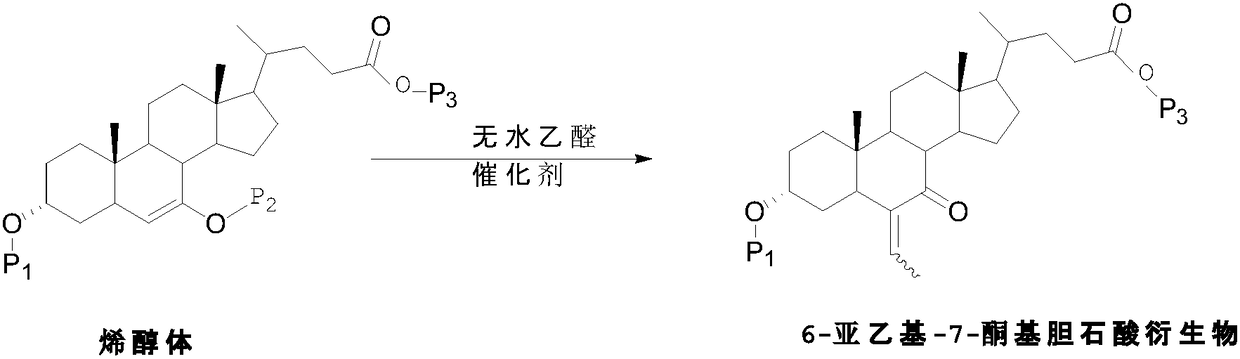

Method for producing 6-ethylidene chenodeoxycholic acid by continuous flow micro reactor

A technology of chenodeoxycholic acid and micro-reactor, which is applied in the field of production of 6-ethylene chenodeoxycholic acid, can solve the problems of increased side reactions, decreased product system purity, increased difficulties, etc., and achieves easy operation and control, Easy-to-sync amplification and simple post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

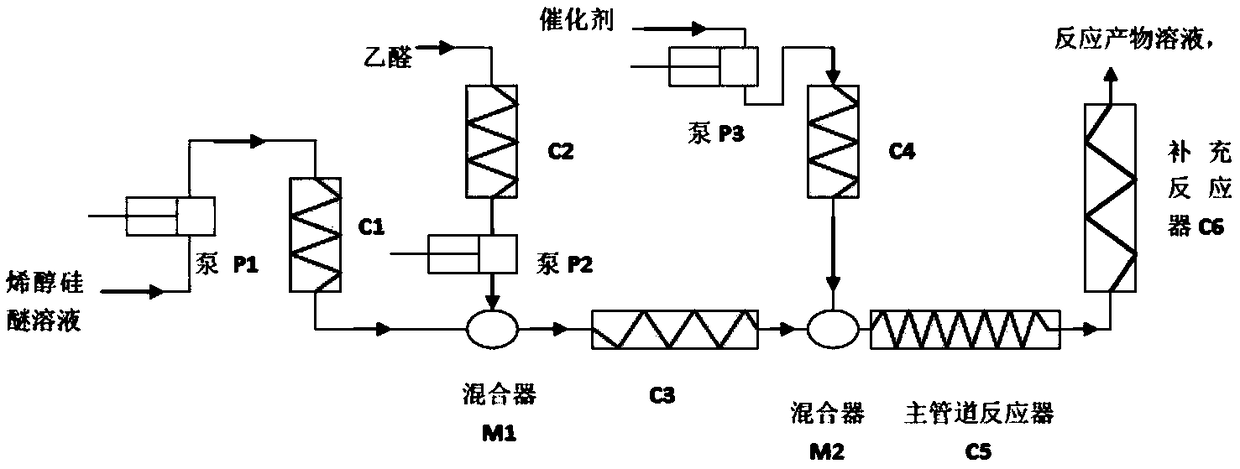

Method used

Image

Examples

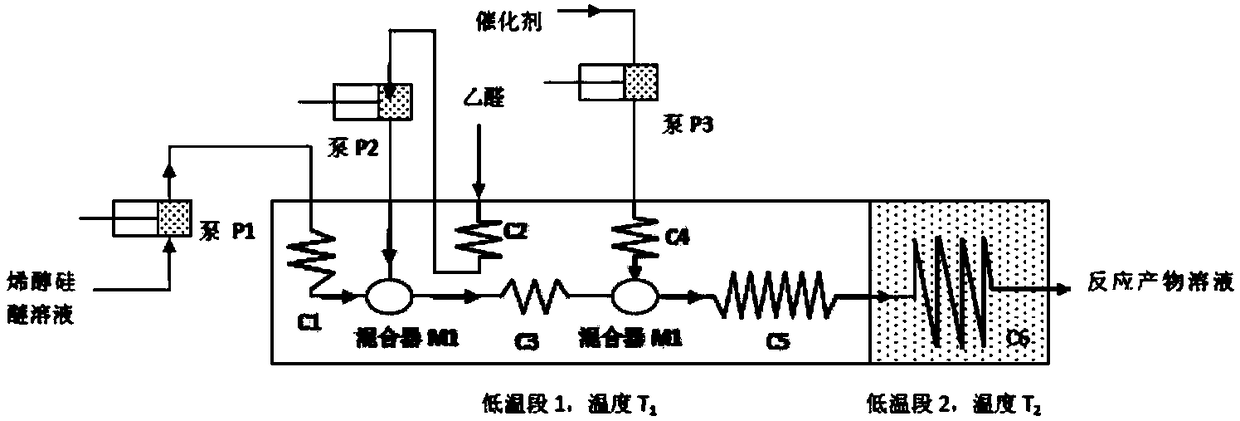

Embodiment 1

[0051] The cyclohexane solution of 0.5mol / L enol silyl ether S1, (274g S1 is dissolved in cyclohexane to make a total volume of 1 liter of cyclohexane solution), cooled to a solution temperature of about 0 degrees Celsius, passed The plunger pump P1 described in accompanying drawing 3 is pumped into a stainless steel pipe with an inner diameter of 0.2 mm, the linear velocity of the fluid in the pipe is 0.1-1 m / s, and the volume flow rate V1 is 3.14*10 - 8 m 3 / S, 1.84ml / min, Mol flow rate is 0.92mmol / min. This section of stainless steel pipe is immersed in a cold bath with a temperature of -35 degrees Celsius. The length of this section of pipe should ensure that the temperature of the fluid at the end of this section of pipe is lower than -30 degrees Celsius. Liquid anhydrous acetaldehyde flows through a stainless steel pipe immersed in a cold bath at -35 degrees Celsius, cooled to below -30 degrees Celsius, and then pumped into the pipeline reaction system through a plunge...

Embodiment 2

[0055] ingredients of each material. The sequence and flow process of flowing into the reactor are as in Example 1. Only the inner diameter of the main reaction mixing section and the main reaction section of the reactor is enlarged to 2mm. Keep the linear velocity of the fluid in the pipeline constant. The inner diameter of the reaction pipe in the supplementary reaction section is enlarged to 20mm. After the expansion of the reaction device, the cooling measures of each section should be appropriately strengthened, and the cooling bath should have a faster forced flow to ensure that the heat energy generated by the reaction in the pipeline can be exported in time.

[0056] It can produce about 40g of 6-ethylene chenodeoxycholic acid per minute, and can produce about 50Kg of 6-ethylene chenodeoxycholic acid per day in continuous operation. When the reactor is expanded to this specification, the impurities in the reaction system do not increase significantly.

Embodiment 3

[0058] Each material composition is consistent with Example 1, only the order of each material flowing into the reactor is changed: the boron trifluoride acetonitrile solution is first pumped in, after cooling, it is mixed with acetaldehyde in the mixer M1, and then in the high-efficiency mixer M2 is mixed with the cyclohexane solution of enol silyl ether, and the subsequent reaction and supplementary reaction process and temperature remain unchanged.

[0059] In this embodiment, the reaction mixture leaving the continuous flow reactor is clear and transparent, with very little impurity content, relatively simple post-treatment, and extremely high yield. A single set of reaction device can produce about 0.4g of 6-ethylene chenodeoxycholic acid per minute, and can produce about 50Kg of 6-ethylene chenodeoxycholic acid per day in continuous operation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com