Preparation method of dimethyl silicone oil with high conversion rate and low ring content

A technology of simethicone oil and high conversion rate, which is applied in the field of synthesis of simethicone oil with high conversion rate and low ring body content, and can solve the problems of low primary conversion rate, difficulty in removing a small amount of residual ring body, and wide molecular weight distribution. , to achieve the effects of simplifying the production process, promoting redistribution, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

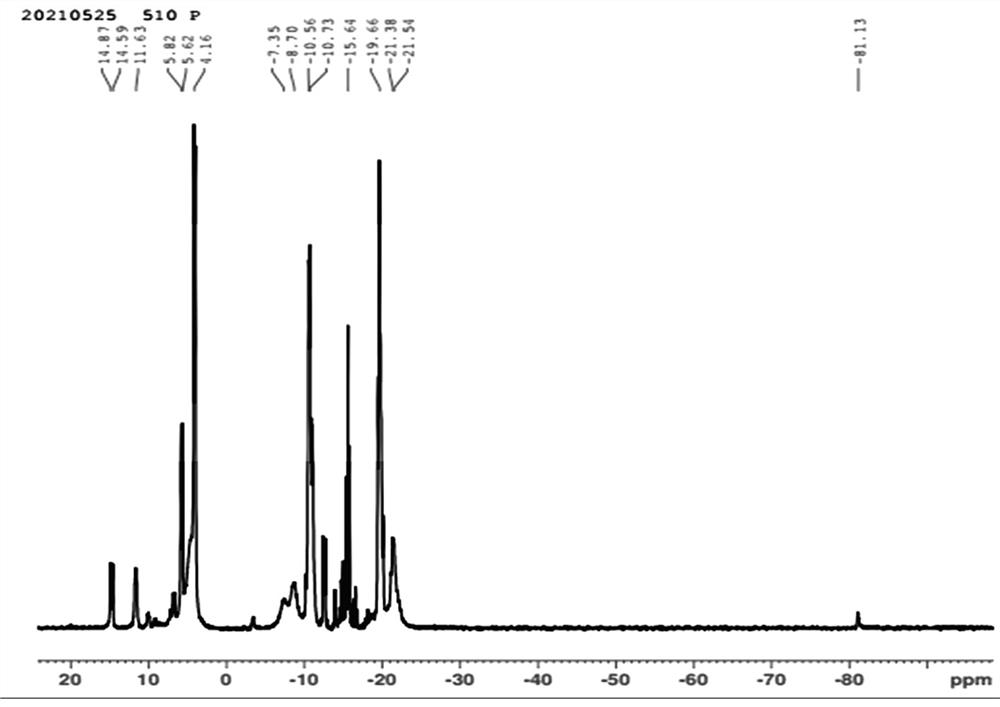

[0029] The preparation method of linear phosphazene chloride catalyst

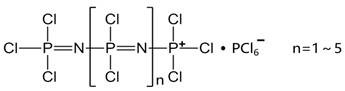

[0030] Add 20.5g of phosphorus pentachloride, 2.6g of ammonium chloride, and 100mL of tetrachloroethane into a 250ml three-necked flask, reflux at 150°C for 6 hours, cool to room temperature after the reaction, inject the reaction solution into 100ml of petroleum ether, and precipitate Precipitation. After the precipitation was washed with petroleum ether for many times, the residual petroleum ether was removed under reduced pressure to obtain a linear phosphazene chloride catalyst. The structural formula is as follows, and the nuclear magnetic spectrum is shown in the attached figure 1 .

[0031]

[0032] Linear phosphazene chloride structure.

Embodiment 2

[0034] Add 300g of highly linear siloxane hydrolyzate into a three-necked flask, stir and heat up to 70°C, add 40g of simethicone oil with a viscosity of 10cSt, stir well and add 0.7g of dimethicone with a content of 2wt% linear phosphazene chloride Methyl silicone oil solution. (2wt% means that the amount of linear phosphazene chloride in the catalyst solution is 2wt%, and the examples 3-12 all have the same meaning, only the addition amount is different) Under the negative pressure condition of 0.08Mpa lower than the atmospheric pressure, react for 3h, After the reaction, restore the system pressure to normal pressure, add 0.1 g of hexamethyldisilazane and stir for 0.5 h to neutralize the catalyst, raise the temperature to 200° C., cool down to obtain the finished product. The conversion rate is 98.21%, the viscosity is 14040cp, and the volatile matter is 0.21%.

Embodiment 3

[0036] Add 300g of highly linear siloxane hydrolyzate into a three-necked flask, stir and heat up to 70°C, add 41g of simethicone oil with a viscosity of 2cSt, stir well and add 0.84g of dimethicone with a content of 2wt% linear phosphazene chloride Methyl silicone oil solution, adjust the system pressure to 0.02Mpa lower than the atmospheric pressure and react for 2 hours. After the reaction, restore the system pressure to normal pressure, add 0.134g of hexamethyldisilazane and stir for 0.5h to neutralize the catalyst. Raise the temperature to 200°C to lower the temperature, cool and filter to obtain the finished product. The appearance of the finished product is transparent, the conversion rate is 98.46%, the viscosity is 88cSt, and the volatile matter is 0.14%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com