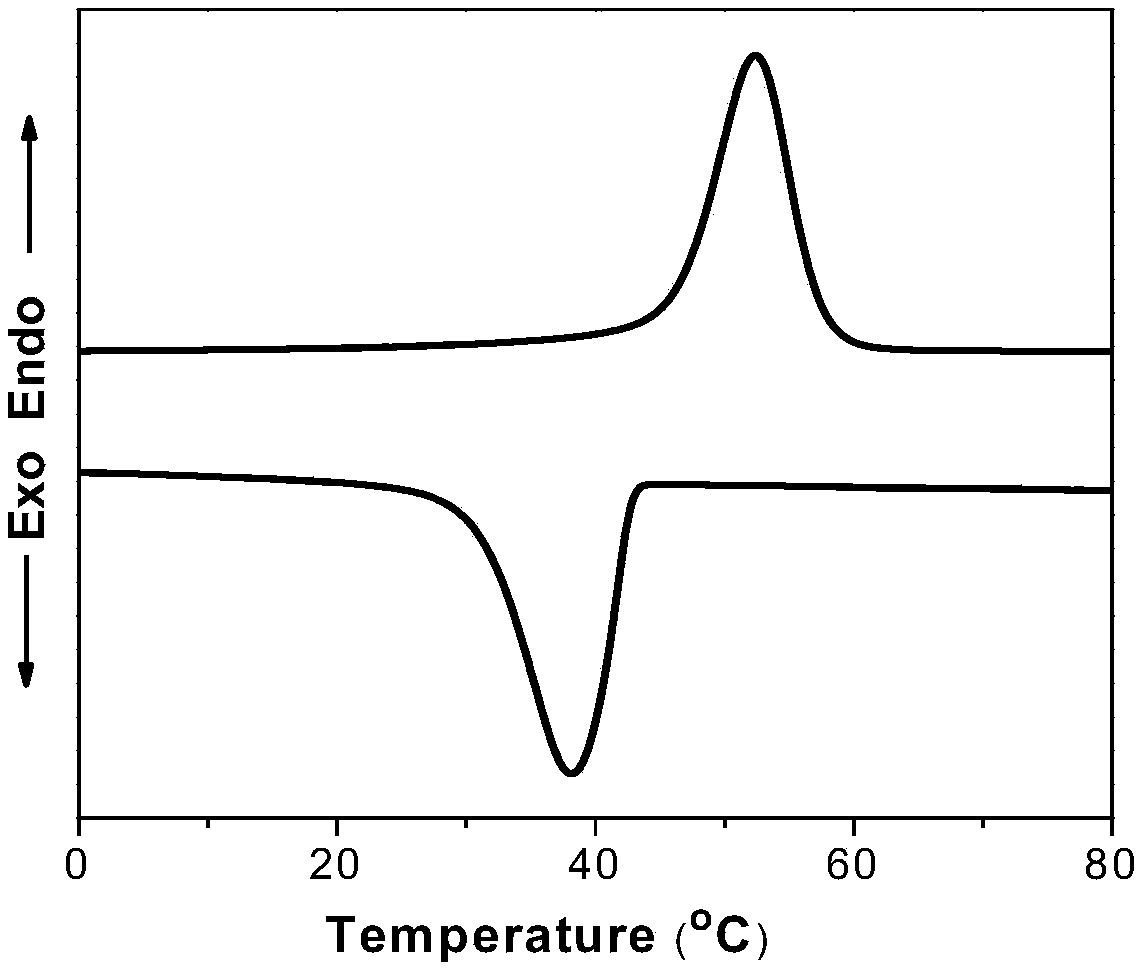

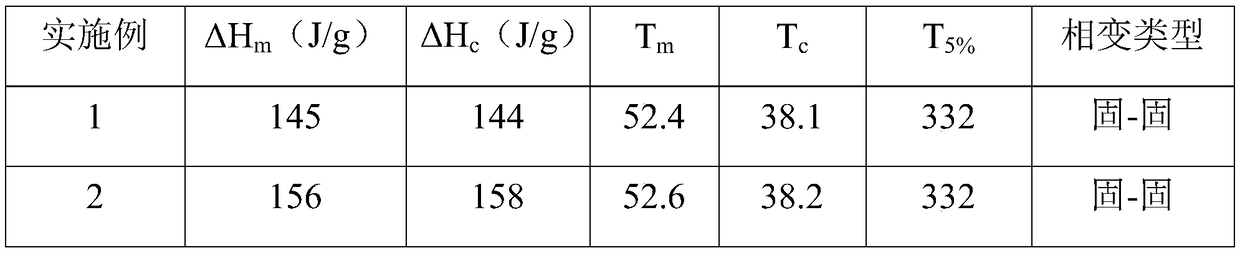

[0047]The performances of the comb polymer energy storage phase change materials prepared in Examples 2 to 10 were tested using the same test method as in Example 1, and the obtained data are shown in Table 1:

[0048] Table 1 Phase change properties of comb polymer energy storage phase change materials under different conditions

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Enthalpy | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com