A kind of cerium-doped nano-titanium dioxide photocatalyst and its pyrolysis preparation method

A nano-titanium dioxide and photocatalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve obvious agglomeration phenomenon, high equipment requirements, complex methods, etc. problems, to achieve the effect of high purity, low equipment requirements, and simple and efficient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 42.64ml of glacial acetic acid and 21.28ml of butyl titanate into the reaction vessel, and stir with a glass rod while adding. Then, 0.27 g of cerium nitrate and 50 ml of ethanol were sequentially added to obtain a mixed solution.

[0037] (2) Put the obtained mixed solution into an ultrasonic oscillator, and ultrasonically vibrate twice, 20 minutes each time. Then, after heating and evaporating to dryness at a temperature of 110° C., the nano-titanium dioxide precursor powder doped with cerium is obtained.

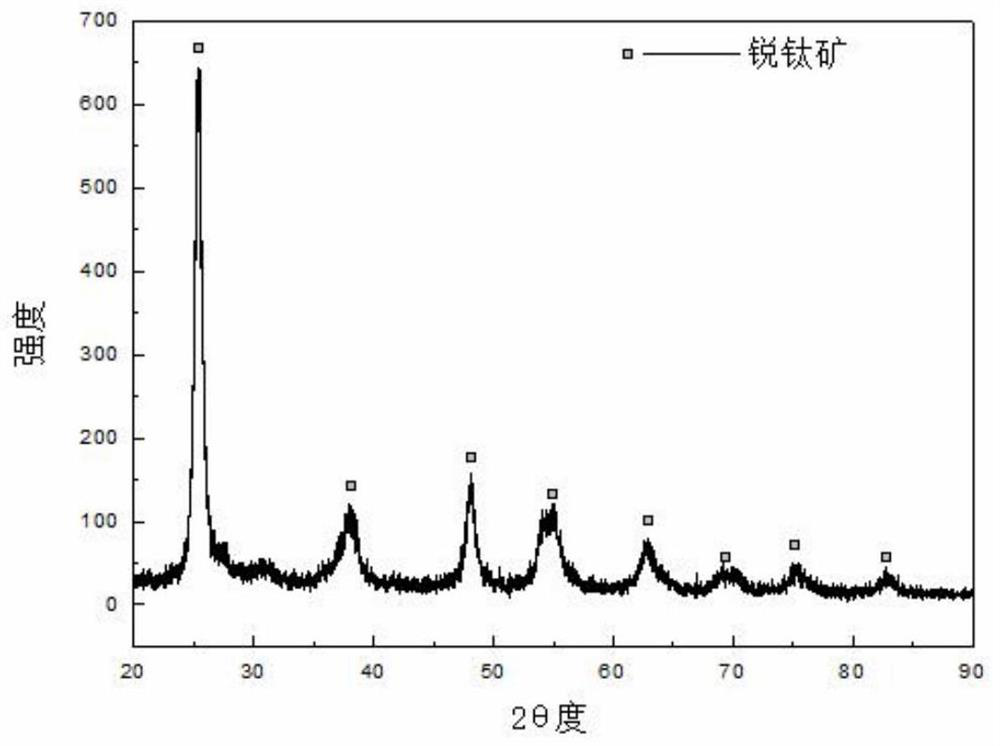

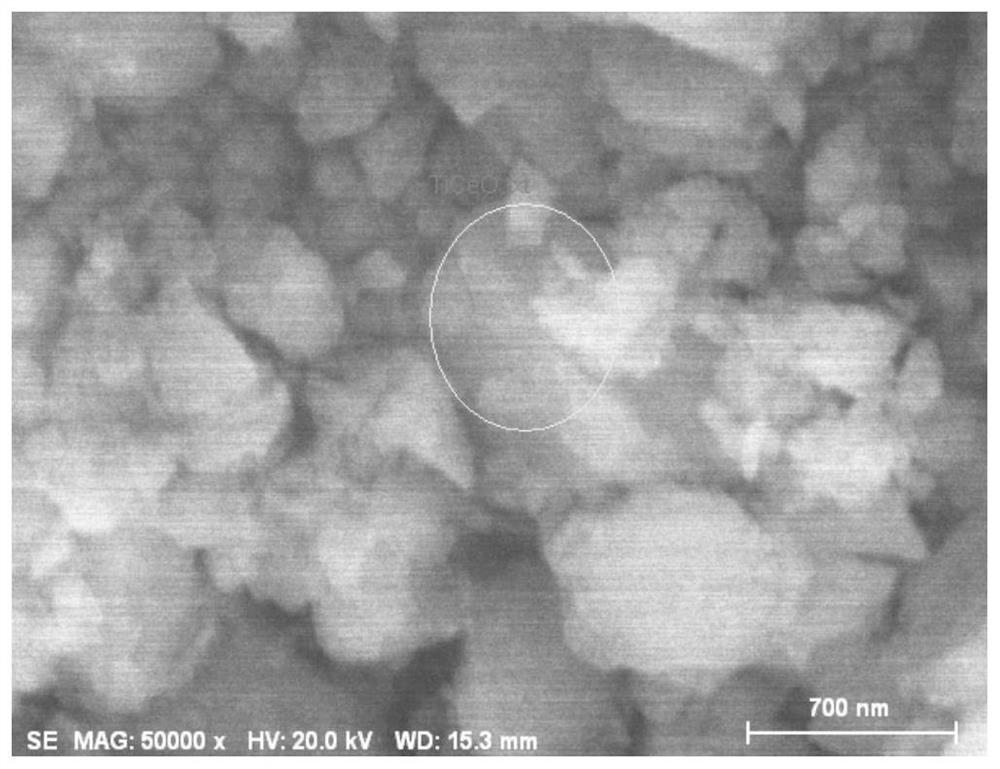

[0038] (3) Put the obtained nano-titanium dioxide precursor powder doped with cerium into a muffle furnace, set the temperature at 120°C, dry it for 2 hours, place it in the muffle furnace, heat it up to 600°C, and keep it for 1.5 hours , keep the furnace closed, and cool down to room temperature to obtain nano-titanium dioxide doped with cerium. figure 1 It is an electron diffraction XRD pattern of the cerium-doped titanium dioxide powder obtained in thi...

Embodiment 2

[0040] (1) Add 40.764ml of glacial acetic acid and 20.382ml of butyl titanate into the reaction vessel, and stir with a glass rod while adding. Then, 0.7921 g of cerium nitrate and 55 ml of ethanol were sequentially added to obtain a mixed solution.

[0041] (2) Put the obtained mixed solution into an ultrasonic oscillator, and ultrasonically oscillate 3 times, 30 minutes each time. Then, it was heated and evaporated to dryness at 120° C. to obtain nano-titanium dioxide precursor powder doped with cerium.

[0042] (3) Put the obtained cerium-doped nano-titanium dioxide precursor powder into the muffle furnace, set the temperature at 120°C, dry it for 2 hours, place it in the muffle furnace, heat it up to 600°C, and keep it warm for 1 hour , keep the furnace closed, and cool down to room temperature to obtain nano-titanium dioxide doped with cerium. The obtained crystal form belongs to anatase type, and the degree of crystallization is good. Put it into sewage for photocatal...

Embodiment 3

[0044] (1) Add 39.06ml of glacial acetic acid and 19.53ml of butyl titanate into the reaction vessel, and stir with a glass rod while adding. Then, 1.29 g of cerium nitrate and 50 ml of ethanol were sequentially added to obtain a mixed solution.

[0045] (2) Put the obtained mixed solution into an ultrasonic oscillator, and ultrasonically oscillate 3 times, 30 minutes each time. Then, after heating and evaporating to dryness at 120° C., a cerium-doped nano-titanium dioxide precursor powder is obtained.

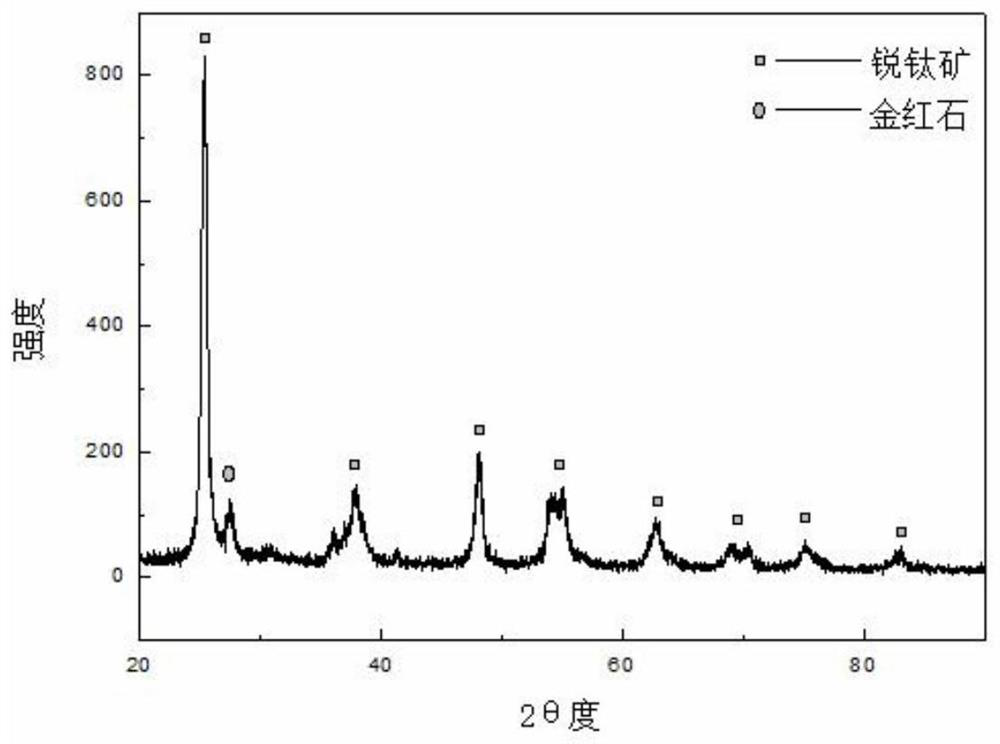

[0046] (3) The obtained cerium-doped nano-titanium dioxide precursor powder is put into a muffle furnace, the temperature is set at 120° C., dried for 2 hours, placed in the muffle furnace, the temperature is programmed to 600° C., and after 2 hours of heat preservation, Keep the furnace closed and cool down to room temperature to obtain nano-titanium dioxide doped with cerium. The obtained crystal form belongs to anatase type, and the degree of crystallization is good. Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com