Graphene composite aluminium oxide ceramic nano-filtration membrane, filter, and preparation method and application thereof

A technology of alumina ceramic membrane and alumina ceramic, which is applied in chemical instruments and methods, ceramic products, applications, etc., can solve the problems of polymer filtration membrane difficulties, unsatisfactory separation effect, and lack of uniform pore diameter of clear pore channels, etc., to achieve effective Intercept water molecules, clean separation, large flux effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

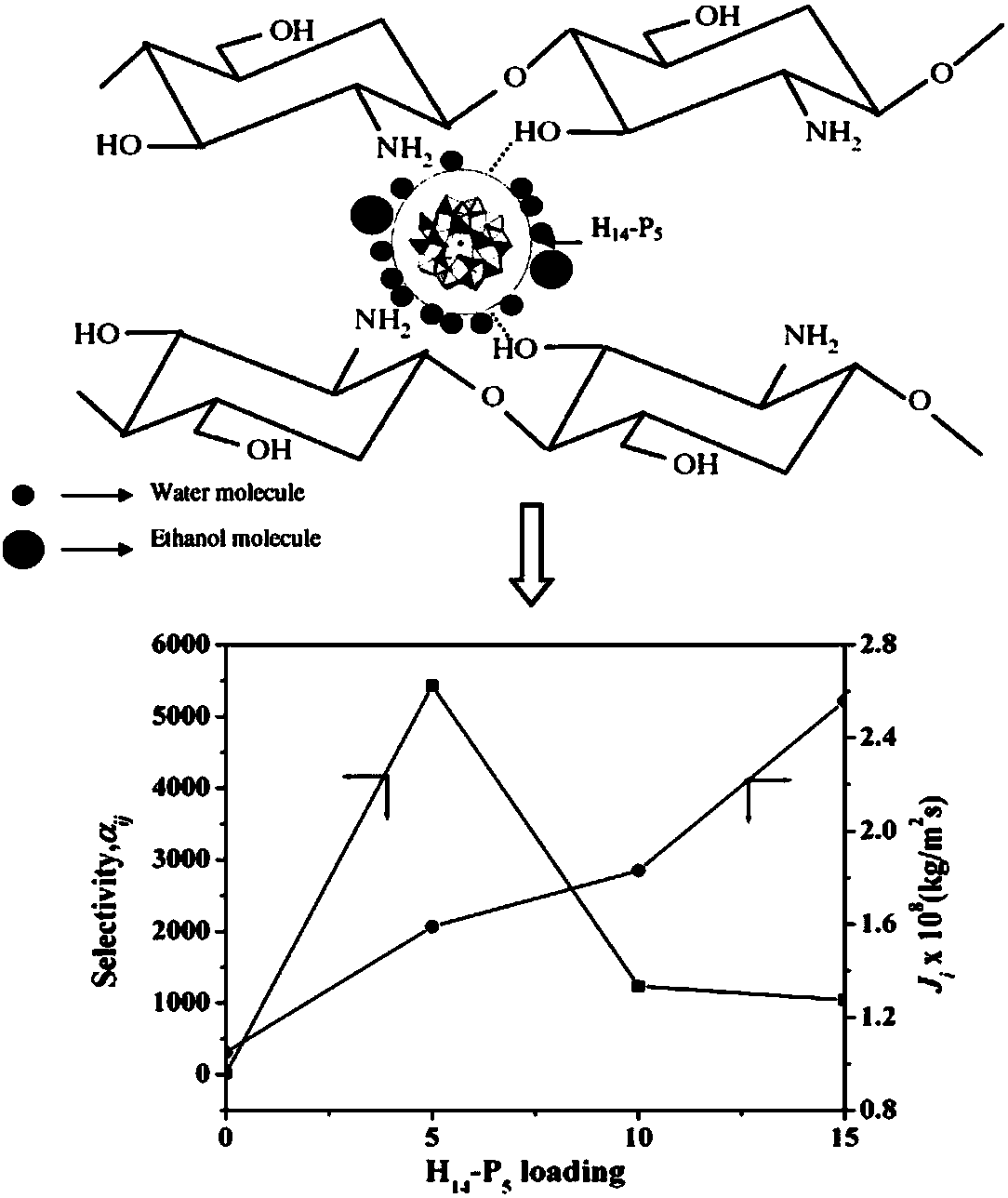

[0045] Graphene-alumina ceramic nanocomposite filtration membranes were prepared by chemical vapor deposition.

[0046] Put 0.5 g of silicone rubber and a tubular alumina ceramic membrane without any treatment into a tube furnace. The reactor was heated under argon with a heating rate of 1Ks -1 , the argon flow rate is 300 sccm. When the temperature rises to 873K, a certain amount of hydrogen gas (for example, 200 sccm) is introduced into the atmosphere, and the temperature is kept rising until the deposition temperature (including 1073 and 1273K) is reached. Keep the two kinds of gas flow and temperature conditions for a certain period of time (including 120s and 1200s), after the graphene growth is completed, the substrate is cooled to room temperature under argon and hydrogen conditions to obtain the graphene-alumina ceramic nanocomposite filter of the present invention membrane.

[0047] Figure 4 and Figure 5 It is the SEM figure of the nanocomposite filter membrane...

Embodiment 2

[0049] The thickness of the graphene growth is controlled by the quality of the silicone rubber. Specifically, by using the same method as in Example 1, only adjusting the amount of the silicone rubber, graphene layers with different thicknesses (500nm-1000nm) can be obtained as required.

Embodiment 3

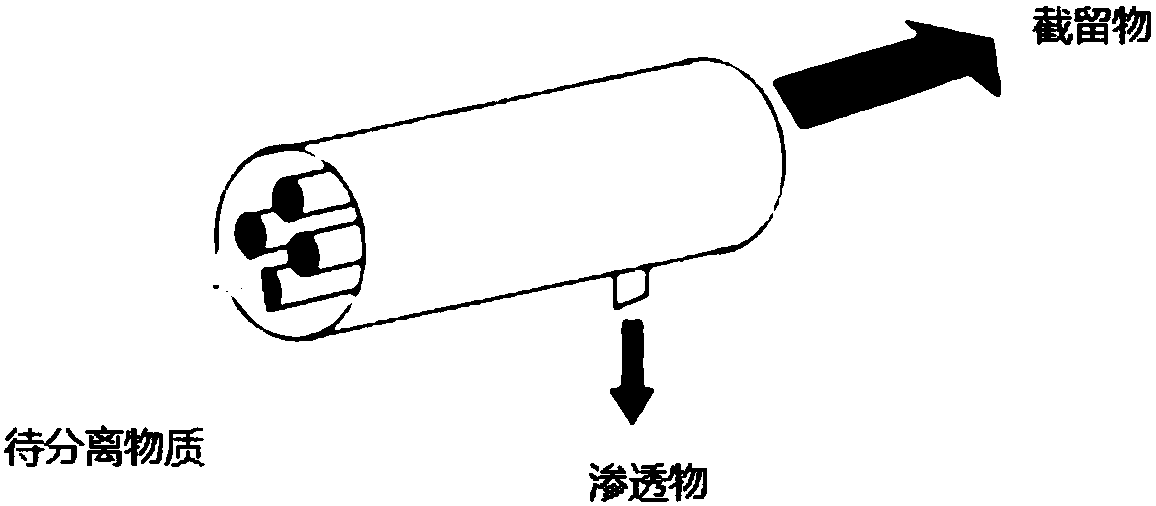

[0051] The graphene-alumina ceramic nanocomposite filtration membrane of embodiment 1-2 is used for the separation of ethanol and water, and the process of separation can be seen image 3 As shown, the separation effect reached about 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com