Magnetic graphene oxide-chitosan composite material as well as preparation method and application thereof

A composite material and oxide stone technology is applied in the field of magnetic graphene oxide-chitosan composite material and its preparation, which can solve the problems of limited adsorption capacity of adsorbents, and achieves many adsorption sites, large specific surface area, and easy separation and recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of magnetic graphene oxide-chitosan composite material comprises the following steps:

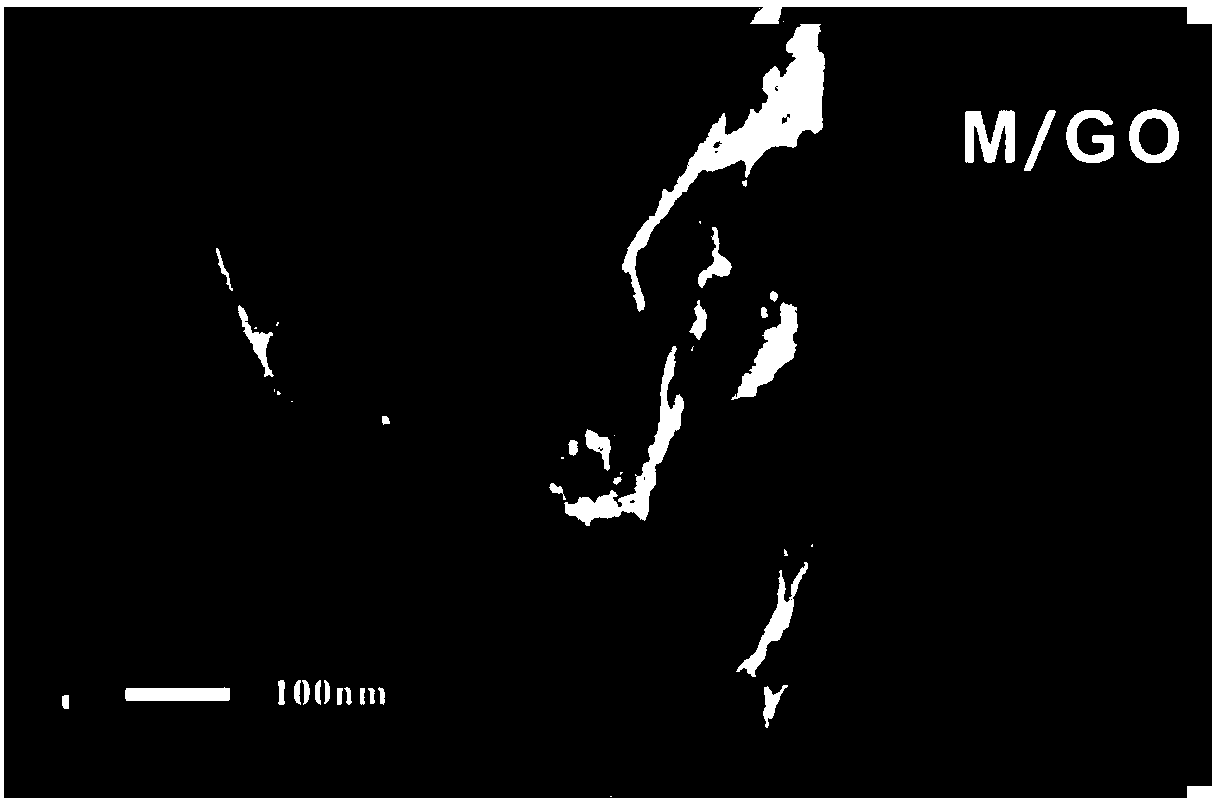

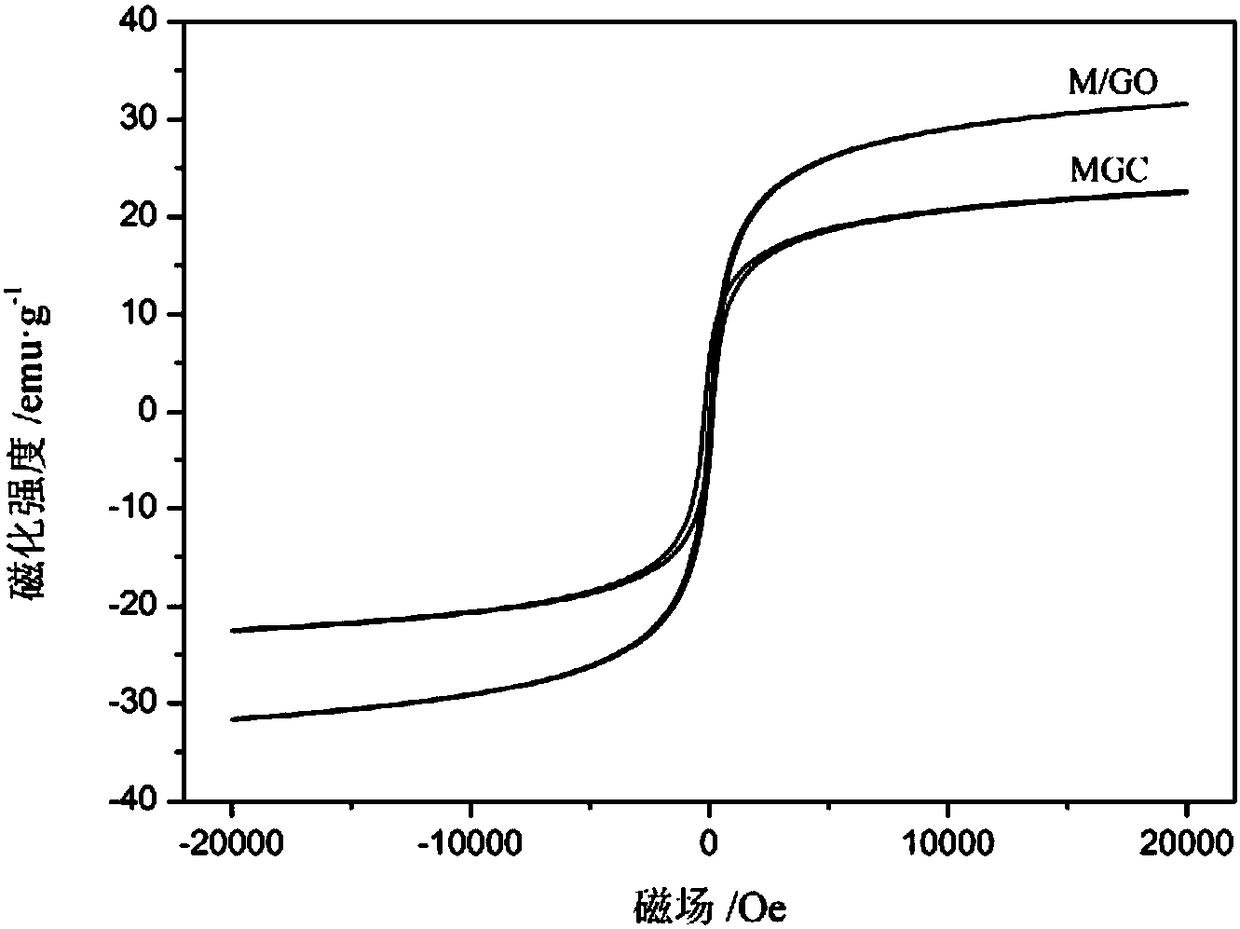

[0035] 1) Ultrasonic disperse 50mL of 1mg / mL graphene oxide for 30min. 0.5g FeCl 3 ·6H 2 O and 0.2gFeCl 2 4H 2 O was added into 25ml of ultrapure water and stirred to obtain an iron salt solution. Under the conditions of 60°C constant temperature water bath and nitrogen gas, add the graphene oxide dispersion liquid after ultrasonic in the round bottom three-neck flask, then add the iron salt solution, and then quickly add 30% ammonia water to make the pH of the mixed solution reach 10, at 300r The reaction was continued for 1 h with stirring. The obtained product was separated and collected by a magnet, washed five times with ultrapure water and absolute ethanol, and dried in a vacuum oven at 40° C. to obtain magnetic graphene oxide.

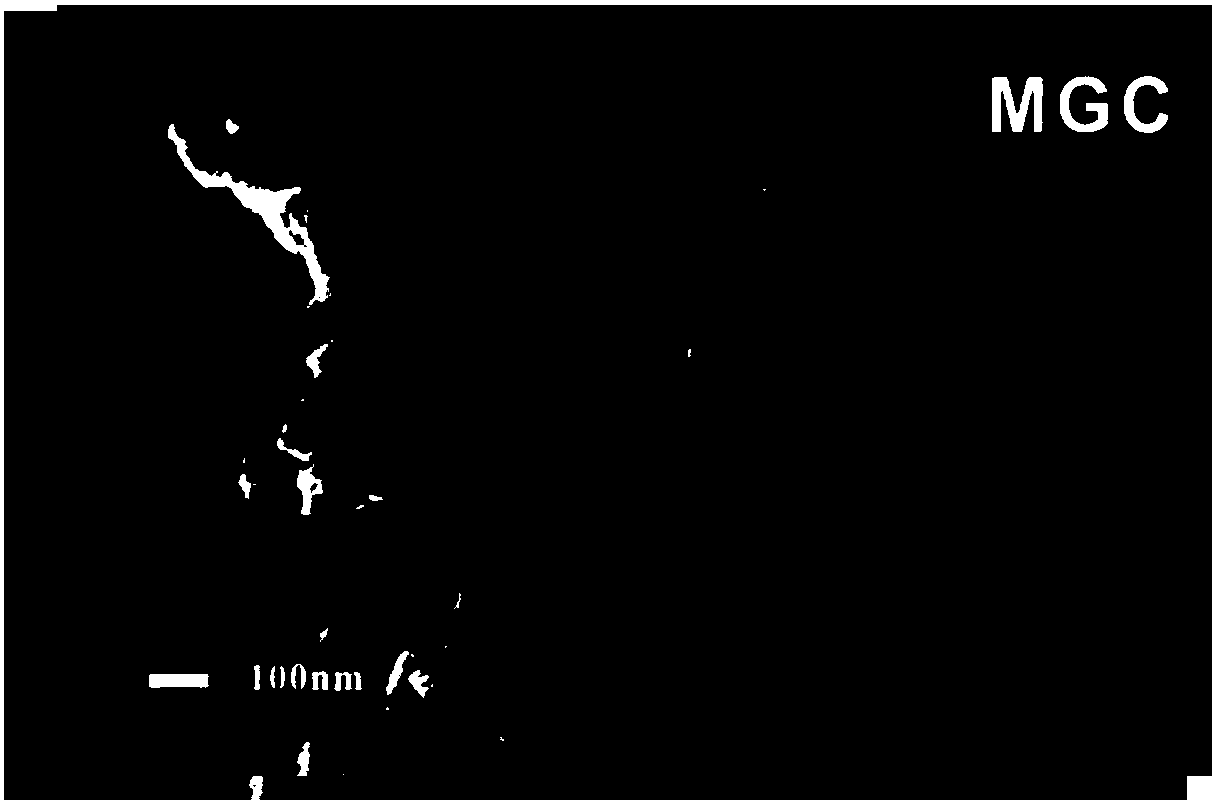

[0036] 2) Add 0.05 g of the prepared magnetic graphene oxide into 50 mL of ultrapure water for ultrasonic dispersion for ...

Embodiment 2

[0039] The magnetic graphene oxide-chitosan composite material prepared by embodiment 1 is applied to the adsorption treatment of Co(II), comprising the following steps: the background ion NaCl concentration is respectively 0.1mol / L, 0.01mol / L, 0.001mol / L In the case of L, add Co(II) solution in the magnetic graphene oxide-chitosan composite material solution, the concentration of magnetic graphene oxide-chitosan composite material in the mixed solution is 0.5g / L, Co(II) The concentration is 10mg / L; add HCl or NaOH to adjust the pH of the solution to 2-11 respectively; put it in an electrothermal constant temperature water bath shaking water tank for 300min to achieve adsorption equilibrium of Co(II) on magnetic graphene oxide-chitosan ; After separating the solid-liquid with a magnet, measure the unadsorbed Co(II) concentration in the solution at a wavelength of 578nm by using a UV spectrophotometer; calculate its adsorbed percentage according to the concentration difference o...

Embodiment 3

[0041] The magnetic graphene oxide-chitosan composite material prepared by embodiment 1 is applied to the adsorption treatment of Co(II), comprising the following steps: under the situation that the background ion NaCl concentration is 0.01mol / L, in the magnetic graphene oxide- Add Co(II) solution in the chitosan composite solution, the concentration of magnetic graphene oxide-chitosan composite in the mixed solution is 0.5g / L, and the Co(II) concentration is 10mg / L; add HCl or NaOH to adjust the solution pH to 7; placed in an electrothermal constant temperature water bath oscillating water tank for 5-300min respectively; after separating the solid-liquid with a magnet, measure the unadsorbed Co(II) concentration in the solution at a wavelength of 578nm with a UV spectrophotometer; The concentration difference of Co(II) in the solution, calculate the percentage of its adsorption, the result is as follows Figure 7 shown. It can be seen that: the adsorption reaction time is wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com