A kind of method utilizing pvc pyrolysis to extract lithium from lepidolite

A lepidolite, lithium extraction technology, applied in the field of metallurgy, can solve the problems of shortening the chlorination roasting cycle, roasting temperature, limiting the comprehensive utilization of PVC, difficult storage and transportation, etc., to shorten the chlorination cycle, improve the chlorination efficiency, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

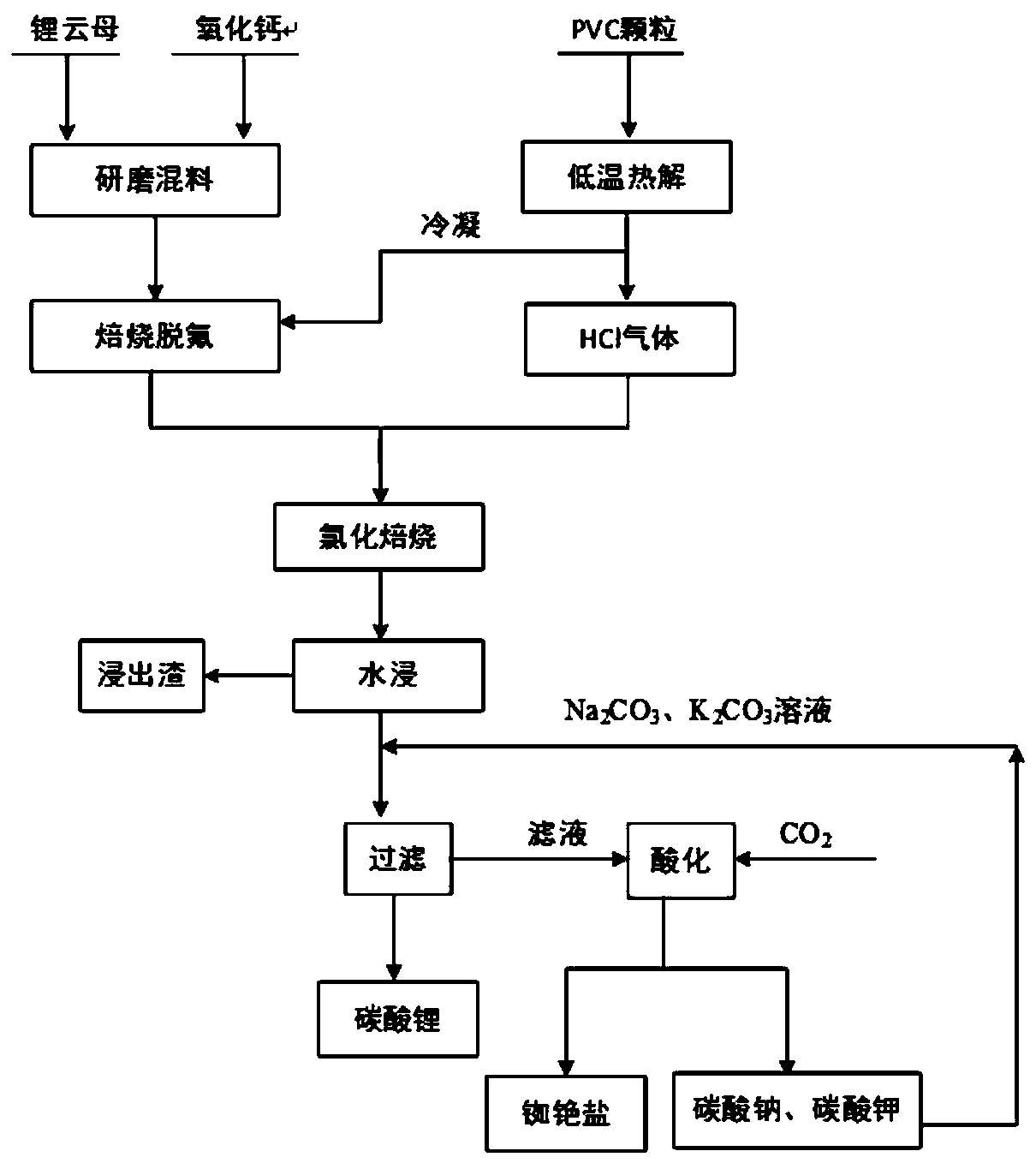

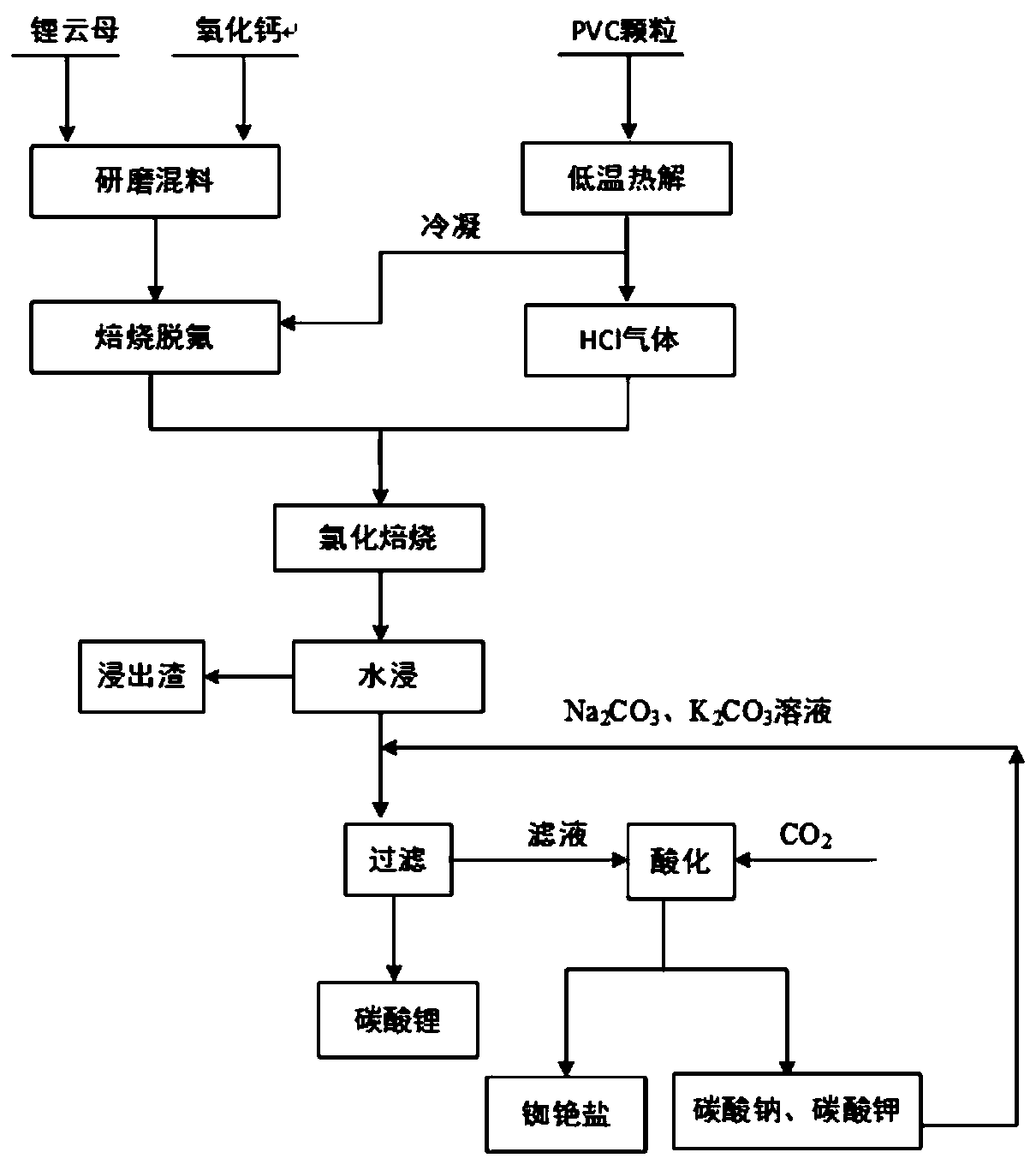

[0039] A method utilizing PVC pyrolysis to extract lithium from lepidolite, its process flow chart is as figure 1 shown, including the following steps:

[0040](1) Under a nitrogen atmosphere, crush the washed and dried PVC waste into plastic particles with a particle size of 5-10mm, and then place it in a pyrolysis furnace for low-temperature pyrolysis, and control the temperature of the pyrolysis treatment to 350°C , the heating rate is 5°C / min, the pyrolysis time is 1.5h, and HCl gas and tar are obtained;

[0041] (2) will Li 2 Lepidolite ore with an O content of 3.5% and calcium oxide are mixed according to a mass ratio of 1:0.2, ground evenly, and then placed in a roaster for defluorination roasting. The controlled temperature is 700 ° C, and the roasting time is 30 minutes to obtain defluorinated lepidolite mine;

[0042] (3) Pass the HCl gas after the step (1) into the defluorinated lepidolite ore after the step (2), carry out chlorination roasting, control the tempe...

Embodiment 2

[0049] A method utilizing PVC pyrolysis to extract lithium from lepidolite, its process flow chart is as figure 1 shown, including the following steps:

[0050] (1) Under an argon atmosphere, place the cleaned and dried PVC plastic particles in a pyrolysis furnace for low-temperature pyrolysis. The temperature of the pyrolysis treatment is controlled at 400°C, and the heating rate is 5°C / min. For 2h, HCl gas and tar were obtained;

[0051] (2) will Li 2 Lepidolite ore with an O content of 3.8% and calcium oxide are mixed according to a mass ratio of 1:0.3, ground evenly, and then placed in a roaster for defluorination and roasting. The temperature is controlled at 800 ° C, and the roasting time is 30 minutes to obtain defluorinated lepidolite. mine;

[0052] (3) Pass the HCl gas after the step (1) into the defluorinated lepidolite ore after the step (2), carry out chlorination roasting, control the temperature to be 350° C., and the roasting time is 2 hours to obtain clinke...

Embodiment 3

[0058] A method utilizing PVC pyrolysis to extract lithium from lepidolite, its process flow chart is as figure 1 shown, including the following steps:

[0059] (1) Under a nitrogen atmosphere, put the cleaned and dried PVC plastic particles in a pyrolysis furnace for low-temperature pyrolysis. The temperature of the pyrolysis treatment is controlled at 350°C, the heating rate is 8°C / min, and the pyrolysis time is 1h, get HCl gas and tar;

[0060] (2) will Li 2 Lepidolite ore with an O content of 4.5% and calcium oxide are mixed according to a mass ratio of 1:0.25, ground evenly, and then placed in a roaster for defluorination and roasting. The temperature is controlled at 750 ° C, and the roasting time is 30 minutes to obtain defluorinated lepidolite. mine;

[0061] (3) Pass the HCl gas after the step (1) into the defluorinated lepidolite ore after the step (2), carry out chlorination roasting, control the temperature to be 450°C, and the roasting time is 1h to obtain clin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com