High-strength heat-resistant cast aluminum-copper alloy with low porosity and preparation process

A preparation process and a technology for casting aluminum, applied in the field of high-strength and heat-resistant casting aluminum-copper alloy and preparation process, can solve the problems of inapplicability and large loss of aluminum liquid, and achieve the effects of low porosity, low equipment requirements, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

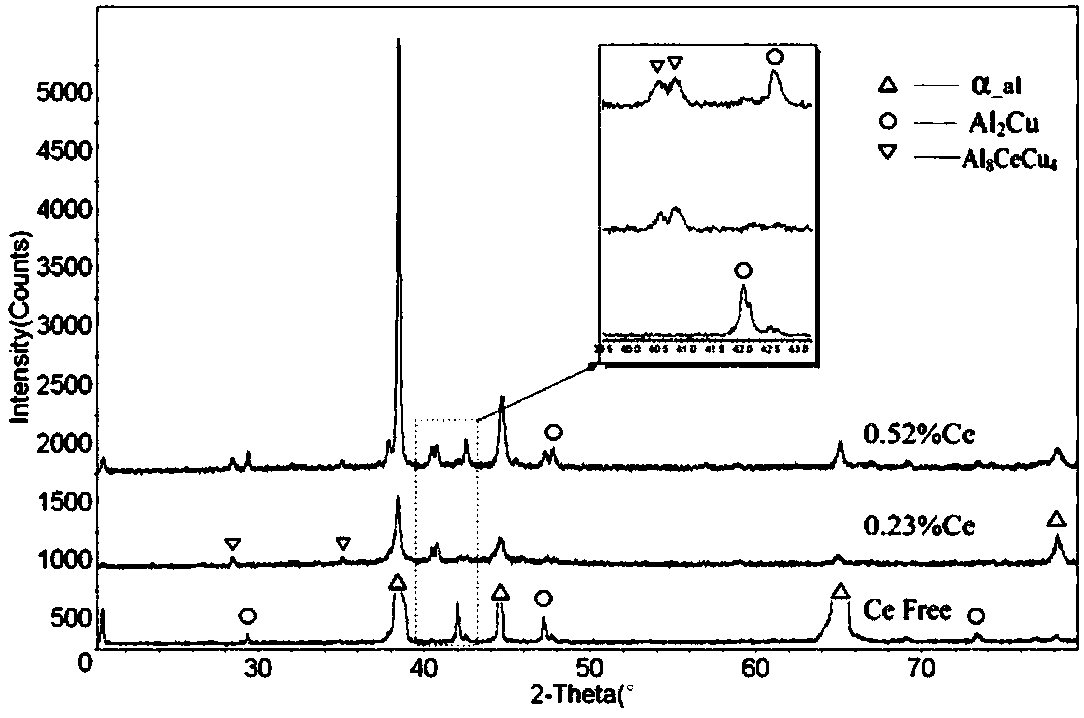

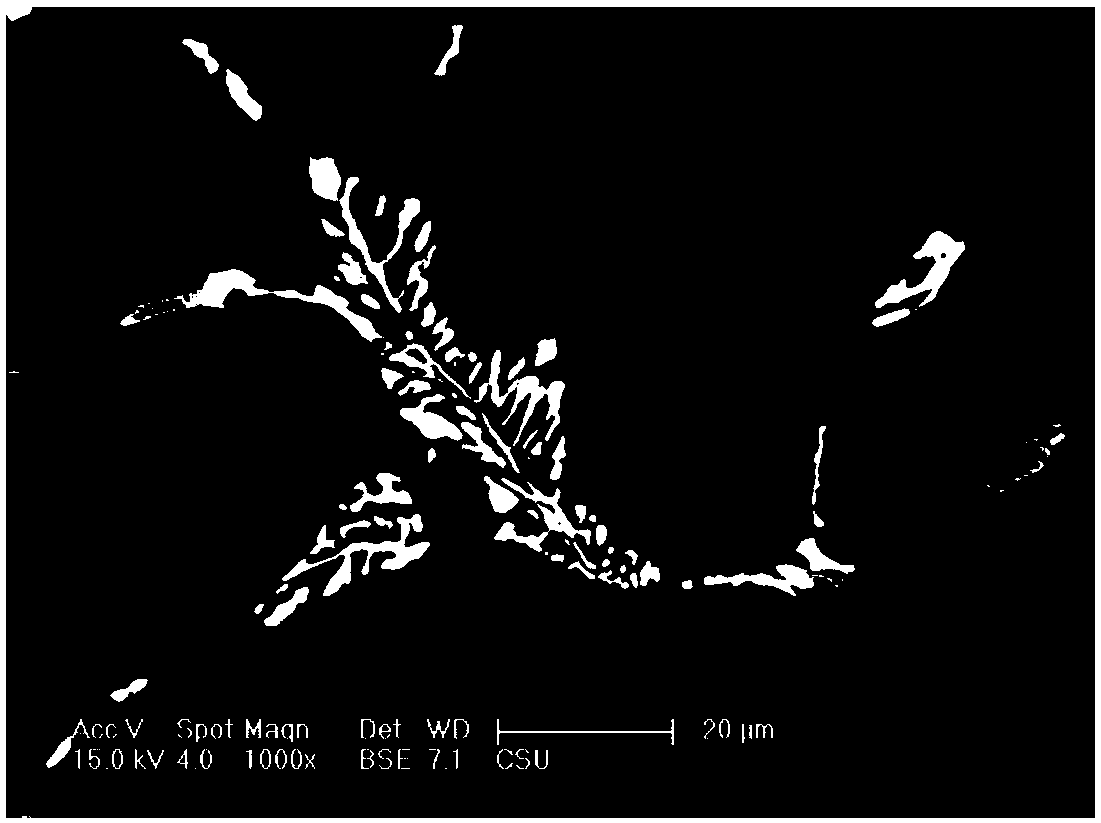

[0046] The alloy composition is: 0.14% V, 0.08% Zr, Zr / V=0.571, RE0.036 (rare earth Ce), 0.38% Ti, 0.08% B, 6.52% Cu, 0.23% Ag, 0.08% Mg, 0.34% Mn, The balance is Al, and the sum of each component is 100%.

[0047] The smelting and casting process of the alloy follows the following steps: (1) According to the above formula, configure 300kg of the cast aluminum alloy material, wherein Al, Ag, and Mg are pure metals, and the remaining elements are aluminum intermediate alloys, and the surface of the above metals is cleaned. No dust, oil, pure Mg is wrapped tightly with aluminum foil, and then baked at 150-300°C for 1-2 hours; (2) The surface of the tools used for alloy melting and casting needs to be cleaned and pre-painted with zinc oxide paint, and then baked at 150-300°C for 1-2 hours; Dry and preheat at 300°C for 3 to 5 hours, and at the same time, dry and preheat the sand mold in a drying furnace at 200 to 400°C for 2 to 4 hours; (3) first melt pure Al in a melting furnace ...

Embodiment 2

[0050] The alloy composition is: 0.23% V, 0.05% Zr, Zr / V=0.217, RE0.014 (rare earth Y), 0.29% Ti, 0.06% B, 4.84% Cu, 0.52% Ag, 0.32% Mg, 0.27% Mn, The balance is Al, and the sum of each component is 100%.

[0051] The melting and casting process of the alloy is the same as in Example 1.

[0052] The casting body is firstly subjected to 515°C / 12h solution heat treatment, and then 175°C / 4h artificial aging heat treatment. Its room temperature and high temperature tensile properties are shown in Table 1.

Embodiment 3

[0054] The alloy composition is: 0.28% V, 0.04% Zr, Zr / V=0.143, RE0.01 (rare earth Yb), 0.20% Ti, 0.04% B, 7.70% Cu, 0.85% Ag, 0.38% Mg, 0.31% Mn, The balance is Al, and the sum of each component is 100%.

[0055] The melting and casting process of the alloy is the same as in Example 1.

[0056] The casting body is firstly subjected to 530°C / 2h solution heat treatment, and then 185°C / 2h artificial aging heat treatment. Its room temperature and high temperature tensile properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com