Super-hydrophilic polymer microsphere and preparation method thereof and super-hydrophilic fabric prepared by preparation method

A polymer microsphere and super-hydrophilic technology, which is applied in the preparation of microspheres, microcapsule preparations, plant fibers, etc., can solve the problems that limit the application of textiles, achieve controllable particle size and surface morphology, and high roughness , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

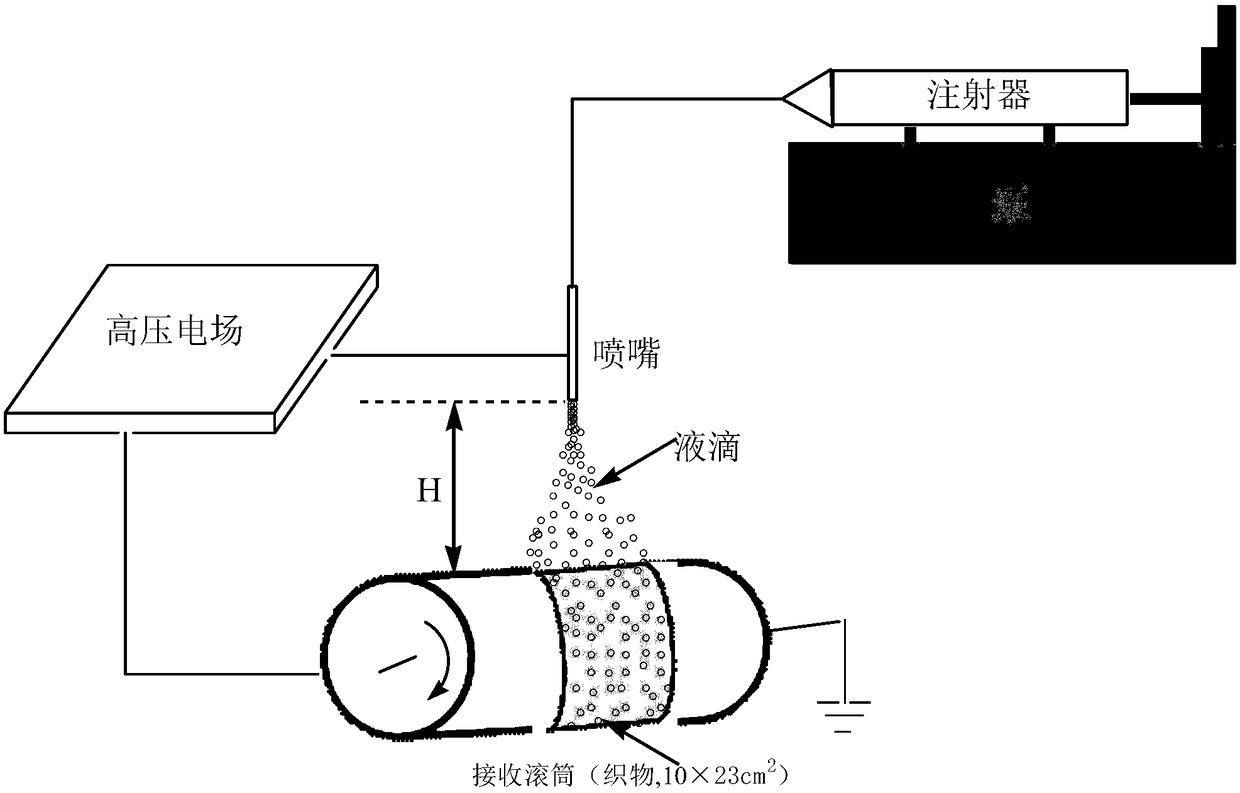

Method used

Image

Examples

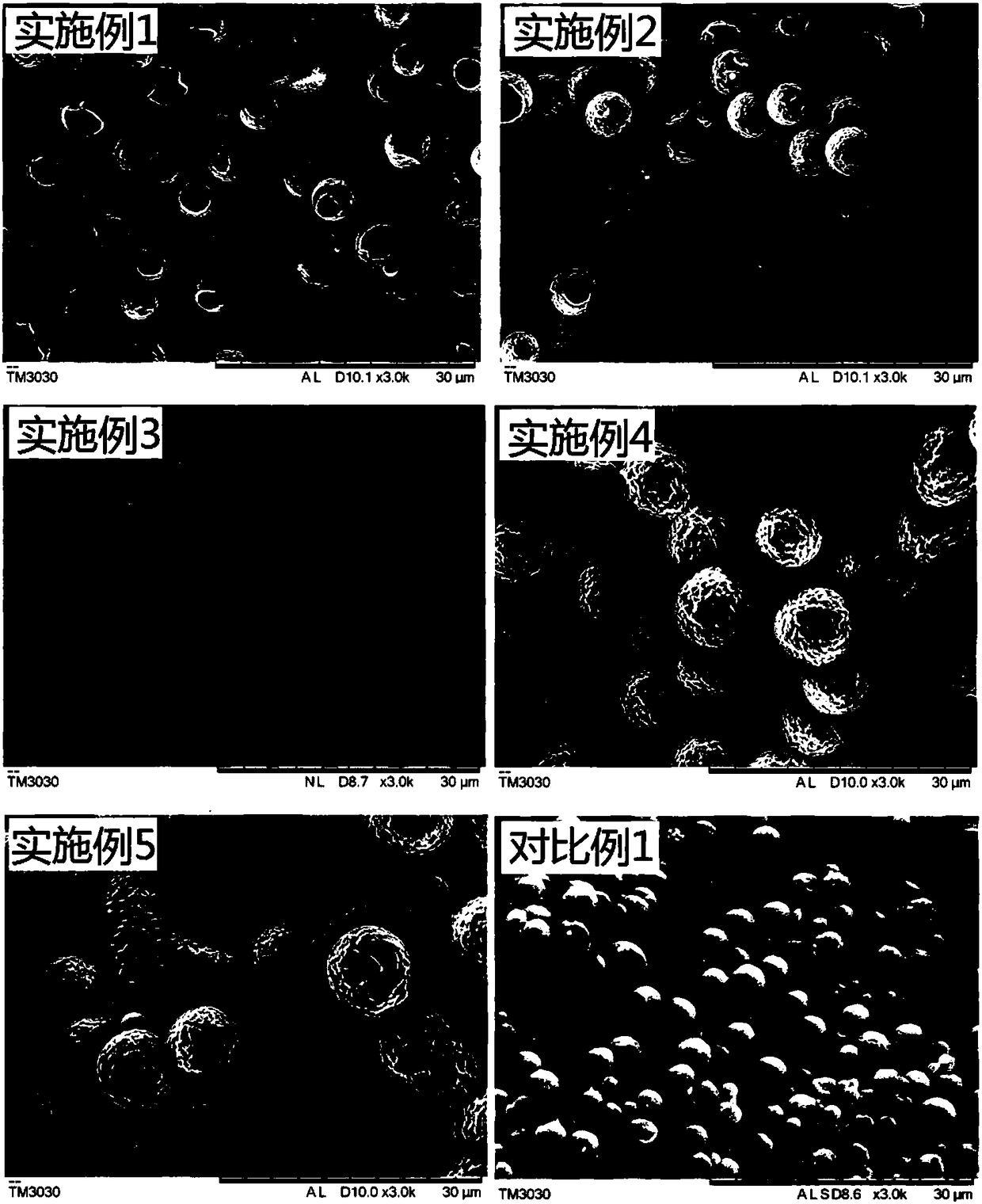

Embodiment 1

[0053] Add 10.1 g of carboxyl-terminated PCL with a number average molecular weight of 80,000, 1.62 g of N,N'-carbonyldiimidazole (CDI) and 100 mL of tetrahydrofuran (THF) into a 250 mL three-necked flask, and dissolve at room temperature. Under nitrogen protection, 1.2 g PEG-1000 was dissolved in 40 g tetrahydrofuran (THF), and added dropwise into a three-necked flask through a constant temperature and constant pressure funnel, and the dropwise addition was completed within 2 hours. After the addition was complete, the reaction was carried out at 35°C for 8 hours. After the reaction was over, the reaction solution was poured into 160g of petroleum ether, and a white solid was separated out by the anti-solvent method, filtered to obtain 9.6g of block-modified PCL product PEG1000-b-PCL, washed with ethanol and deionized water (v / v, 1 :1) Wash the mixed solution 4 times, using 300 g each time, and then wash 4 times with deionized water, using 600 g each time, put the obtained pr...

Embodiment 2

[0060] Add 11.6 g of carboxyl-terminated PCL with a number average molecular weight of 100,000, 1.62 g of N,N'-carbonyldiimidazole (CDI) and 110 mL of tetrahydrofuran (THF) into a 250 mL three-necked flask, and dissolve at room temperature. Under the protection of nitrogen, 4.1 g PEG-4000 was dissolved in 40 g tetrahydrofuran (THF), and added dropwise into a three-necked flask through a constant temperature and constant pressure funnel, and the dropwise addition was completed within 2 hours. After the addition was complete, the reaction was carried out at 35°C for 8 hours. After the reaction was over, the reaction solution was poured into 180g of petroleum ether, and a white solid was separated out by the anti-solvent method, filtered to obtain 13.7g of block-modified PCL product PEG4000-b-PCL, washed with ethanol and deionized water (v / v, 1 : 1) Wash the mixed solution 4 times, using 350 g each time, and then wash 4 times with deionized water, using 700 g each time, put the o...

Embodiment 3

[0065] Add 11.7 g of carboxyl-terminated PCL with a number average molecular weight of 100,000, 1.62 g of N,N'-carbonyldiimidazole (CDI) and 110 mL of tetrahydrofuran (THF) into a 250 mL three-necked flask, and dissolve at room temperature. Under nitrogen protection, 2.4 g PEG-2000 was dissolved in 35 g tetrahydrofuran (THF), and added dropwise into a three-necked flask through a constant temperature and constant pressure funnel, and the dropwise addition was completed within 1 hour. After the addition was complete, the reaction was carried out at 35°C for 8 hours. After the reaction was over, the reaction solution was poured into 150g of petroleum ether, and a white solid was separated out by the anti-solvent method, filtered to obtain 11.0g of block-modified PCL product PEG3000-b-PCL, washed with ethanol and deionized water (v / v, 1 : 1) Wash the mixed solution 4 times, using 250 g each time, and then wash 4 times with deionized water, using 500 g each time, put the obtained ...

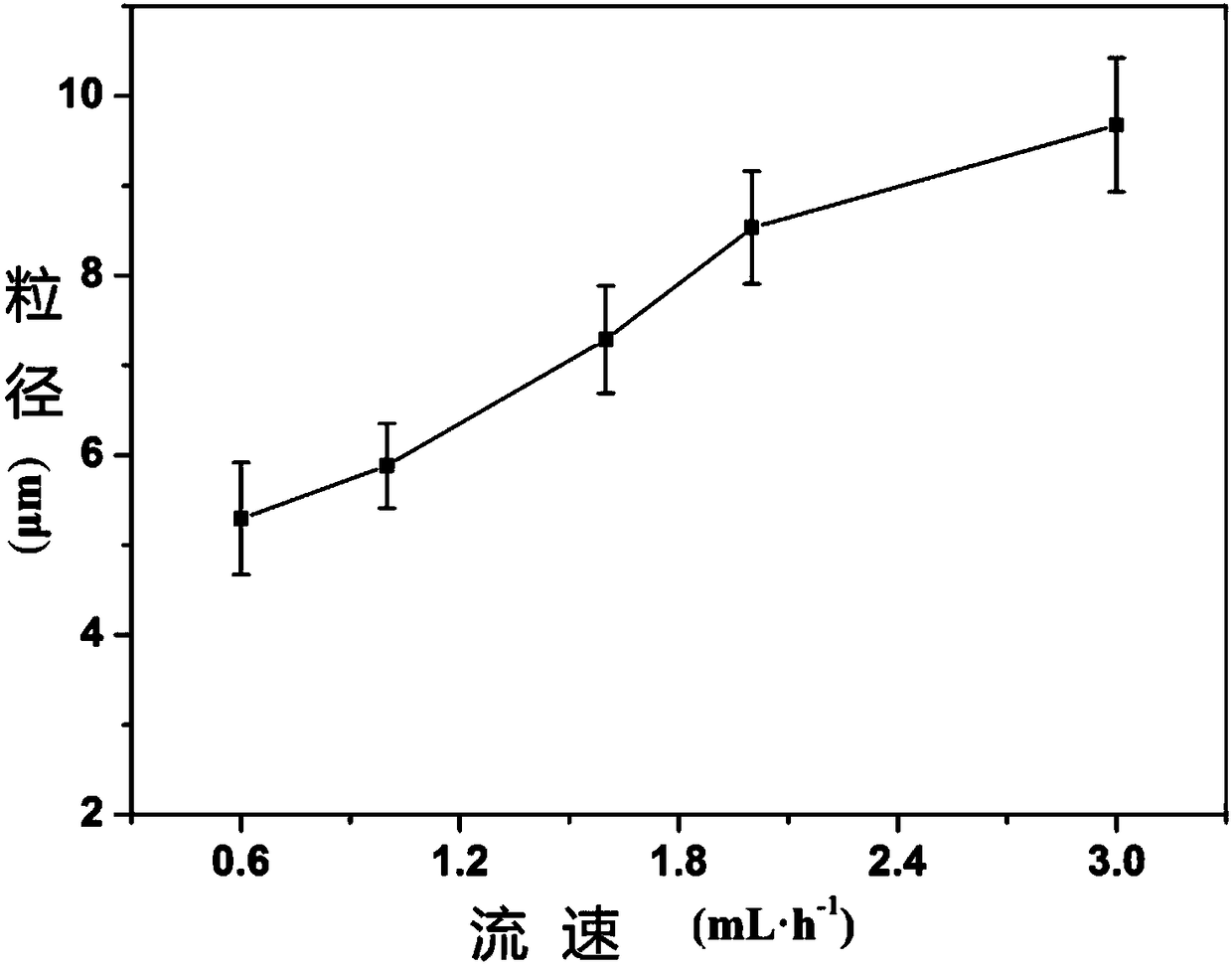

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com