Purification, separation and purification device for mixed gas of sulfur hexafluoride and nitrogen gas and sulfur hexafluoride recovery, purification and purification method

A technology of mixed gas and sulfur hexafluoride, applied in the fields of separation, sulfur hexafluoride gas recovery and purification, can solve the problems of high gas price, high liquefaction temperature, easy liquefaction, etc., achieve high economic and environmental benefits, improve gas Recovery rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

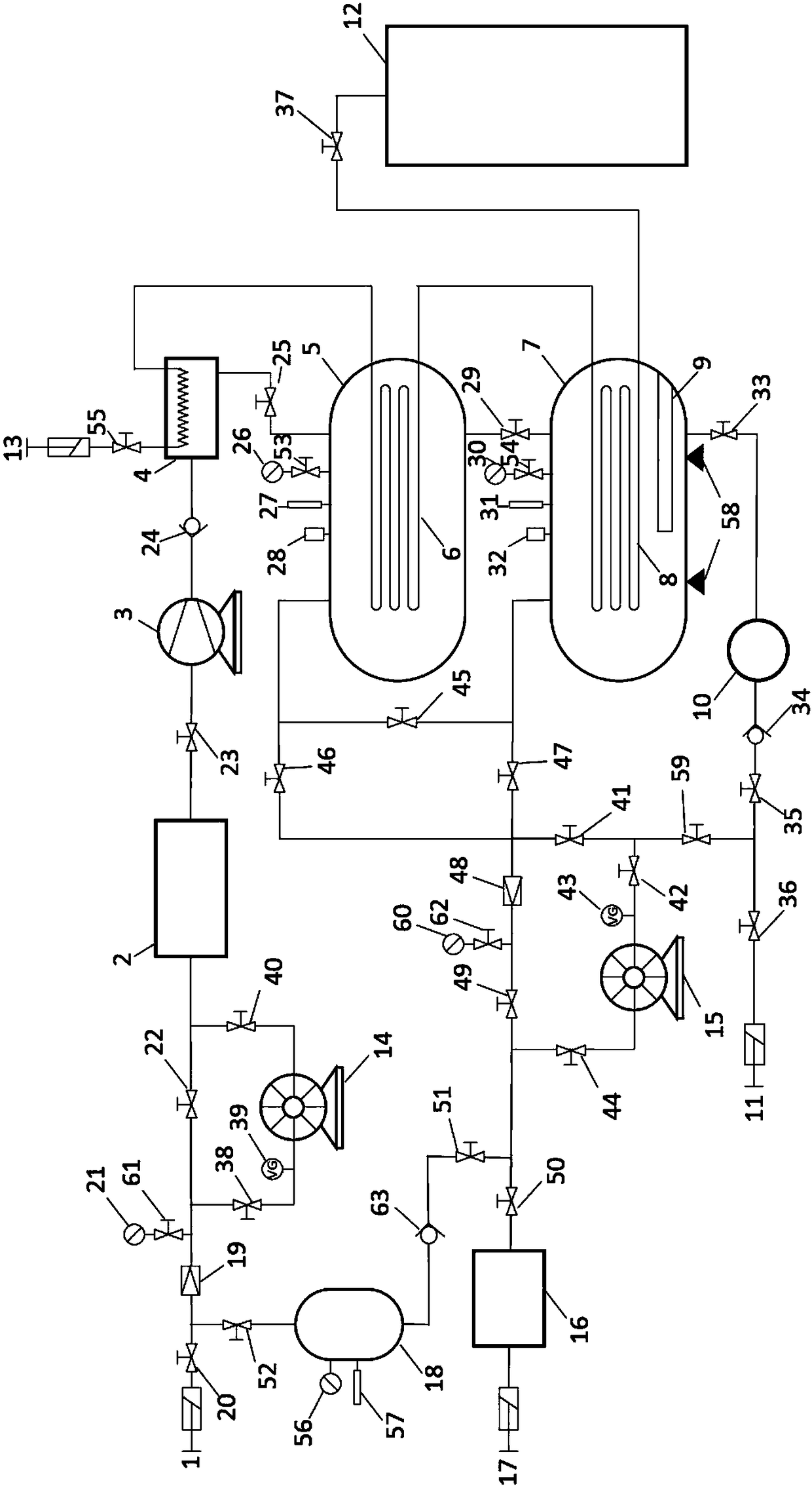

[0033] Such as figure 1 As shown, a sulfur hexafluoride and nitrogen mixed gas purification, separation and purification device includes a mixed gas inlet 1, a first vacuum pump 14, a gas purification device 2, a compressor 3, a dry shell-and-tube heat exchanger 4, a liquefaction Tank 5, first cooling medium channel 6, solidification tank 7, second cooling medium channel 8, weighing device 58, liquid injection pump 10, sulfur hexafluoride filling port 11, liquid nitrogen storage tank 12 (that is, liquid nitrogen Source), nitrogen gas outlet 13, second vacuum pump 15, tail gas treatment device 16, tail gas outlet 17 and circulating purification gas storage tank 18; wherein:

[0034] The mixed gas inlet 1 is sequentially provided with a first on-off valve 20, a first pressure regulating valve 19 (the pressure regulating valve is specifically a pressure reducing valve), a second on-off valve 22, a gas purification device 2, and a third on-off valve. 23. Compressor 3, first one-w...

Embodiment 2

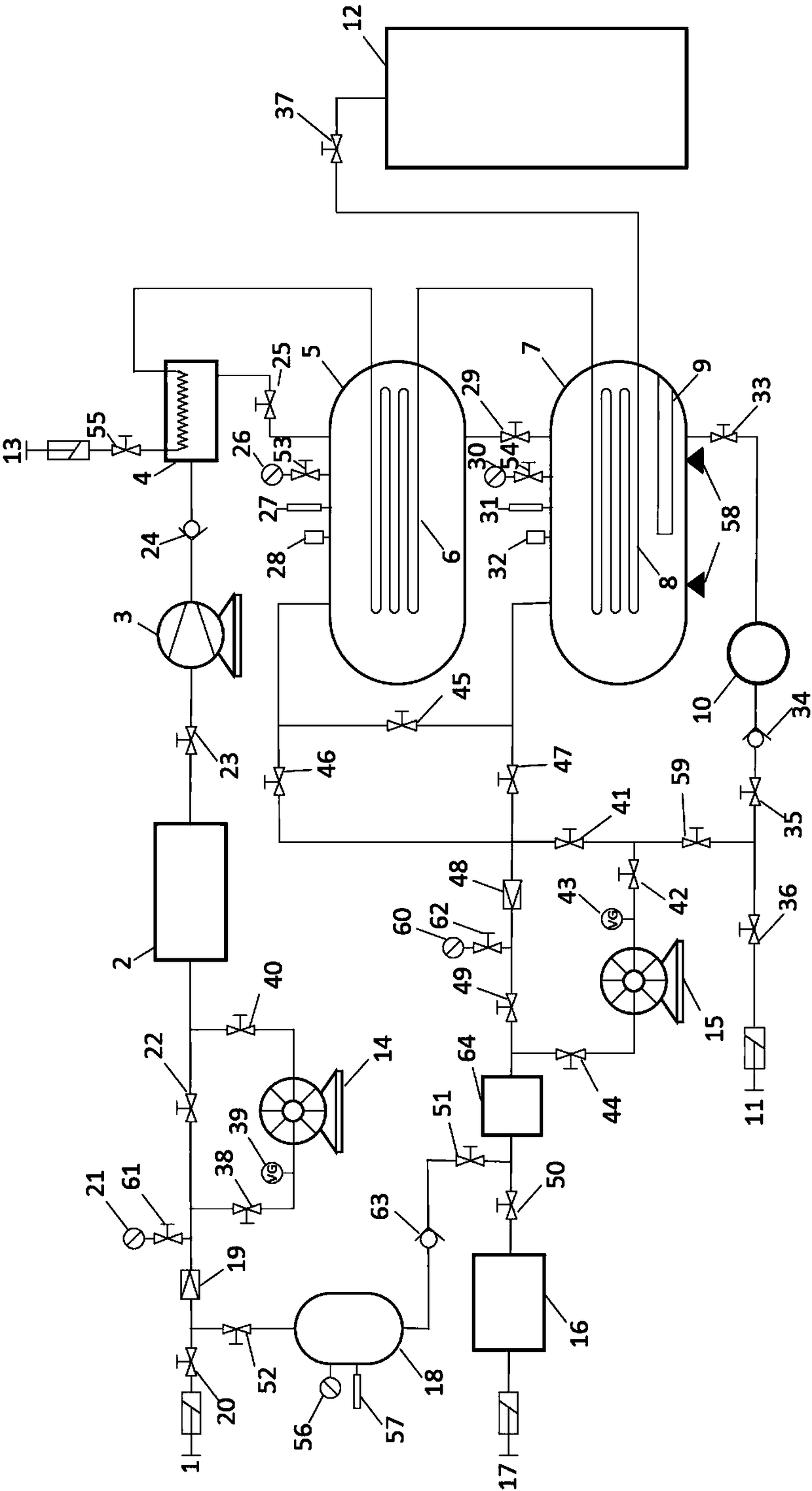

[0074] see figure 2 , as an improvement to Embodiment 1, in the middle of the connection between the nineteenth on-off valve 49 and the fifteenth on-off valve 44 and the connection between the twenty-fourth on-off valve 51 and the twentieth on-off valve 50 can be Add a pressure swing adsorption device 64, which is provided with Ca-A type artificial zeolite as the adsorbent in the pressure swing adsorption device 64;

[0075] The method for recovering, purifying and purifying sulfur hexafluoride of the improved scheme comprises the following steps:

[0076] Step one to step five are identical with step one to step five of embodiment 1;

[0077] 6. Recycling and purification of sulfur hexafluoride in impurity gas

[0078] After the solidification process is finished, the mixed gas in the liquefaction tank 5 and the solidification tank 7 is mainly nitrogen and a small amount of unsolidified sulfur hexafluoride saturated steam, and the fifth on-off valve 29 and the sixteenth on...

Embodiment 3

[0085] As an improvement to Embodiment 1 and Embodiment 2, the nitrogen gas outlet 13 is externally connected to a nitrogen gas recovery pipeline to recover the nitrogen gas discharged from the dry shell-and-tube heat exchanger 4 for backfilling into electrical equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com