A kind of preparation method of superfine tungsten powder composite powder

A technology of composite powder and ultra-fine tungsten powder, which is applied in the field of preparation of ultra-fine tungsten powder composite powder, can solve the problems of unsuitability for large-scale industrial production, uneven powder properties, and difficulty in continuous production, etc. The effect of environmental protection process, stable reaction and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

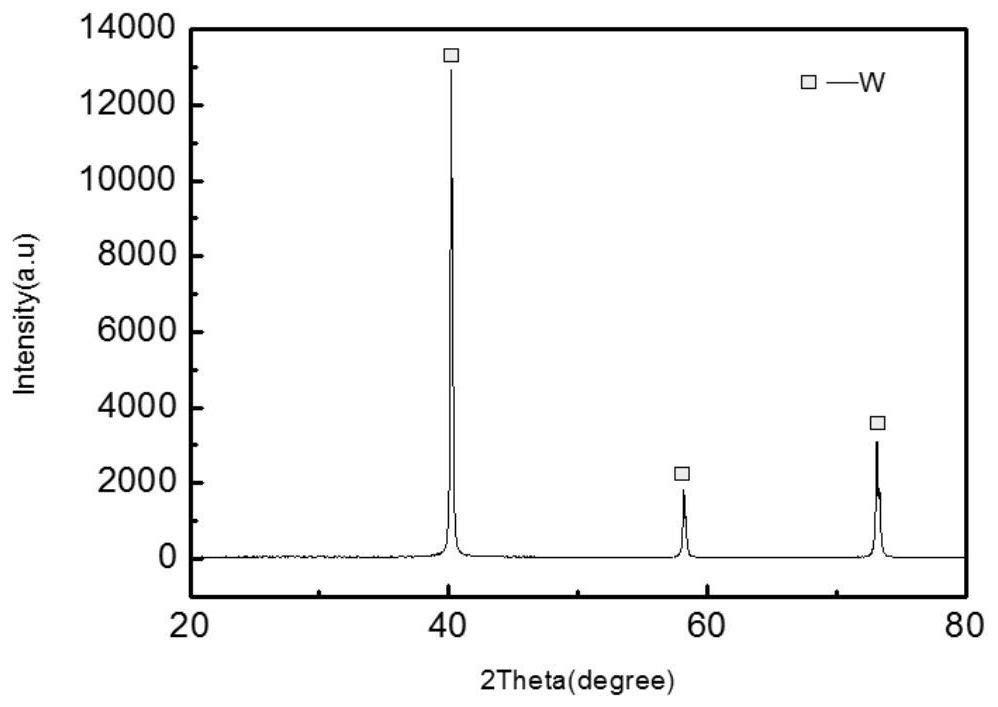

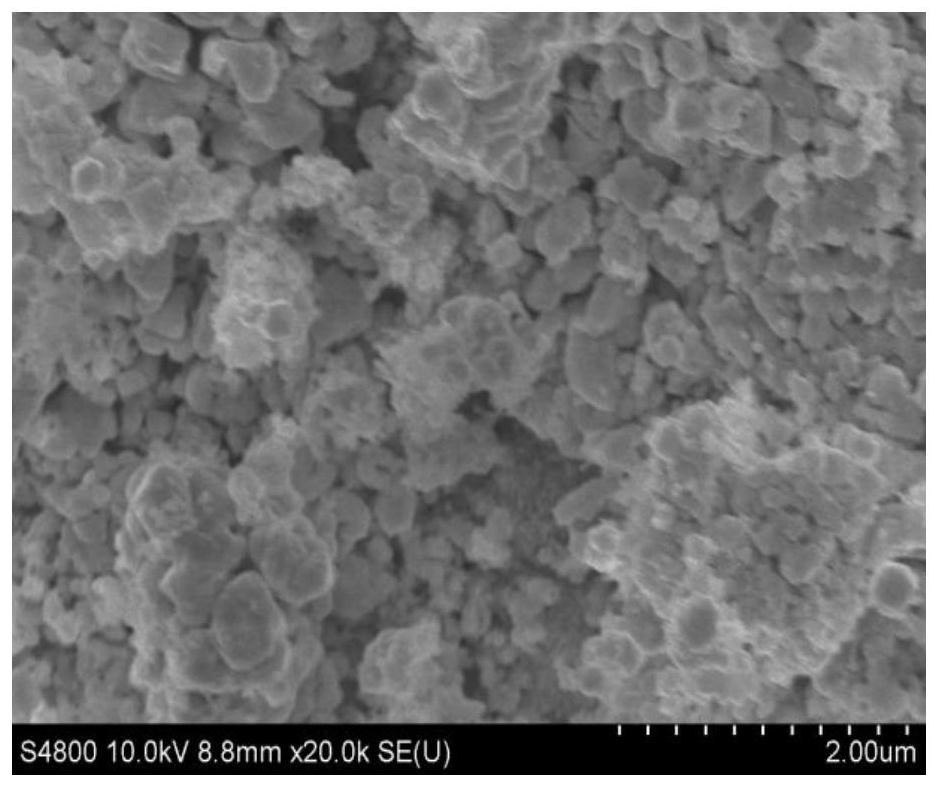

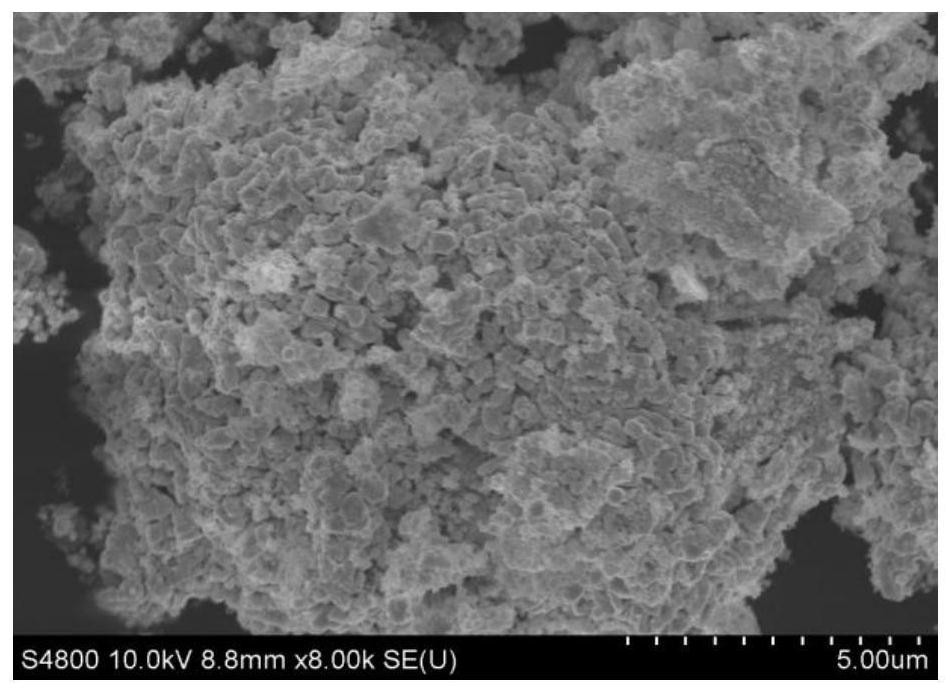

Image

Examples

Embodiment 1

[0027] 1) Heat deionized water or distilled water to 62°C; then add ammonium metatungstate, ammonium molybdate, lanthanum nitrate and ammonium metavanadate in sequence, the addition amount is 14g / L, 0.5g / L, 0.02g respectively / L and 0g / L, stir to dissolve completely and continue to stir for 0.5h; continue to heat until boiling and evaporation to obtain tungsten trioxide precursor powder;

[0028] 2) Put the ultra-fine tungsten trioxide composite powder in a tube furnace, pass in hydrogen gas, and reduce to obtain tungsten powder; place the tungsten powder in a high-temperature reaction furnace, and fully oxidize the tungsten trioxide composite powder; put tungsten trioxide Powder --- tungsten powder --- tungsten trioxide powder The process is repeated 5 times to obtain small particles of tungsten trioxide composite powder;

[0029] 3) Put small particles of tungsten trioxide composite powder in a planetary ball mill, ball mill for 4 hours, and the rotation speed is 200r / min, t...

Embodiment 2

[0033] 1) Heat deionized water or distilled water to 65°C; then add ammonium metatungstate, ammonium molybdate, ammonium nitrate and ammonium metavanadate in sequence, the addition amount is 17g / L, 0.8g / L, 0.05g respectively / L and 0.2g / L, stir to dissolve completely and continue to stir for 1h; continue to heat until boiling and evaporation to obtain tungsten trioxide precursor powder;

[0034] 2) Put the tungsten trioxide composite powder in a tubular furnace, pass in hydrogen gas, and reduce to obtain tungsten powder; place the tungsten powder in a high-temperature reaction furnace, and fully oxidize the tungsten trioxide composite powder; put the tungsten trioxide powder ------Tungsten powder------Tungsten trioxide powder The process is repeated 3 times to obtain small particles of tungsten trioxide composite powder;

[0035] 3) Put small particles of tungsten trioxide composite powder in a planetary ball mill, ball mill for 3 hours, and the rotation speed is 300r / min to o...

Embodiment 3

[0039] 1) Heat deionized water or distilled water to 70°C; then add ammonium metatungstate, ammonium molybdate, lanthanum nitrate and ammonium metavanadate in sequence, the addition amount is 15g / L, 0.6g / L, 0.05g respectively / L and 0.1g / L, stir to dissolve completely and continue to stir for 0.7h; continue to heat until boiling and evaporation to obtain tungsten trioxide precursor powder;

[0040] 2) Put the tungsten trioxide composite powder in a tubular furnace, pass in hydrogen gas, and reduce to obtain tungsten powder; place the tungsten powder in a high-temperature reaction furnace, and fully oxidize the tungsten trioxide composite powder; put the tungsten trioxide powder ------Tungsten powder------Tungsten trioxide powder The process is repeated 4 times to obtain small particles of tungsten trioxide composite powder;

[0041]3) Put the small-particle tungsten trioxide composite powder in a planetary ball mill, mill for 4 hours, and the rotation speed is 250r / min to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com