A kind of ozone decomposition catalyst and its preparation method and application

An ozone decomposition and catalyst technology, applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Ozone decomposition active site, efficient ozone decomposition ability, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 3.16 g of potassium permanganate is soluble in 50 ml of deionized water, and the alumina ball of 150 g of a particle size of 2 to 3 mm is mixed with the resulting solution, and the potassium permanganate solution will completely wet the alumina ball after 120 ° C. Drying; 25 ml of ethanol and 5 ml of glacial acetic acid are dissolved in 30 ml of deionized water, then mixed with dry carrier, so that the liquid is sufficiently infiltrating the carrier and stirring, then placed in an oven at 50 ° C for 1 h, remove extra After the moisture obtained, the manganese precursor was coated; placed in a muffle furnace, raised at a rate of 5 ° C / min to 500 ° C calcined for 3 h, and the catalyst product was obtained after natural cooling.

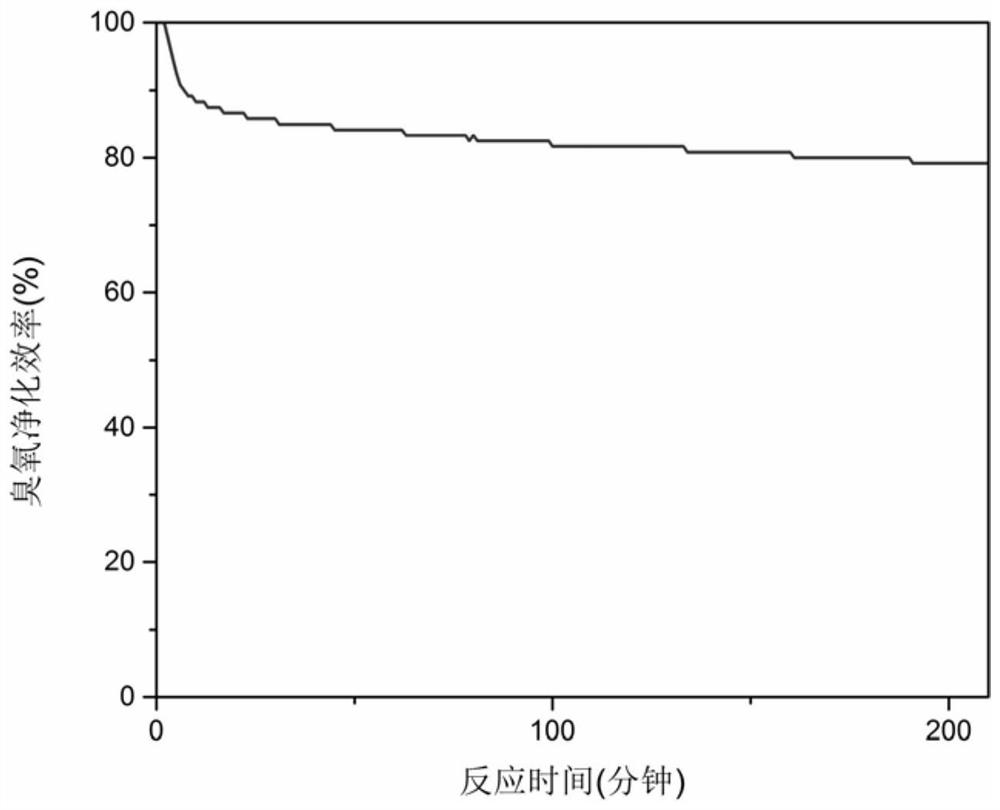

[0050] In this embodiment, the mammanese oxide catalyst was prepared by using ethanol using ethanol on the surface of the alumina spheroid. The outer surface of the catalyst was evenly brownish black, and the molded catalyst was not removed. Evalua...

Embodiment 2

[0052] 3.16 g of potassium permanganate is soluble in 50 ml of deionized water, and the activated carbon particles 150g having a diameter of 2 to 3 mm are mixed with the resulting solution, and the potassium permanganate solution is completely wetted at 120 ° C after drying; 25 ml of ethanol and 5 ml of glacial acetic acid were dissolved in 30 ml of deionized water, then mixed with dry carrier, so that the liquid sufficiently infiltrated the carrier and stirred, mixed the solution and activated carbon particles, so that the liquid sufficiently infiltrated the carrier and stirred, then put it in an oven The constant temperature reactive reaction at 60 ° C, the regular carrier obtained by the manganese precursor obtained after the excess moisture was removed; the resulting carrier was placed in a muffle furnace, and the rate was raised to 550 ° C for 2.5 h at a rate of 5 ° C / min. Naturally, the catalyst product is obtained.

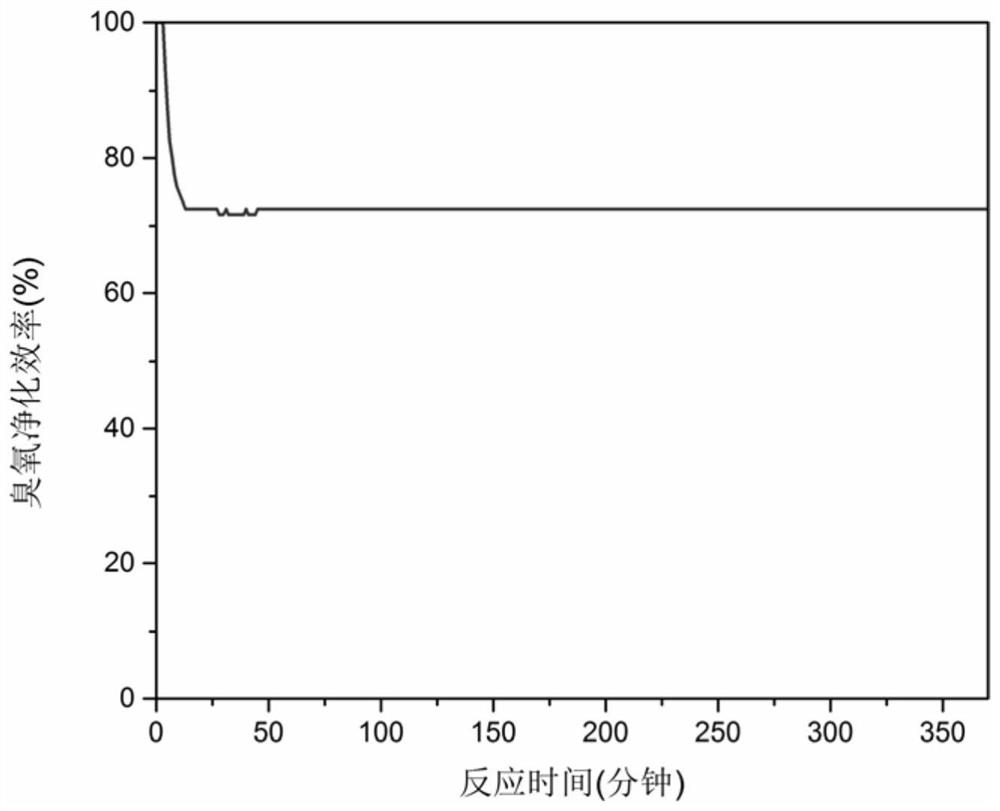

[0053] In this embodiment, the cementation of potassium...

Embodiment 3

[0055] 6.76 g of manganese sulfate is dissolved in 50 ml of deionized water, and the alumina ball of 150 g of a particle size of 2 to 3 mm is mixed with the resulting solution, the manganese sulfate is completely wetted after drying at 120 ° C after mixing the alumina ball; 9.12 g of ammonium sulfate, 5.28 g of ammonium sulfate and 10 g of potassium nitrate were dissolved in 50 ml deionized water, and then mixed with dry carrier, so that the liquid sufficiently infiltrated the carrier and stirred, then placed in an oven at 50 ° C at 50 ° C at 50 ° C. 1H, the regular carrier obtained by the manganese precursor obtained after excess moisture was removed; the resulting carrier was placed in a muffle furnace, raised at a rate of 5 ° C / min, and calcined for 3 h at a rate of 500 ° C, naturally catalyst product.

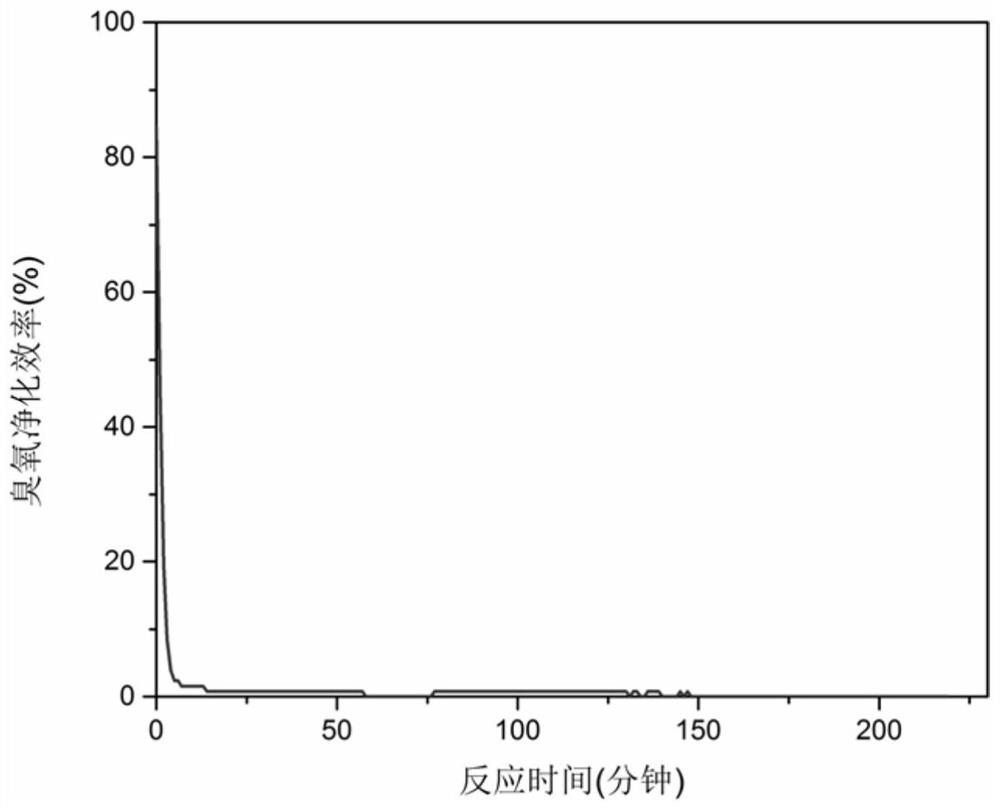

[0056] In this example, manganese dioxide catalysts were formed by oxidizing manganese sulfate using sulfate, and the outer surface of the catalyst was uniform, and the formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com