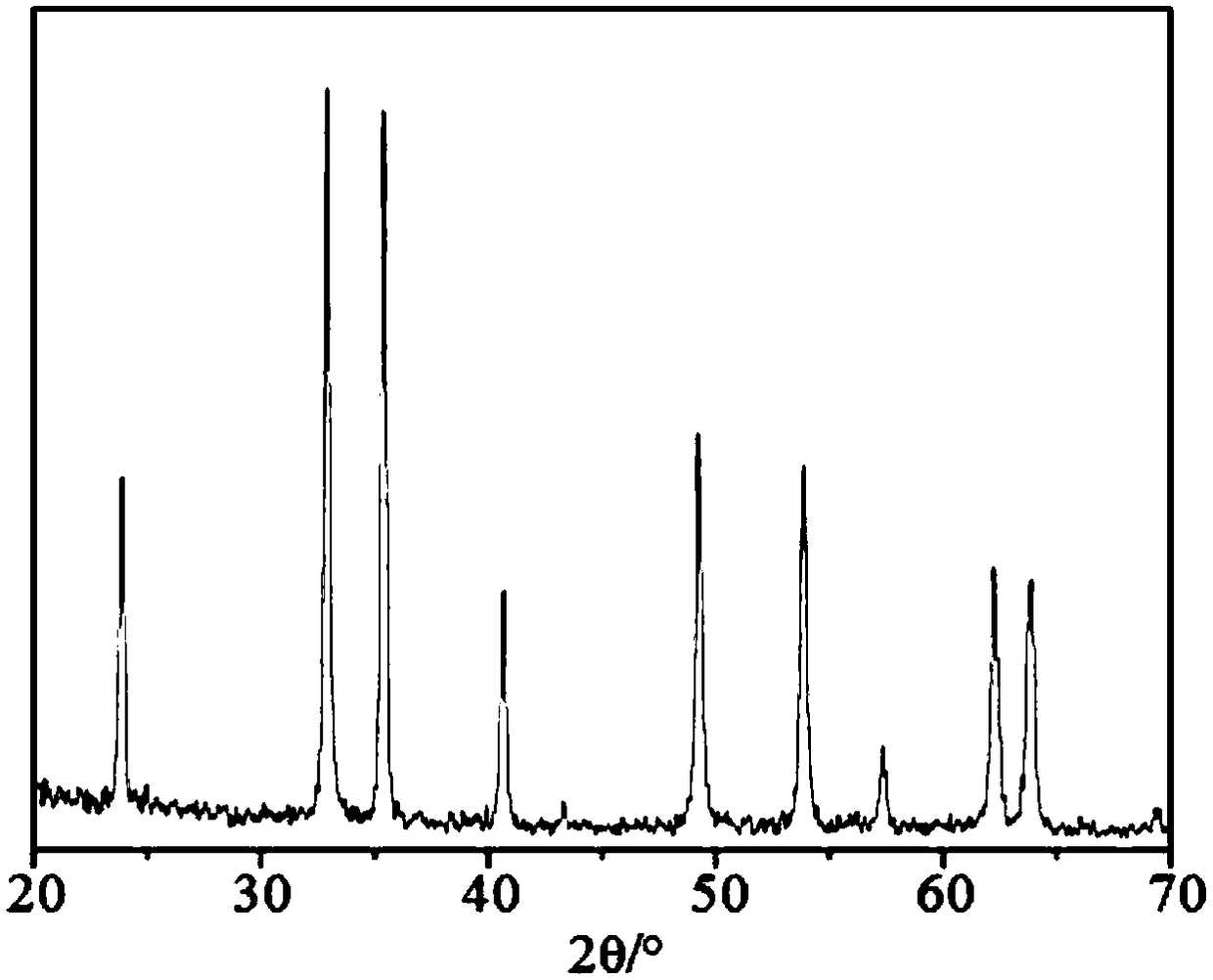

Preparation method of rhombohedral alpha type ferric oxide

A ferric oxide, rhombohedral technology, applied in the directions of iron oxide, iron oxide/iron hydroxide, etc., can solve the problem that it is difficult to prepare α-crystalline ferric oxide particles, and it is difficult to prepare α-crystalline ferric oxide particles. Iron particles and α-crystalline ferric oxide have not been reported, achieving the effects of large-scale industrial production, reduced preparation costs, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

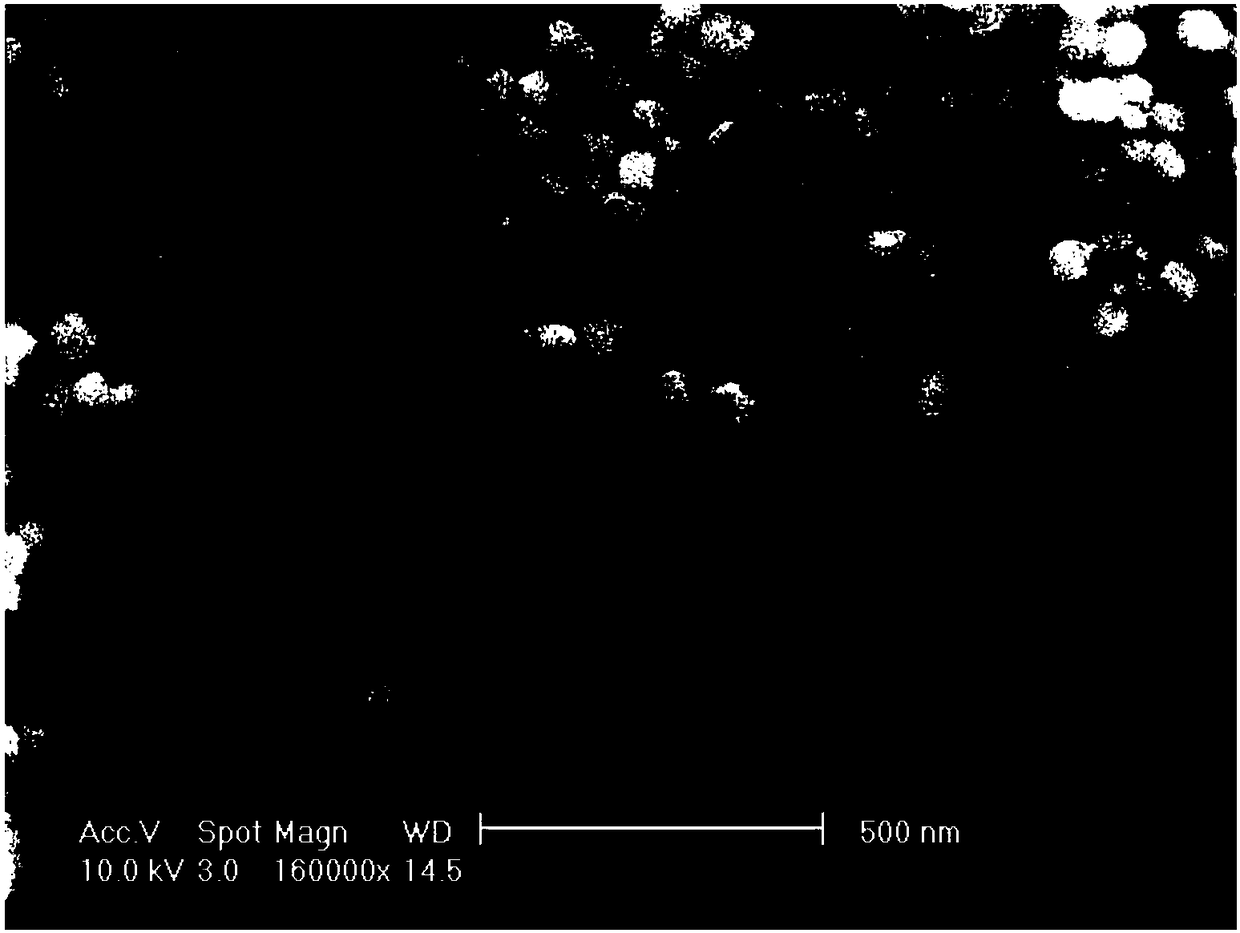

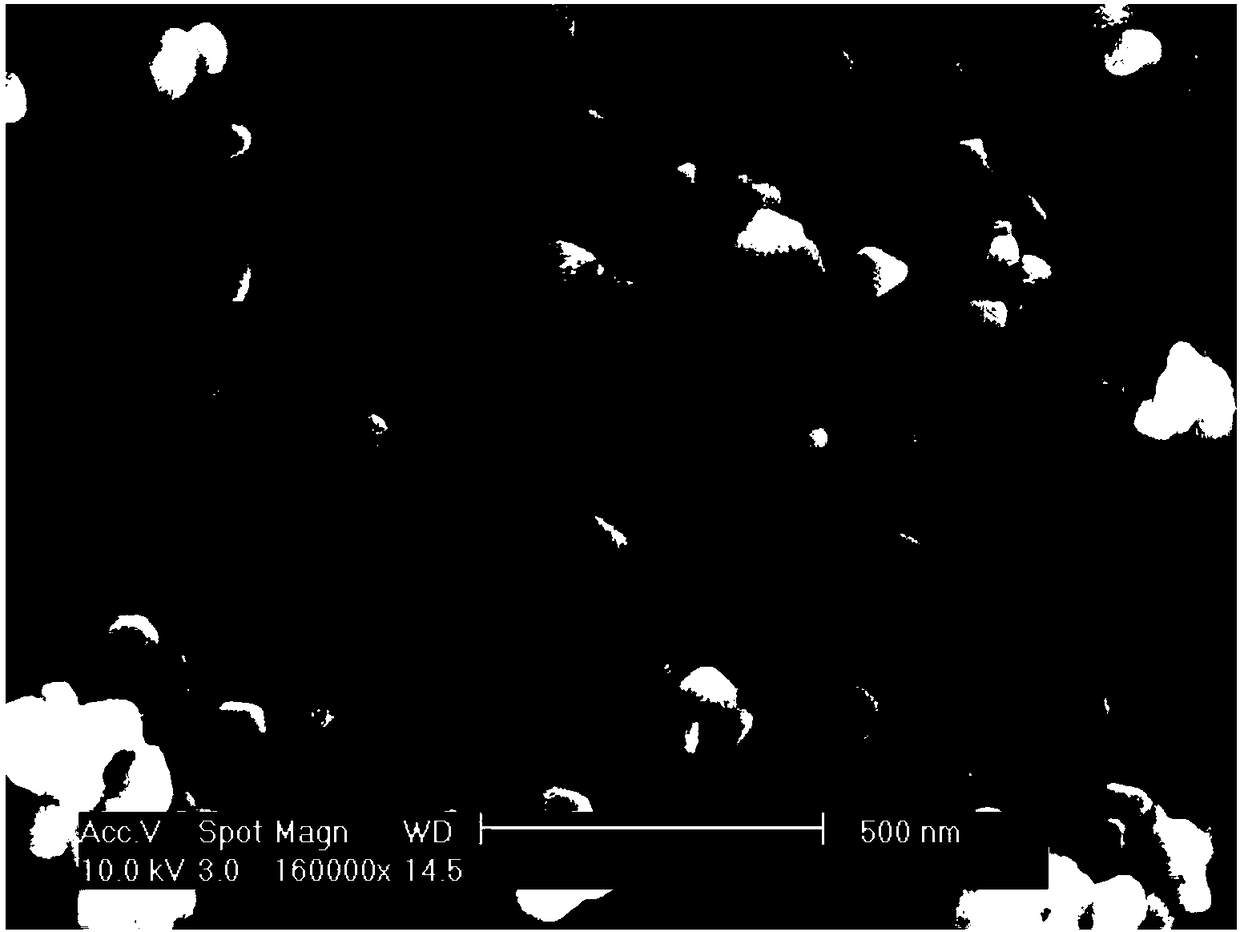

[0045] The invention discloses a preparation method of rhombohedral α-type ferric oxide; specifically, it comprises the following steps:

[0046] In step S1, a water-soluble iron salt solution is prepared.

[0047] Specifically, in the aqueous solution of the water-soluble iron salt, the molar concentration of the water-soluble iron salt is 0.013mol / L˜0.062mol / L.

[0048]Taking a 100mL reaction vessel as an example, 0.3g to 1.0g of water-soluble iron salt is dissolved in 60mL to 80mL of deionized water, and stirred evenly by magnetic force to obtain an aqueous solution of water-soluble iron salt.

[0049] Wherein, the water-soluble iron salt is at least one selected from ferric chloride hexahydrate, ferric chloride anhydrous, ferric sulfate anhydrous, ferric sulfate heptahydrate, ferric nitrate anhydrous, and ferric nitrate nonahydrate.

[0050] In step S2, adding phosphine organic substances to the water-soluble iron salt solution to obtain a reaction mixture.

[0051] Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com