Method for ultrasonic-assistance laser near-net shape forming of titanium-nickel alloy gradient material

A laser near-net-shaping, ultrasonic-assisted technology, applied in the field of additive manufacturing, can solve the problems of uneven structure, limited manufacturing size, cracking, etc., achieve efficient preparation, avoid collapse problems, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

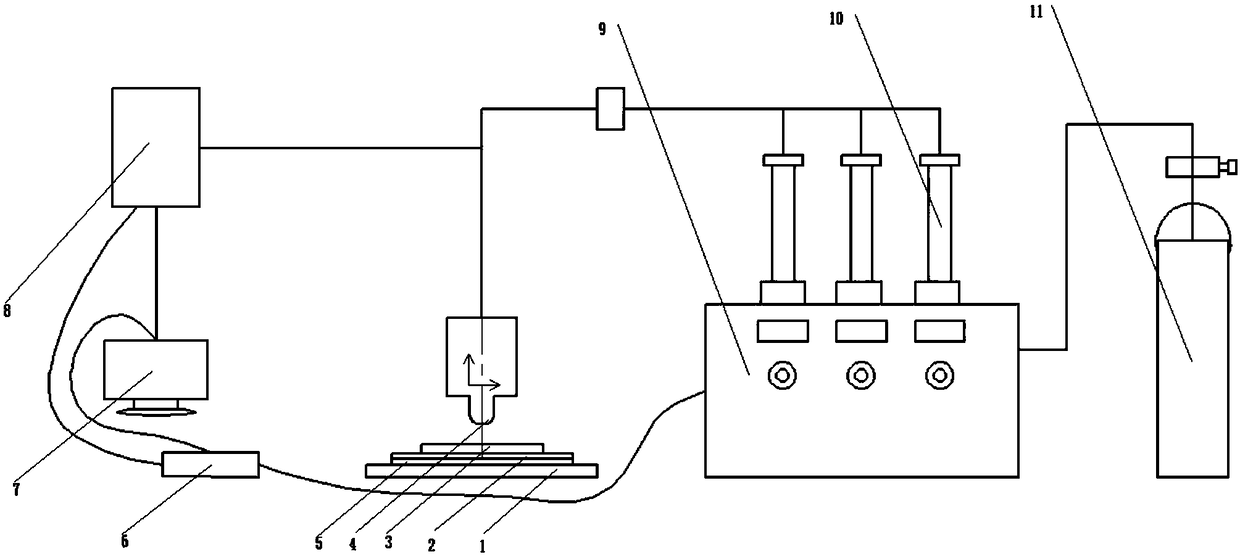

[0020] Nd:YAG solid-state continuous laser 8, ultrasonic auxiliary device 5, and preheating device 2 are used to perform laser near-net shaping of TC4 and GH4169 powders. The specific shaping steps are as follows:

[0021] A. The experimental substrate 3 is polished with sandpaper, washed with acetone and deionized water, and dried, and screened with a sieve for TC4 and GH4169 powders with a particle size of 45-90 μm, and put the screened powder of 45-90 μm into the electric heating drum Dry in an air drying oven at 100-120° C. for 4-6 hours, and put the two metal powders into the two cylinders 10 of the powder feeder 11 respectively.

[0022] B. Turn on the laser near-net shaping system, specifically including turning on the CNC machine tool, laser, cooling system, and control machine successively; fixing the ultrasonic generator 5 on the machine tool workbench, fixing the preheating device 2 on the ultrasonic generator 5, and then The substrate 3 is fixed on the preheating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com