Method for separating and recycling precious metal in copper anode mud high acid leaching liquor

A technology of high-acid leaching and copper anode slime, applied in the direction of improving process efficiency, etc., to achieve the effects of promoting diffusion, reducing the loss of palladium, common raw materials and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

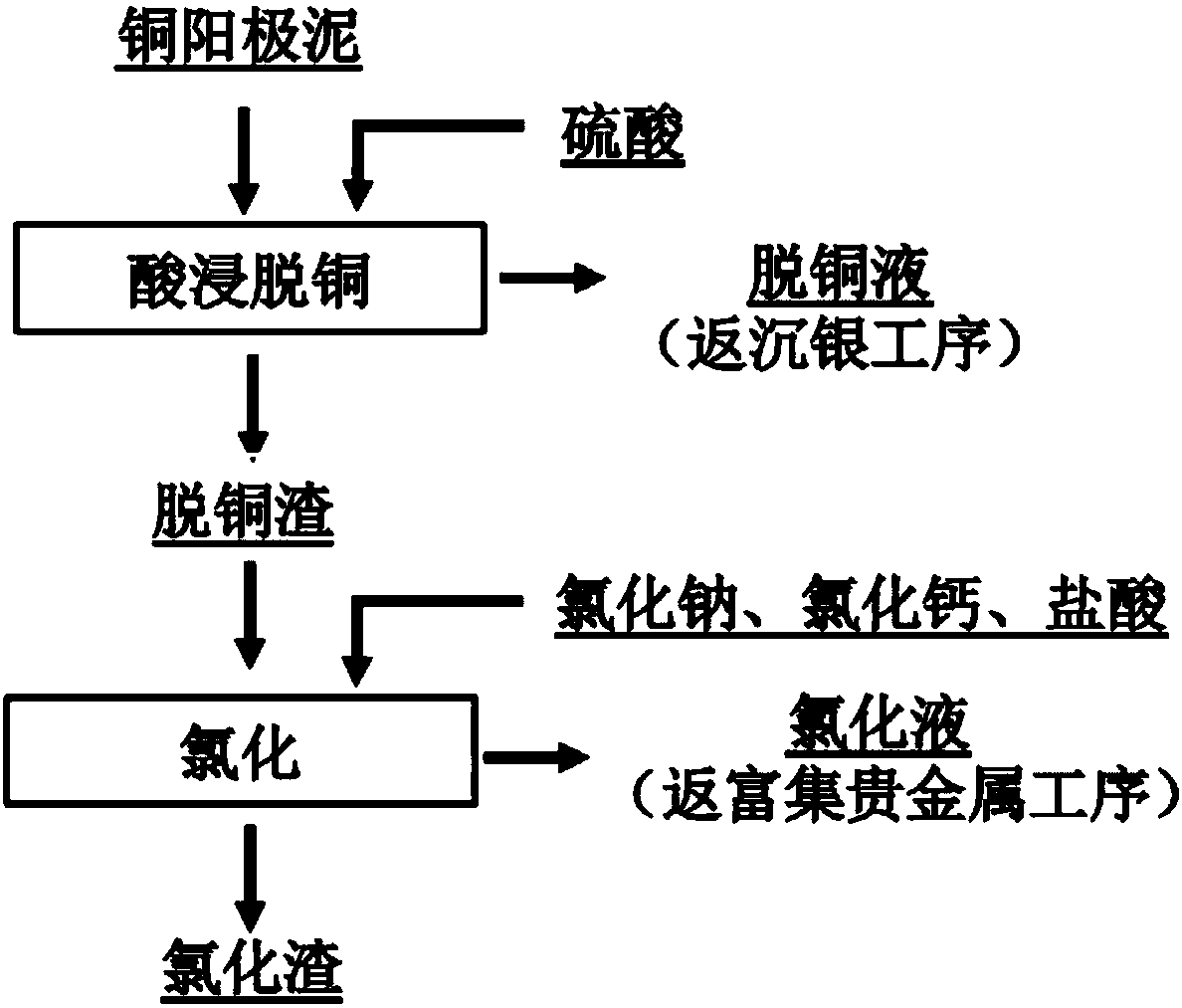

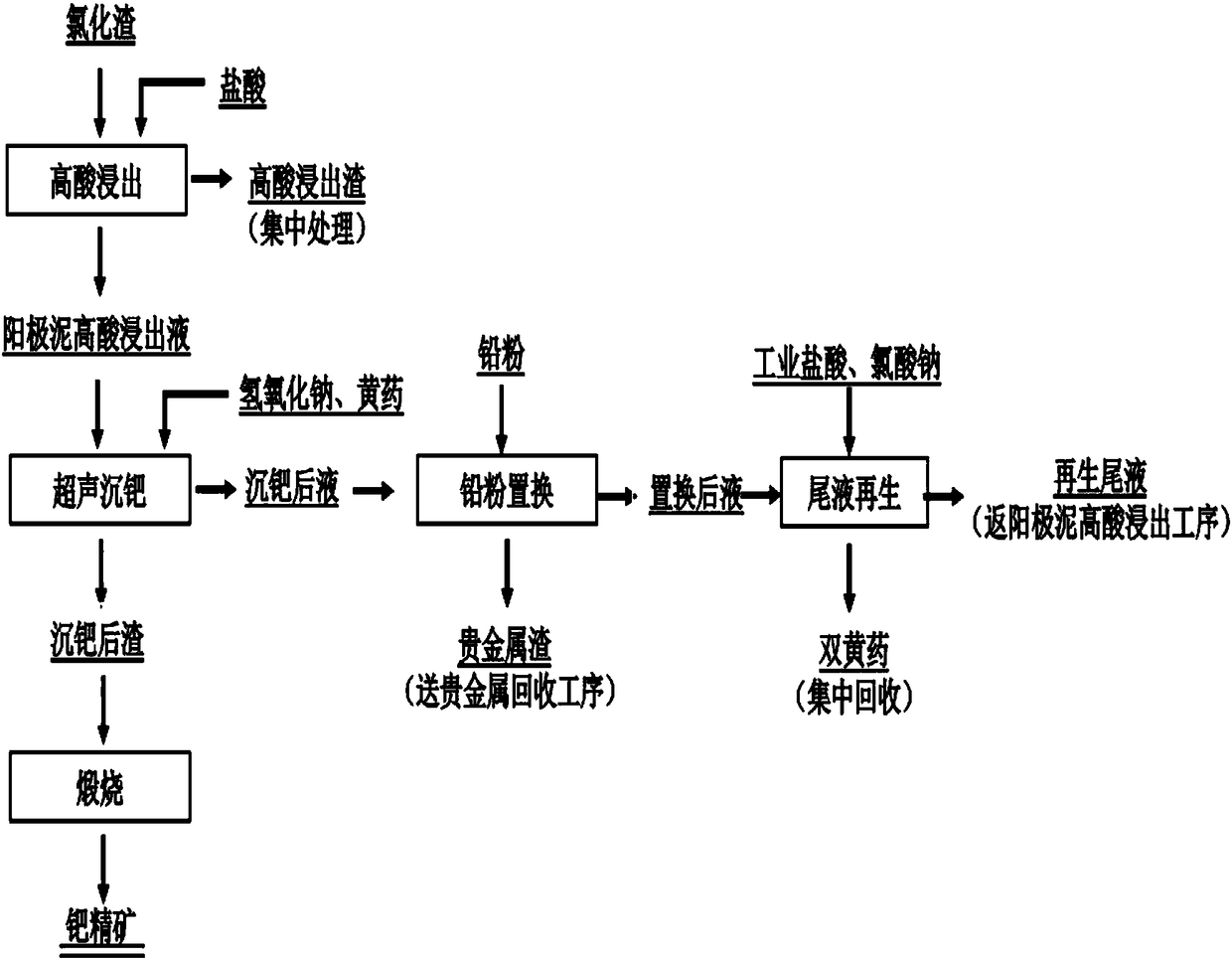

Method used

Image

Examples

Embodiment 1

[0021] Follow the steps below to recycle:

[0022] (1) High-acid leaching: high-acid leaching of the anode slime chlorinated slag, the leaching solution is a hydrochloric acid solution with an acidity of 4mol / L, the mass ratio of the leaching solution to the chlorinated slag is 3:1, the leaching temperature is 35°C, and the leaching time is For 0.5 hour, high-acid leaching solution and high-acid leaching slag were obtained, and the high-acid leaching slag was concentrated treatment;

[0023] (2) Ultrasonic precipitation of palladium: the anode slime high-acid leaching solution obtained in step (1) is placed in an ultrasonic device, the pH of the acid leaching solution is adjusted to 0.2 with sodium hydroxide, ethyl xanthate is added, and the solution after filtering to obtain palladium precipitation and The slag after palladium precipitation, the palladium content of the palladium precipitation solution is 0.01mg / L, wherein the amount of ethyl xanthate added per liter of acid ...

Embodiment 2

[0029] Follow the steps below to recycle:

[0030] (1) High-acid leaching: high-acid leaching of the anode slime chlorinated slag, the leaching solution is a hydrochloric acid solution with an acidity of 6mol / L, the mass ratio of the leaching solution to the chlorinated slag is 5:1, the leaching temperature is 65°C, and the leaching time is For 2 hours, high-acid leaching solution and high-acid leaching slag were obtained, and the high-acid leaching slag was concentrated treatment;

[0031] (2) Ultrasonic precipitation of palladium: the anode slime high-acid leaching solution obtained in step (1) is placed in an ultrasonic device, the pH of the acid leaching solution is adjusted to 3.0 with sodium hydroxide, ethyl xanthate is added, and the solution after filtering to obtain palladium precipitation and The slag after palladium precipitation, the palladium content of the palladium precipitation solution is 0.05mg / L, and the amount of ethyl xanthate added per liter of acid leach...

Embodiment 3

[0037] Follow the steps below to recycle:

[0038](1) High-acid leaching: high-acid leaching of the anode slime chlorinated slag, the leaching solution is a hydrochloric acid solution with an acidity of 5mol / L, the mass ratio of the leaching solution to the chlorinated slag is 4:1, the leaching temperature is 50°C, and the leaching time is For 1 hour, high-acid leaching solution and high-acid leaching residue were obtained, and the high-acid leaching residue was concentrated treatment;

[0039] (2) Ultrasonic precipitation of palladium: the anode slime high-acid leaching solution obtained in step (1) is placed in an ultrasonic device, the pH of the acid leaching solution is adjusted to 0.6 with sodium hydroxide, ethyl xanthate is added, and the solution after filtering to obtain palladium precipitation and The slag after palladium precipitation, the palladium content of the palladium precipitation solution is 0.11mg / L, wherein the amount of ethyl xanthate added per liter of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com