Precious metal aerogel and preparation method thereof

An aerogel and precious metal technology, applied in the field of precious metal aerogel and its preparation, can solve the problems of difficulty in obtaining nanoporous metals, fast reaction rate, etc., and achieve excellent application prospects, low cost, and good controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of Au airgel comprises the following steps:

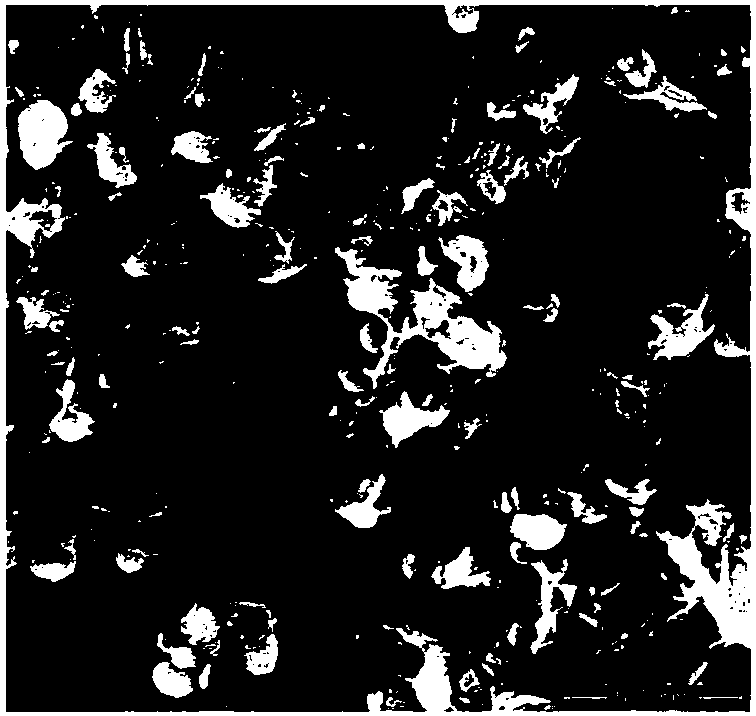

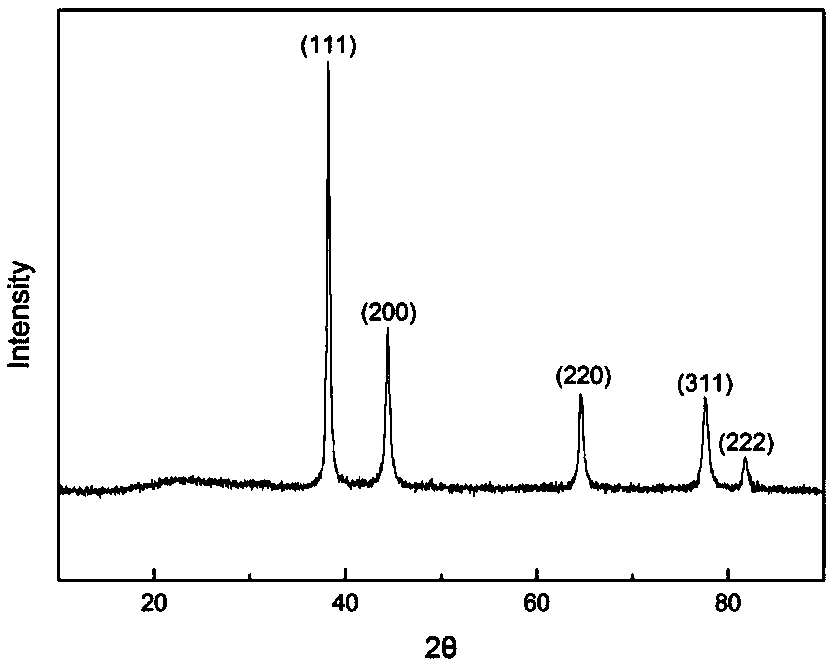

[0033] Step 1, prepare electroless nickel plating solution, take 0.2gNiCl 2 ·H 20, 5mL ethanol, 20mL deionized water, fully stir and dissolve to obtain a light green clear solution, then add 2mL ammonia water, 2mL hydrazine hydrate in turn; continue to stir to obtain an electroless nickel plating solution; use the sol-gel method to prepare evenly distributed Pd in the structure The wet gel of cellulose triacetate in the catalytic activation center is immersed in the prepared chemical nickel plating solution, and the chemical plating is performed once at room temperature, and the time of chemical plating is 24 hours; until the solution changes from blue to It becomes colorless, and Ni / cellulose triacetate composite airgel is obtained, which is placed in 0.01g / mL of HAuCl 4 Carry out displacement reaction in the solution, react at room temperature for 2 days, until the airgel is no longer magnetic, and obta...

Embodiment 2

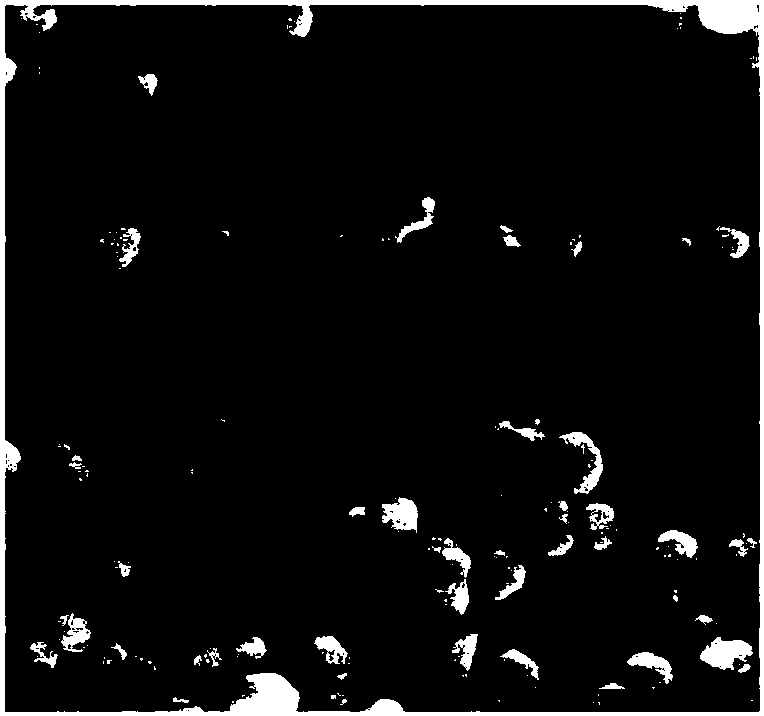

[0040] The preparation of Au airgel, according to the preparation process of the Au airgel described in implementation example 1, the difference is that the number of times of electroless Ni plating in the technical parameters is 2 times, each 24h, and each Ni plating amount is 0.2gNiCl 2 ·H 2 The content of Ni in the electroless plating solution of O, when the electroless plating solution changes from blue to colorless, replace the fresh plating solution; the specific surface area of the prepared Au airgel is 218.5m 2 / g, the average pore diameter is 9.45nm.

Embodiment 3

[0042] The preparation of Au airgel, according to the preparation process of the Au airgel described in implementation example 1, the difference is that the number of times of electroless Ni plating in the technical parameters is 3 times, each 24h, and each Ni plating amount is 0.2gNiCl 2 ·H 2 Ni content in the chemical plating solution of O, when the chemical plating solution changes from blue to colorless, replace the fresh plating solution. The prepared Au airgel has a specific surface area of 225.2m 2 / g, the average pore diameter is 9.35nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com