Single-crystal-silicon surface mechanical damage detecting method based on conductivity variation

A technology of mechanical damage and detection methods, which is applied in the direction of measuring devices, instruments, scanning probe microscopy, etc., can solve the problems of difficult to adjust the detection position in time, the detection process and results are out of sync, and the sample preparation process is complicated, etc. The results are online controllable, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

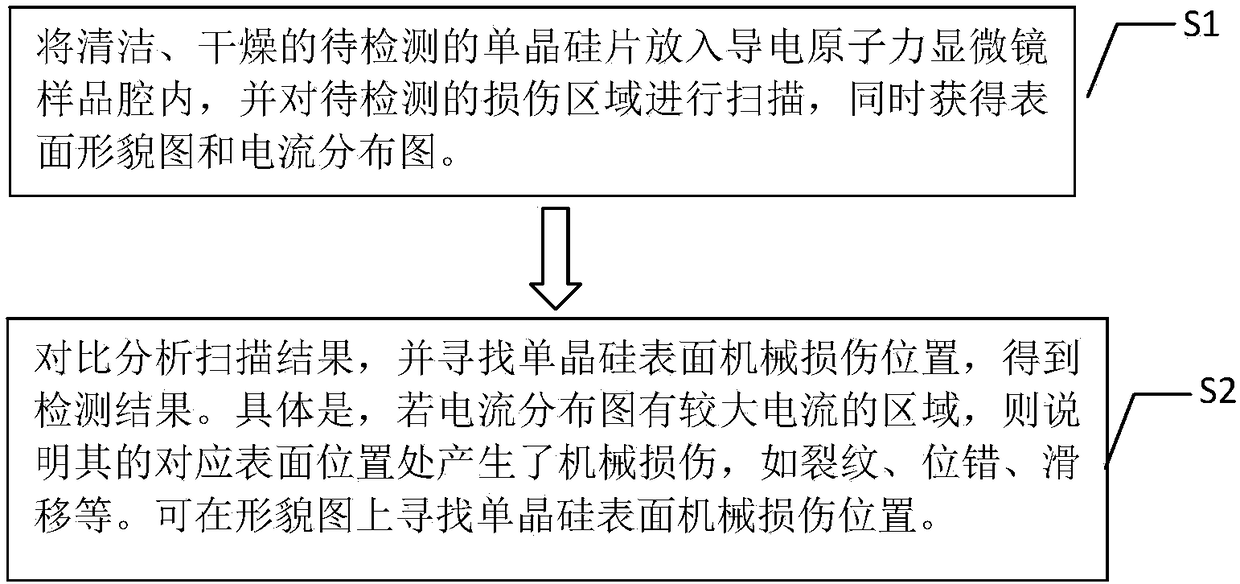

[0027] Such as figure 1 As shown, a method for detecting mechanical damage on the surface of single crystal silicon based on conductivity change, comprising the following steps:

[0028] S1. Put the clean and dry single crystal silicon wafer to be tested into the sample cavity of the conductive atomic force microscope, scan the surface damage area to be tested, and obtain the surface topography and current distribution map at the same time.

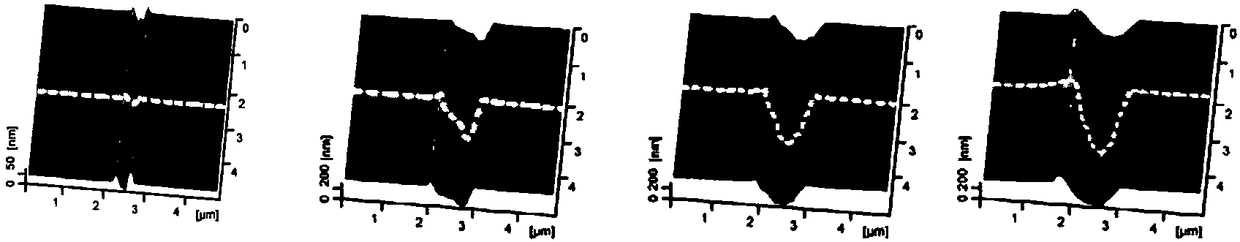

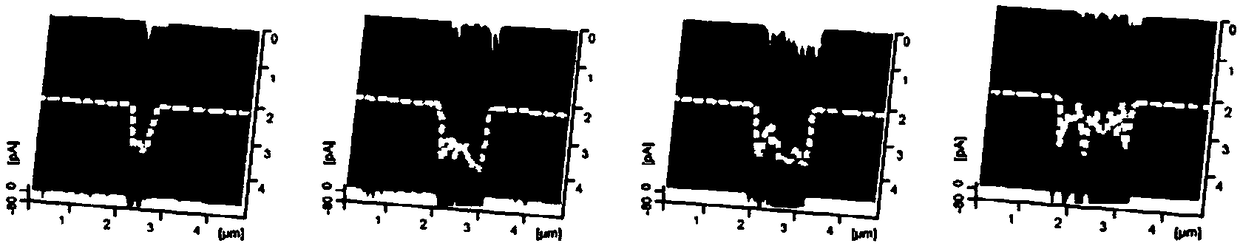

[0029] The surface of single crystal silicon is scratched with a diamond tip to obtain mechanical scratches. In this embodiment, the radius of curvature of the diamond tip is 10 μm, the load is 5 mN-20 mN, and the number of cycles is 1. After the scribing is completed, put the monocrystalline silicon wafer in absolute ethanol and acetone and clean it ultrasonically for three minutes, rinse and dry it with deionized water, and put the cleaned and dried monocrystalline silicon wafer into the conductive atomic force microscope. Inside the ...

Embodiment 2

[0035] Such as figure 1 As shown, a method for detecting mechanical damage on the surface of single crystal silicon based on conductivity change, comprising the following steps:

[0036] S1. Put the clean and dry single crystal silicon wafer to be tested into the sample cavity of the conductive atomic force microscope, scan the surface damage area to be tested, and obtain the surface topography and current distribution map at the same time.

[0037] The single crystal silicon wafer with a non-destructive groove structure on the surface to be tested is placed in absolute ethanol and acetone, ultrasonically cleaned for three minutes, rinsed with deionized water and dried. Put the single crystal silicon wafer after the cleaning and drying steps into the sample cavity of the conductive atomic force microscope, and scan the damaged area to be detected.

[0038] In order to prevent the anodic oxidation reaction and displacement current on the surface of the single crystal silicon w...

Embodiment 3

[0042] Such as figure 1 As shown, a method for detecting mechanical damage on the surface of single crystal silicon based on conductivity change, comprising the following steps:

[0043] S1. Put the clean and dry single crystal silicon wafer to be tested into the sample cavity of the conductive atomic force microscope, scan the surface damage area to be tested, and obtain the surface topography and current distribution map at the same time.

[0044]The single crystal silicon wafer was polished on a polishing machine for 10 minutes, the polishing particles used in the polishing machine were silicon carbide, and the rotational speed of the polishing machine was set at 100 r / min. The polished silicon wafers were removed and placed in absolute ethanol and acetone in sequence, ultrasonically cleaned for three minutes, rinsed with deionized water and dried. Put the single crystal silicon wafer after the cleaning and drying steps into the sample cavity of the conductive atomic force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com