Preparation process of composite coating layer based on cutting tool

A cutting tool and composite coating technology, which is applied in the field of composite coating preparation technology, can solve the problems of poor coating conductivity, low tool toughness and long service life, and achieve good conductivity, long service life and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

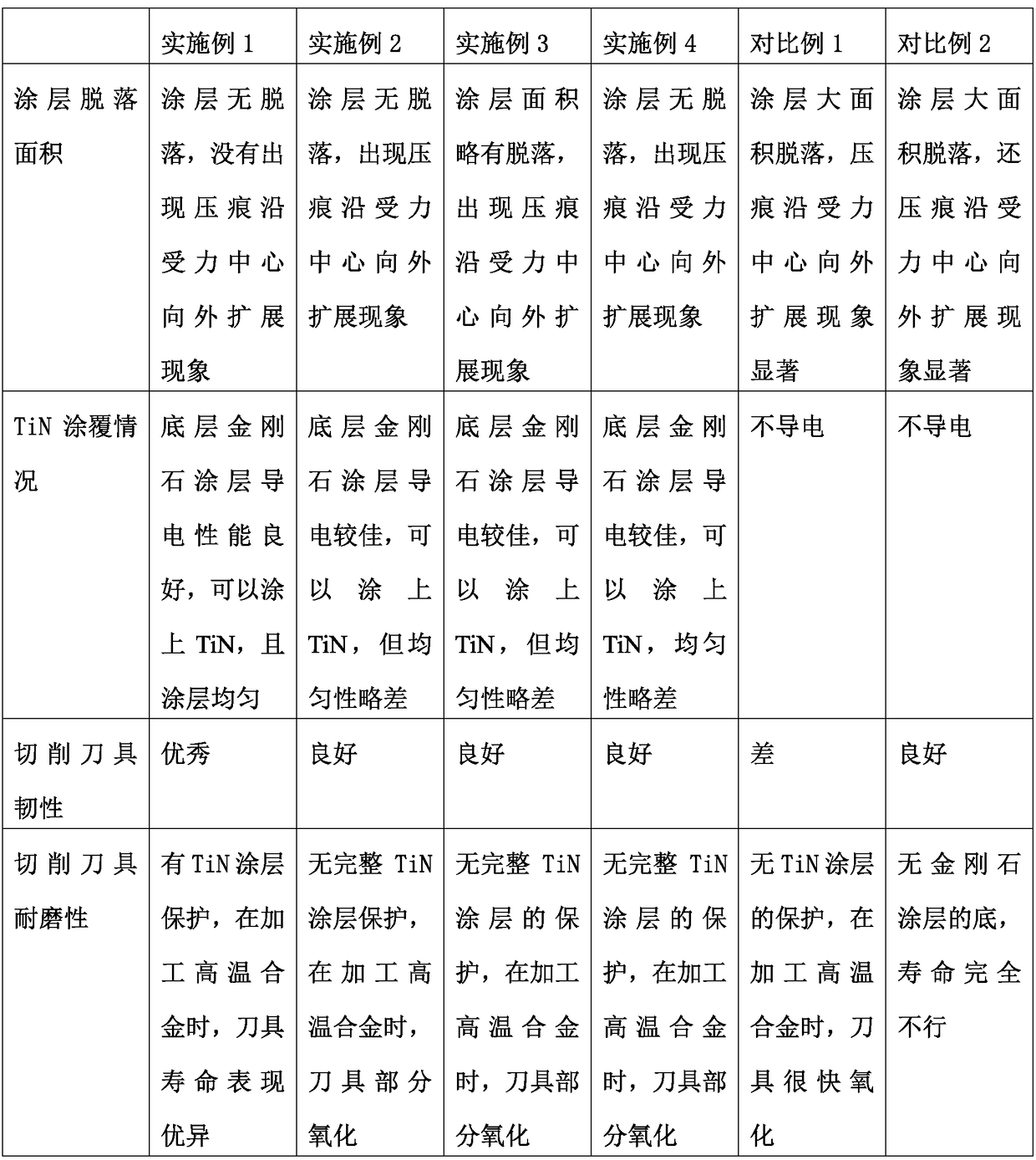

Examples

Embodiment 1

[0022] A composite coating preparation process based on a cutting tool, including a CVD coating process inside the cutting tool and a PVD coating process outside the CVD coating; wherein,

[0023] The CVD coating process on the inside of cutting tools consists of the following steps:

[0024] Step 1: The cutting tool is subjected to cleaning pretreatment and cobalt removal pretreatment in sequence, and the cutting tool after decobalt pretreatment is cleaned and dried for use; it should be noted that the pre-cleaning treatment refers to the organic Dirt removal. Can be treated with alcohol or acetone. Decobalt pretreatment is to remove cobalt on the surface of cutting tools to improve the adhesion of later composite coatings. Cobalt removal pretreatment includes alkali etching with inorganic alkali solution for 2-20 minutes, cleaning after alkali etching, and then putting in inorganic acid solution for acid etching for 2-15 minutes. In this embodiment, the inorganic alkali s...

Embodiment 2

[0028] A composite coating preparation process based on a cutting tool, including a CVD coating process inside the cutting tool and a PVD coating process outside the CVD coating; wherein,

[0029] The CVD coating process on the inside of cutting tools consists of the following steps:

[0030] Step 1: Clean the cutting tool with alcohol before cleaning, and then use an inorganic alkali solution as w(KOH):w(K 3 [Fe(CN) 6 ]): w(H 2 O)=1:1:10, the alkali etching time is 10min, and the inorganic acid solution is v(H 2 SO 4 ):v(H 2 (0)=1:10, the acid etching time is 10min to carry out decobalt pretreatment, and the cutting tool after decobalt pretreatment is cleaned and dried for use.

[0031] Step 2: Put the cutting tool to be used in step 1 into the CVD diamond deposition furnace, then evacuate the CVD diamond deposition furnace, the pressure in the furnace should not be higher than 10pa, and then follow the CH4 、H 2 , N 2 The gas flow rate ratio is 1:250:1 into CH 4 、H 2...

Embodiment 3

[0034] A composite coating preparation process based on a cutting tool, including a CVD coating process inside the cutting tool and a PVD coating process outside the CVD coating; wherein,

[0035] The CVD coating process on the inside of cutting tools consists of the following steps:

[0036] Step 1: The cutting tool is cleaned with acetone before treatment, and then the inorganic alkali solution is used as w(KOH):w(K 3 [Fe(CN) 6 ]): w(H 2 O)=1:1:10, the alkaline etching time is 15min, and the inorganic acid solution is v(H 2 SO 4 ):v(H 2 (0)=1:10, the acid etching time is 13min for decobalt pretreatment, and the cutting tool after decobalt pretreatment is cleaned and dried for use.

[0037] Step 2: Put the cutting tool to be used in step 1 into the CVD diamond deposition furnace, then evacuate the CVD diamond deposition furnace, the pressure in the furnace should not be higher than 10pa, and then follow the CH 4 、H 2 , N 2 The gas flow rate ratio is 1:100:3 into CH 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com