SiO2-BN composite ceramic and Invar alloy brazing method

A technology of composite ceramics and brazing method, which is applied in the direction of welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problems of unsatisfactory plastic deformation capacity and poor shear strength of welded joints, so as to improve mechanical properties, The effect of increasing plastic deformation capacity and relieving residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: this embodiment is a kind of SiO 2 -The brazing method of BN composite ceramics and Invar alloy is specifically completed according to the following steps:

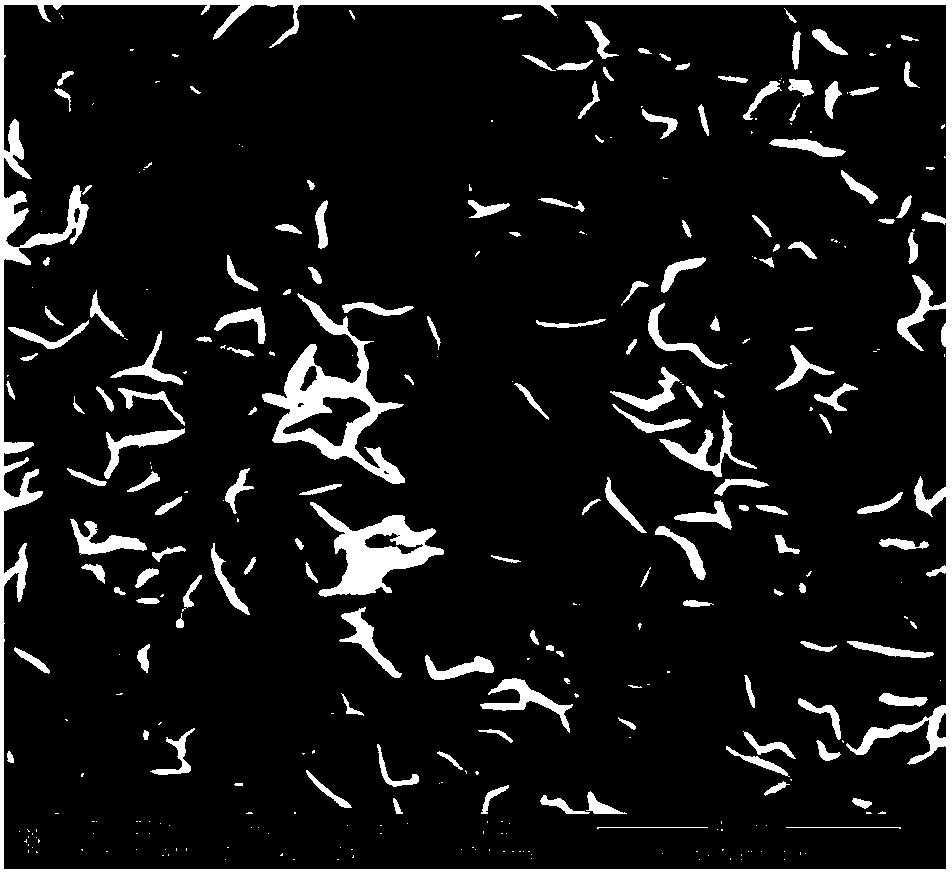

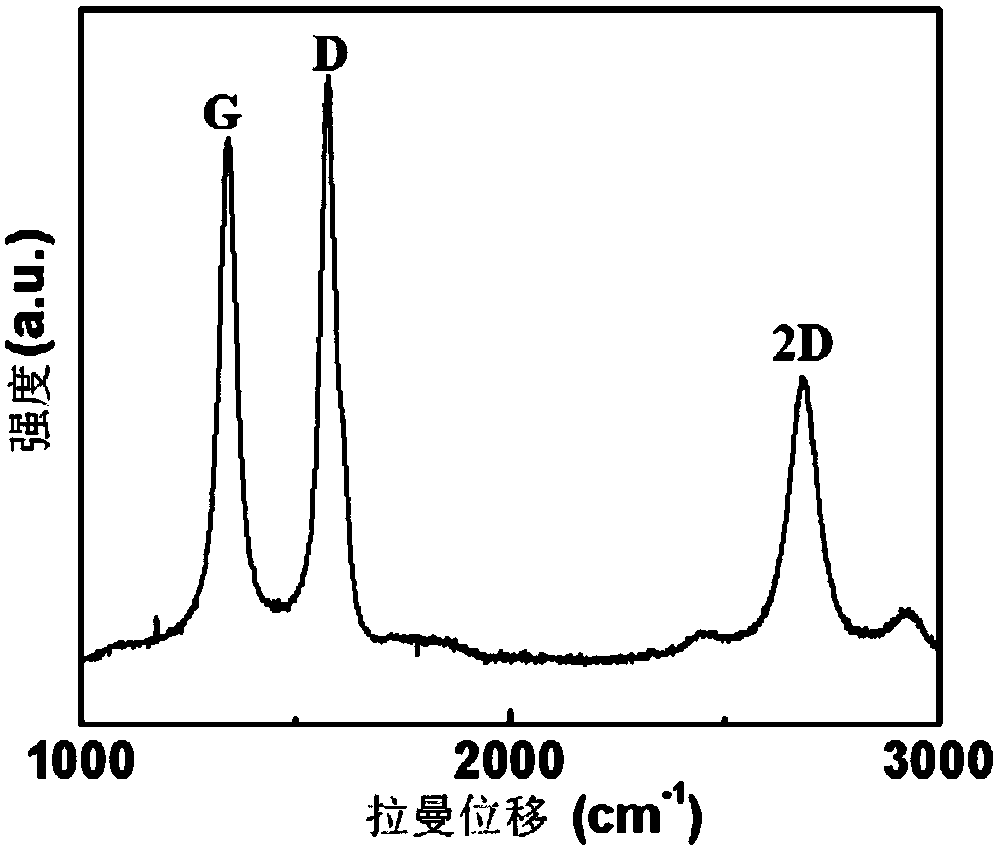

[0012] First, the graphene layer was grown vertically on the surface of the Invar alloy by plasma-enhanced chemical vapor deposition method, and then AgCuTi solder and SiO 2 -BN composite ceramic vacuum brazing.

[0013] As a new two-dimensional material, graphene has advantages that other materials cannot match: extremely high strength, excellent electrical conductivity, and extremely low resistivity, making it widely used in functional materials, material chemistry, supercapacitors and other fields. Now, in the field of material processing, especially in the field of welding, graphene has been successfully introduced into the welding process to play the role of its excellent properties. At present, experiments have proved that graphene can have a good affinity with active elements such ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the growth graphene layer on the surface of the Invar alloy is carried out according to the following steps:

[0017] 1. Pre-treatment: firstly grind the Invar alloy with sandpaper, ultrasonically clean it after grinding, and then polish it to obtain the polished Invar alloy, which is stored in acetone;

[0018] 2. Growth of graphene layer: ①. Place the polished Invar alloy on the workbench of the furnace cavity of the plasma-enhanced chemical vapor deposition vacuum device, and vacuum the furnace cavity to 10 -1 Below Pa, feed hydrogen gas at a flow rate of 40-50 sccm, adjust the pressure in the furnace chamber to 500 Pa, and then raise the temperature to 500-800 °C at a pressure of 500 Pa and a hydrogen flow rate of 40-50 sccm; ② Turn on the radio frequency power supply and adjust the radio frequency The power is 125W-200W, and the carbon source gas and argon gas are introd...

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the carbon source gas described in Step 2 ② and ③ is methane. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com