Preparation method for high-grade borate type brake fluid

A borate and brake fluid technology, applied in the field of preparation of high-grade borate type brake fluid, can solve the problem of not considering the brake fluid rubber swelling, anti-rubber shrinkage hydrolysis stability, long reaction time, and many by-products. and other problems, to achieve the effect of increasing hydrolysis stability, reducing product cost, and overcoming the reduction in yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

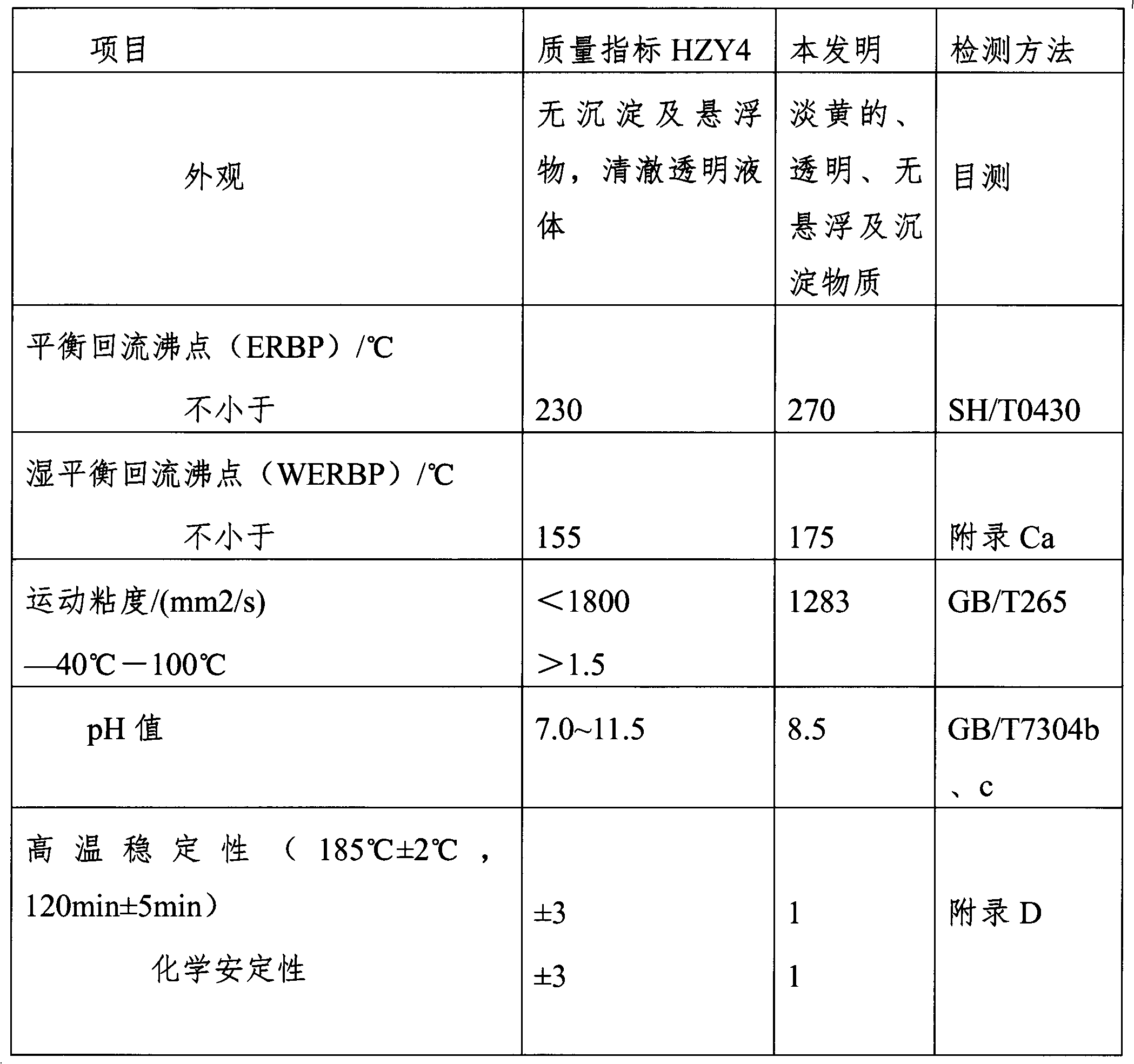

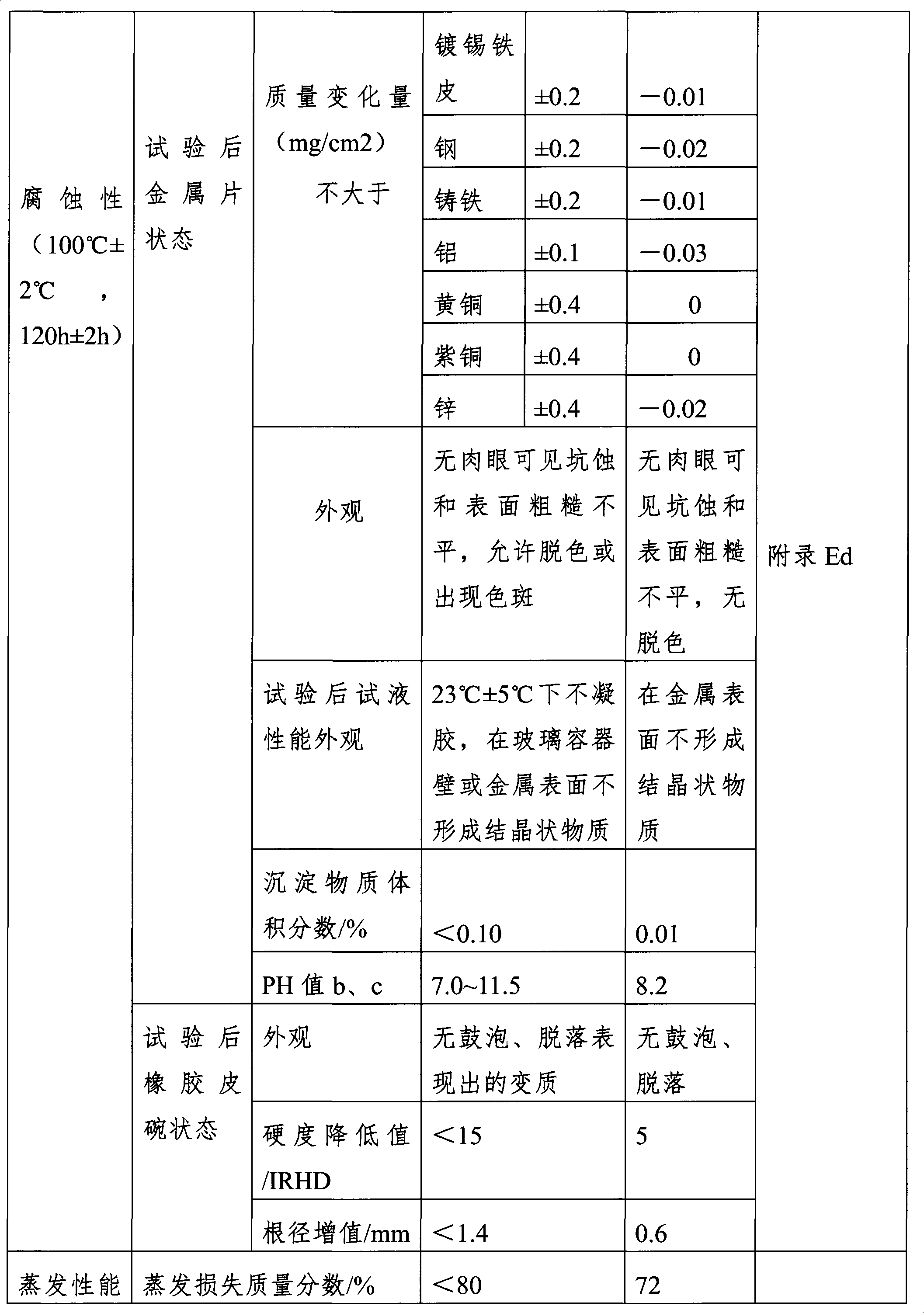

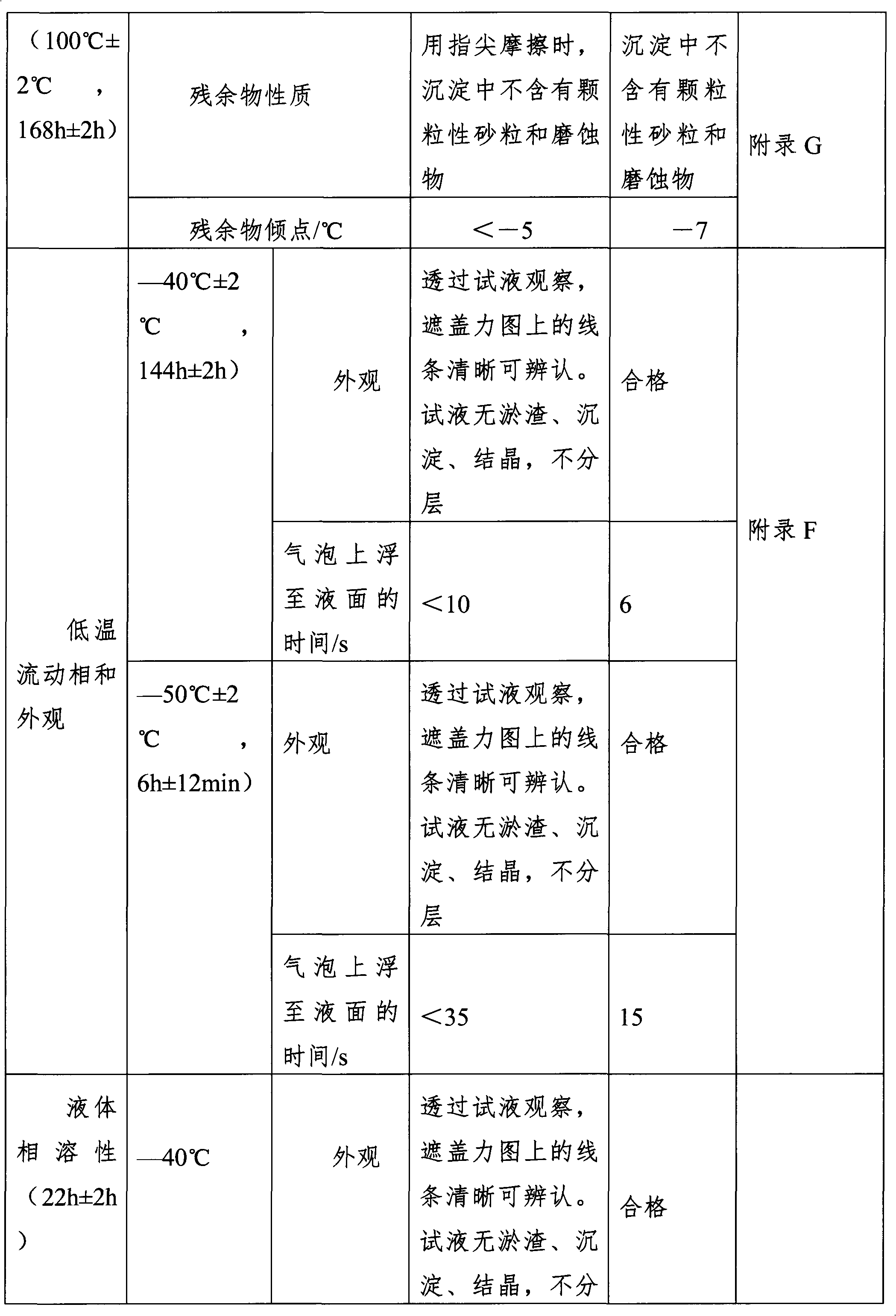

Examples

Embodiment

[0034] Take 64g of methanol, 464g of propylene oxide, and 1.5g of barium hydroxide into the autoclave, fill the autoclave with nitrogen to exhaust the air, pressurize to 0.3MPa, heat to 140°C, and the pressure rises to 1.8MPa. React for 2 hours. During this process, the temperature changes within 3°C, and the pressure drops slowly. When the pressure drops to about 0.7MPa, the polymerization is completed, stop heating, and after the product is cooled, add lactic acid to adjust the pH value to 7-9. A pale yellow polyalcohol ether is obtained. Carry out vacuum distillation under the pressure of 0.07-0.09Mpa, wherein 130 ℃ distillate is mono-, dipropanol monomethyl ether, as automobile brake fluid diluent, remaining after fractionation is tri-, tetrapropanol monomethyl ether, as Raw materials for the production of borate esters.

[0035]Take 264g of tri(tetra)propanol methyl ether, 10g of boric acid, and 25g of ethylene glycol and add them into a three-necked flask, feed nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com